- Product Details

- {{item.text}}

Quick Details

-

Max. Lifting Height:

-

100m

-

Span:

-

30m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dowell

-

Weight (KG):

-

15000 kg

-

Max working load:

-

15t

-

Max working radius:

-

30m

-

Max lifting height:

-

100m

-

Hoisting speed:

-

0-15m/min

-

Slewing angle:

-

360°

-

Slewing speed:

-

0.5r/min

-

Time of arm change:

-

120s

-

Hoisting motor power:

-

120Kw

-

Power source:

-

380v/50hz/customized

-

Colour:

-

customized

Quick Details

-

Application:

-

port,deck,plant,storage yard

-

Rated Loading Capacity:

-

1Ton-25Ton

-

Rated Lifting Moment:

-

6250Kn

-

Max. Lifting Height:

-

100m

-

Span:

-

30m

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dowell

-

Weight (KG):

-

15000 kg

-

Max working load:

-

15t

-

Max working radius:

-

30m

-

Max lifting height:

-

100m

-

Hoisting speed:

-

0-15m/min

-

Slewing angle:

-

360°

-

Slewing speed:

-

0.5r/min

-

Time of arm change:

-

120s

-

Hoisting motor power:

-

120Kw

-

Power source:

-

380v/50hz/customized

-

Colour:

-

customized

Products Description

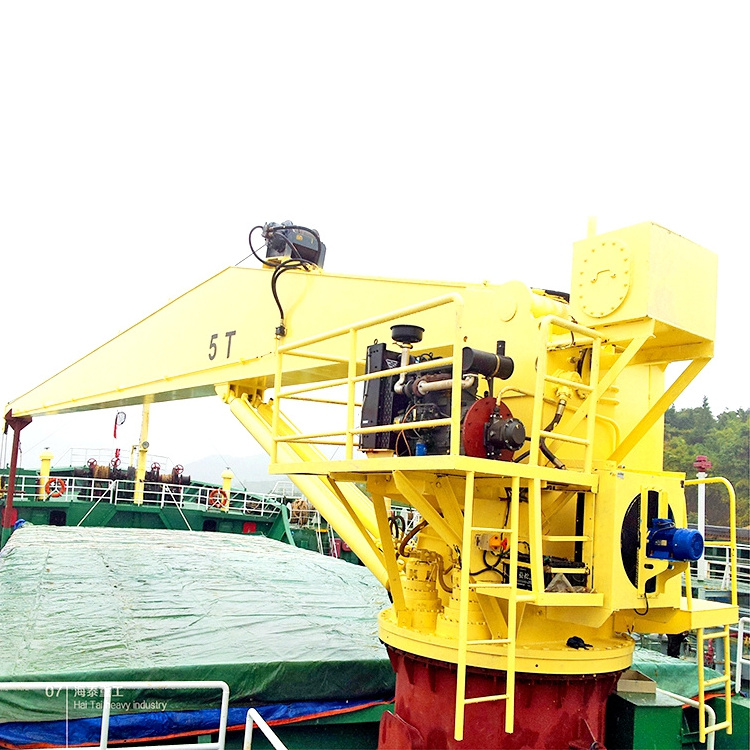

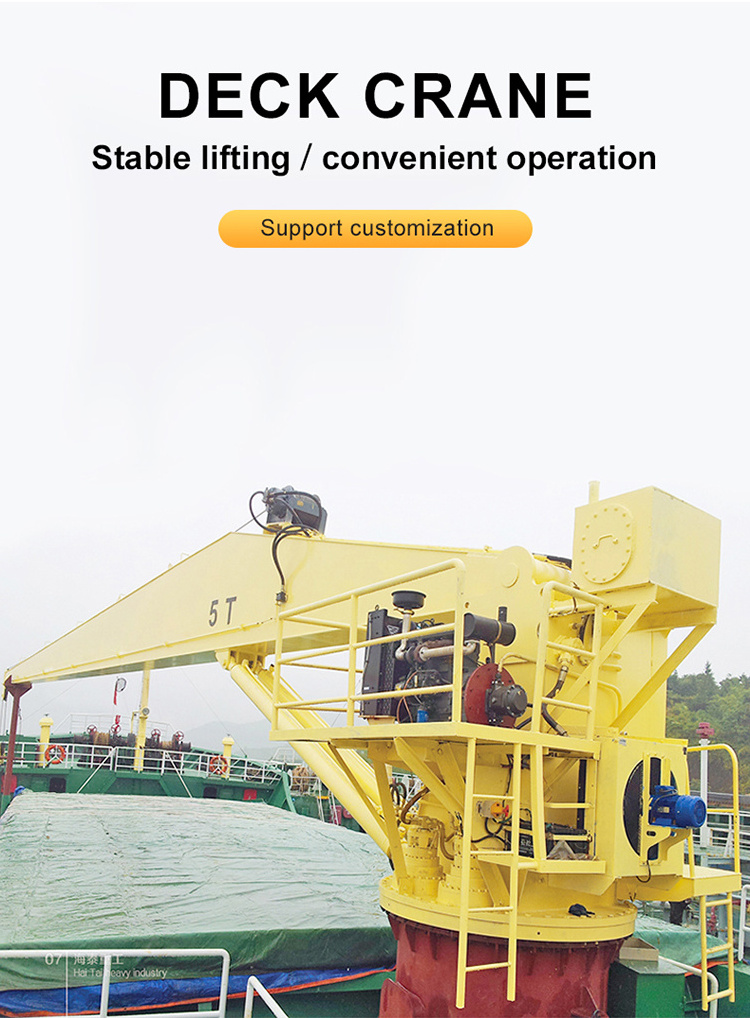

A deck crane is a type of crane that is specifically designed to be mounted on the deck of a ship or other vessels. They are used for a variety of tasks on board a vessel, including loading and unloading cargo, moving heavy equipment and machinery, and assisting with maintenance and repair operations.

Deck cranes come in a range of sizes and capacities, depending on the requirements of the vessel and the types of loads they will be expected to handle. They can be operated manually, or powered by electric or hydraulic systems. Some deck cranes are also equipped with telescoping booms or other features that allow them to reach over the sides of the vessel to load or unload cargo.

In addition to their use on ships and other seagoing vessels, deck cranes are also commonly used in ports and harbors, as well as in offshore oil and gas operations. They are an essential piece of equipment in the maritime industry, and play a critical role in keeping goods and materials moving around the world.

Application

Product Paramenters

|

Item

|

16T marine deck crane

|

25T marine deck crane

|

|

Motor Power

|

24KW

|

45KW

|

|

Lifting height

|

33M-35M

|

21M

|

|

Swing speed

|

2.6R/MIN

|

2R/MIN

|

|

Boom material

|

steel plate

|

Q345 steel plate

|

|

Rated tonnage

|

16T

|

25T

|

|

Jib length

|

7M-7.5M

|

10M*2

|

|

Rotation angle

|

360°

|

360°

|

|

Cooling method

|

Forced air cooling

|

Forced air cooling

|

Safety devices

1. Anti-two block system: A device that prevents the crane's hook block from colliding with the boom tip or other parts of the crane. The anti-two block system will automatically stop the hoist if the hook block gets too close to the boom tip or other obstructions. 2. Emergency stop button: A large, easily accessible button that allows the operator to quickly stop all crane movements in an emergency situation.

1. Anti-two block system: A device that prevents the crane's hook block from colliding with the boom tip or other parts of the crane. The anti-two block system will automatically stop the hoist if the hook block gets too close to the boom tip or other obstructions. 2. Emergency stop button: A large, easily accessible button that allows the operator to quickly stop all crane movements in an emergency situation.

3. Limit switches: Switches that limit the range of movement of the crane's hoist, boom, or other components. For example, a hoist limit switch may prevent the hoist from lifting the load beyond a certain height.

4. Overload protection: A system that prevents the crane from lifting loads that are too heavy for its SWL. This may include mechanical stops, hydraulic pressure relief valves, or other devices.

5. Area protection: Sensors orother devices that help prevent collisions with other cranes, vessels, or structures in the crane's operating area. This may include proximity sensors, cameras, or audible alarms.

6. Emergency lowering system: A system that allows the crane's load to be safely lowered to the ground in the event of a power failure or other emergency situation.

Details Images

Our Advantages

Product packaging

1.Hoist and electric parts will be packed by plywood crate, for avoiding the demage from goods crash and impact during the delivery.

2.Girders and other main parts will be packed by plastic woven cloth, for preventing rust from soppy condition during the transportation.

3.Only the best transport solution will be taken for saving your cost uttermost on finance,security and time.

Exhibition

After-sale Service

Hot Searches