- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

xzwd

-

Place of Origin:

-

Jiangsu, China

-

Brand:

-

xzwd

-

OEM service:

-

provided

-

Row material certification:

-

3.1 Certificate

-

Inspect report:

-

BV,CCS

-

Warranty:

-

1 year

-

Quality control:

-

ISO,CCS

-

Application:

-

Excavator Accessories

-

Hardness:

-

229-269H (slewing Bearing)

-

Product Name:

-

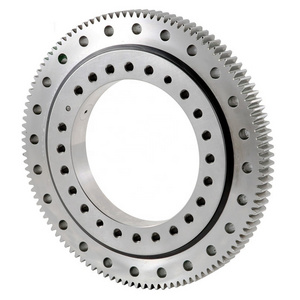

Swing Bearing customized for excavator

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Machinery Repair Shops, Farms, Construction works , Energy & Mining, Other

-

Feature:

-

Four Point Contact

-

Seals Type:

-

NBRI-3

-

Brand Name:

-

xzwd

-

Place of Origin:

-

Jiangsu, China

-

Brand:

-

xzwd

-

OEM service:

-

provided

-

Row material certification:

-

3.1 Certificate

-

Inspect report:

-

BV,CCS

-

Warranty:

-

1 year

-

Quality control:

-

ISO,CCS

-

Application:

-

Excavator Accessories

-

Hardness:

-

229-269H (slewing Bearing)

-

Product Name:

-

Swing Bearing customized for excavator

Main products

Single-row ball

Double-row different ball

Three-row roller

Cross roller

Ball & roller

Double-row ball

|

Raceway center diameter

|

Plane deviation of mounting bracket P (mm)

|

|

|

||

|

DL(mm)

|

single row four ball

|

double row ball

|

cross roller

|

||

|

~1000

|

0.15

|

0.20

|

0.1

|

||

|

>1000~1500

|

0.19

|

0.25

|

0.12

|

||

|

>1500~2000

|

0.22

|

0.30

|

0.15

|

||

|

>2000~2500

|

0.25

|

0.35

|

0.17

|

||

|

>2500~4000

|

0.30

|

0.40

|

0.20

|

||

|

>4000~6000

|

0.40

|

0.50

|

0.30

|

||

|

>6000~8000

|

0.50

|

0.60

|

0.40

|

||

Production Process

Forging

Forging material: 50Mn, 42CrMo, etc.

Rough Turning

Processing rang: 100-4500mm

Processing precision: Grade IT 10

Raceway Rough Turning

Processing range: 100-4500mm

Processing precisiong: Grade IT 8

Raceway Heat Treatment

Hardness range: 55-62HRC

Quenching depth: 2-8mm

Automatic tracking

Real-time monitoring

Gear Making

Processing range:100-3500mm

Processing precisiong: Grade 8-10

Gear Heat Treatment

Hardness range: 50-60HRC

Quenching depth: 0.6-4mm

Automatic tracking

Real-time monitoring

Surface Finish Turning

Processing range: 100-4500mm

Processing precision: Grade IT 7-IT 10

Surface roughness:3.2, 6.3

Hole Drilling

Processing range:100-4500mm

Position precision: 0.5mm

Raceway Finish Turning

Processing range:100-4500mm

Processing precision: Grade 7-8

Surface roughness: 0.8-1.6

Deburring and Cleaning

Deburring items: plug, soft zone, tooth chamfer, descaling, cleaning, etc.

Assembling

Assembling range:100-4500mm

Inspection

Full size inspection: dimensional accuracy, raceway hardness, axial clearance, radial clearance, axial runout, gear radial runout, gear accuracy, tooth surface hardness, rotational flexibility, appearance, documentation, etc.

Gear Heat Treatment

The raceway heat treatment of the slewing bearing is realized by induction heat treatment technology. Xuzhou Wanda Slewing Bearing has advanced heat treatment equipment (processing equipment and testing equipment) and scientific processing technology, so that the depth and hardness of the hardened layer conform to JB /T2300-2018 slewing bearing standard.

Quality Control

The company has passed ISO9001 Quality Management System, ISO14001 Environmental Management System certification and China Classification Society (CCS) supplier certification.

Three Coordinates

It is used to detect the straightness, flatness, roundness, cylindricity, profile, perpendicularity, parallelism, inclination,

coaxiality, concentricity, symmetry, position, compound position, curve profile, Surface profile, radial circular runout, radial full runout, end face circular runout, end face full runout, etc.

Measuring range:X=1000,Y=2000,Z=800mm;

Measuring accuracy:3.0 +L/250 µm(L:mm)

Ultrasonic Surface Hardening Layer Thickness Gauge

Imported advanced equipment is used to detect the depth of induction hardened layer on the surface of various steel materials(non-destructive testing). Hard layer depth detection after raceway heat treatment (no slicing, direct measurement).

The company has complete research and development, verification and inspection equipment, and currently there are more than 20 kinds of equipments in the factory, including automatic turret microhardness tester, microcomputer-controlled universal testing machine, metallographic microscope, magnetic particle flaw detector, digital ultrasonic flaw detector, bearing measuring instrument, Leeb hardness tester, ultrasonic surface quenching layer thickness gauge, three coordinates, etc. A variety of testing and control methods are used to escort the manufacture of high-quality products.

Hot Searches