- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1kg,5kg,15kg

-

Flux Content:

-

no

-

Warranty:

-

1 year

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

zander.welding.industry

-

Model Number:

-

ER316L stainless steel

-

Application:

-

for ultra-low carbon stainless steel.

-

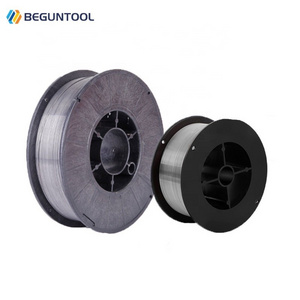

MIG diameter:

-

0.8mm 0.9mm 1.0mm 1.2mm 1.6mm

-

TIG diameter:

-

1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm

-

Raw material:

-

stainless steel alloy

-

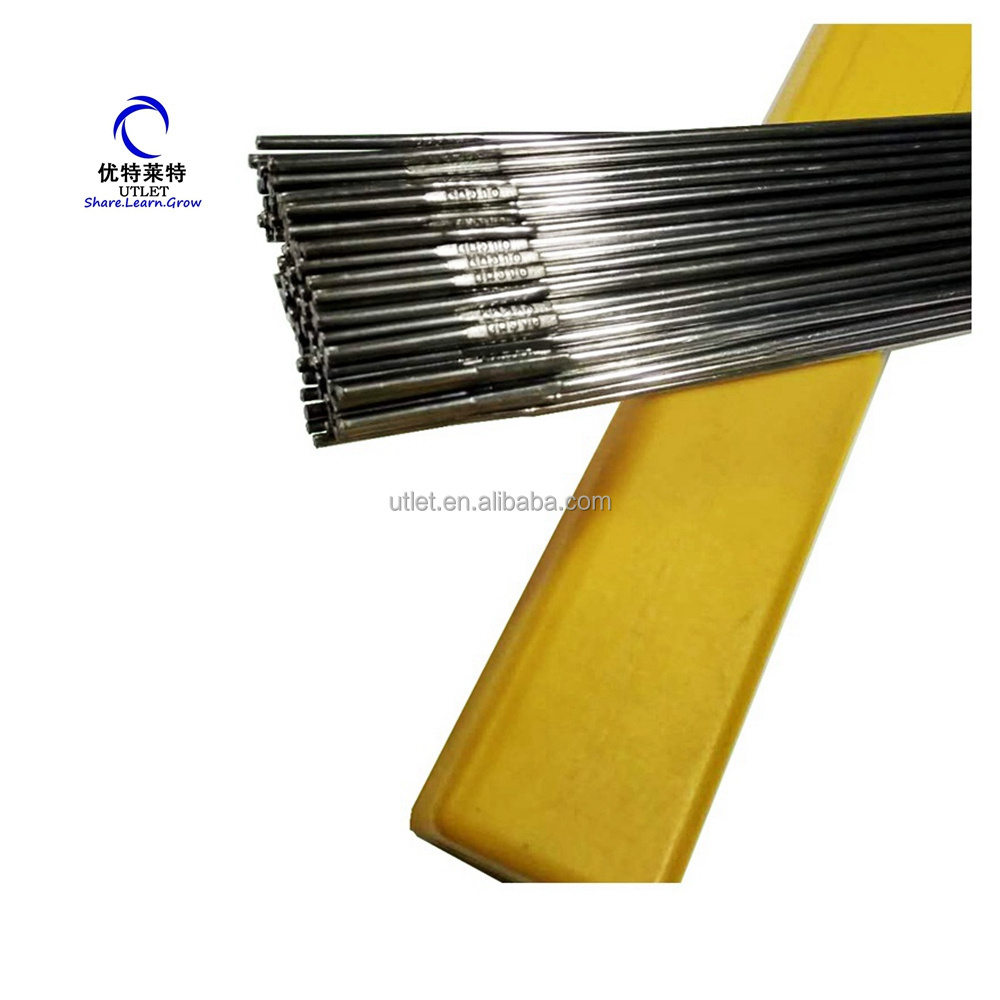

Packing 1:

-

D100-1kg

-

Packing 2:

-

D200-5kg

-

Packing 3:

-

D300-15kg

-

S-k-y-p-e:

-

zander.welding.industry

-

MOQ:

-

100 kgs

-

Delivery:

-

5-7 days

-

Product Keywords:

-

Stainless Steel Welding Filler Wire Er308

Quick Details

-

Material:

-

stainless steel welding

-

Diameter:

-

1.6 2.0 2.4 3.0 3.2 4.0mm

-

Melting Point:

-

2400

-

Weight:

-

1kg,5kg,15kg

-

Flux Content:

-

no

-

Warranty:

-

1 year

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

zander.welding.industry

-

Model Number:

-

ER316L stainless steel

-

Application:

-

for ultra-low carbon stainless steel.

-

MIG diameter:

-

0.8mm 0.9mm 1.0mm 1.2mm 1.6mm

-

TIG diameter:

-

1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm

-

Raw material:

-

stainless steel alloy

-

Packing 1:

-

D100-1kg

-

Packing 2:

-

D200-5kg

-

Packing 3:

-

D300-15kg

-

S-k-y-p-e:

-

zander.welding.industry

-

MOQ:

-

100 kgs

-

Delivery:

-

5-7 days

-

Product Keywords:

-

Stainless Steel Welding Filler Wire Er308

Stainless Steel Welding Filler Wire Er308

Product Detail

| MIG diameter | 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm |

| TIG diameter | 1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm |

| Raw material | stainless steel alloy |

| Packing 1 | D100-1kg |

| Packing 2 | D200-5kg |

| Packing 3 | D300-15kg |

| S-k-y-p-e | zander.welding.industry |

| MOQ | 100 kgs |

| Delivery | 5-7 days |

| Product Keywords | Stainless Steel Welding Filler Wire Er308 |

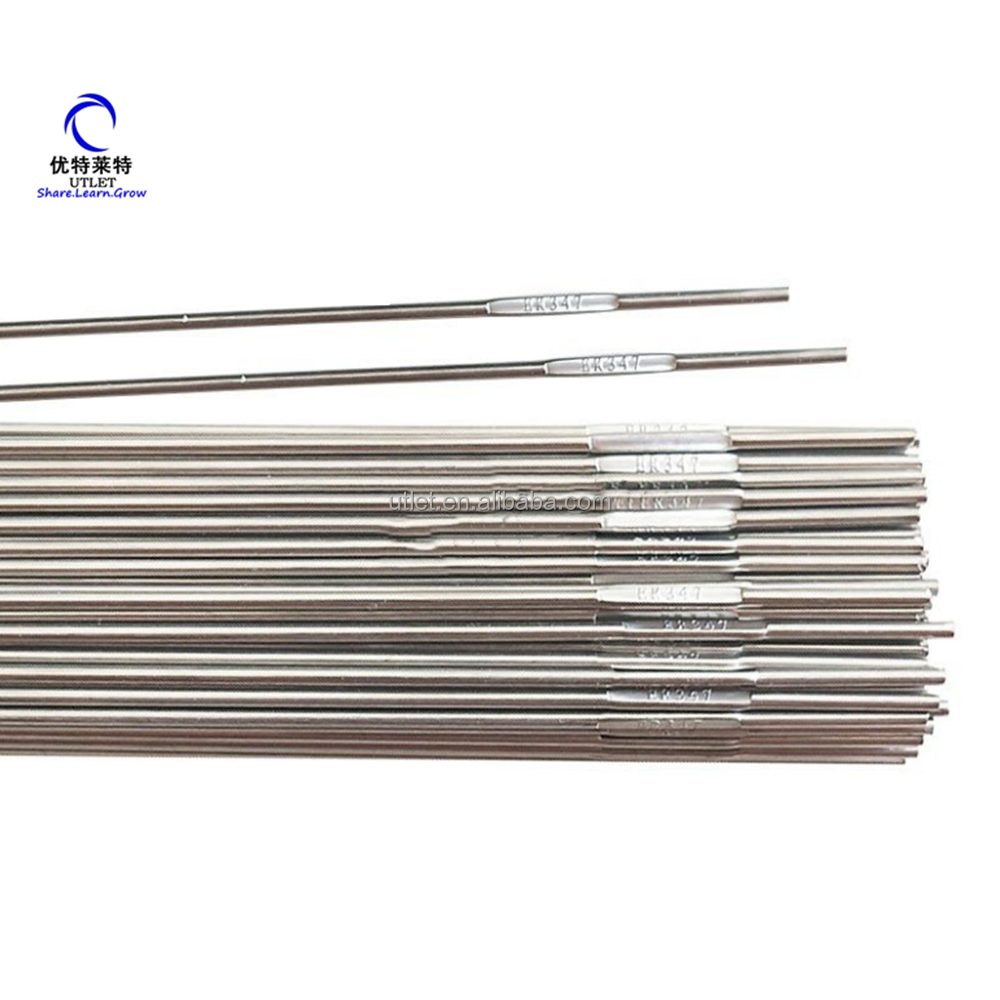

ER316

Description: ER316 is TIG welding wire for stainless steel. The weld metal is austenitic structure containing 19%Cr-12%Ni-2%Mo, which is excellent in corrosion resistance, heat resistance and crack resistance. Because Mo contains good corrosion resistance to acetic acid, sulfurous acid, phosphoric acid and salts, especially against chloride ion pitting.Uses: Used for the welding of the same type of stainless steel, but also for the welding of high-chromium steel and dissimilar steel without heat treatment after welding.

|

Item |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

|

Standard |

≤0.08 |

0.30-

|

1.00-

|

≤0.030 |

≤0.030 |

18.00-

|

11.00-

|

2.00-

|

≤0.75 |

|

Test |

0.048 |

0.43 |

1.78 |

0.012 |

0.010 |

19.23 |

12.5 |

2.52 |

0.30

|

ER 316L

Description: ER316L is a TIG welding wire for ultra-low carbon stainless steel. The weld metal is austenitic structure containing 19%Cr-12%Ni-2%Mo, which is excellent in corrosion resistance, heat resistance and crack resistance. Because Mo contains good corrosion resistance to acetic acid, sulfurous acid, phosphoric acid and salts, especially against chloride ion pitting.Uses: Used for welding welding of urea and synthetic fiber equipment. It can also be used for welding high-chromium steel and dissimilar steel without heat treatment after welding.

|

Item |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Cu |

|

Standard |

≤0.030 |

0.30-

|

1.00-

|

≤0.030 |

≤0.030 |

18.00-

|

11.00-

|

2.00-

|

≤0.75 |

|

Test |

0.022 |

0.42 |

1.89 |

0.009 |

0.007 |

19.12 |

12.62 |

2.62 |

0.34 |