- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

130000

-

Power (kW):

-

100

-

Product name:

-

Balloon Making Machine

-

After-sales Service Provided:

-

Engineers

-

Application:

-

balloon dipping line

-

Workshop:

-

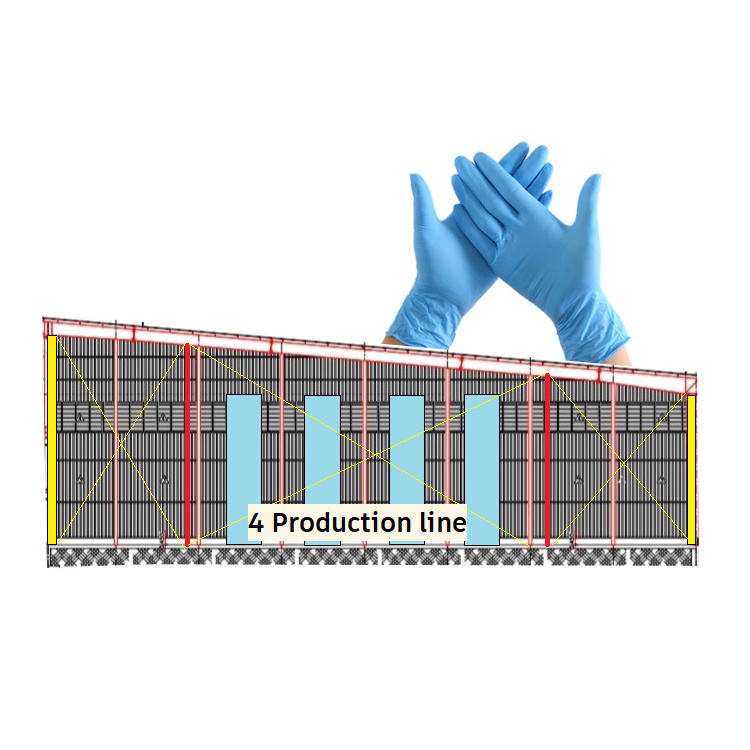

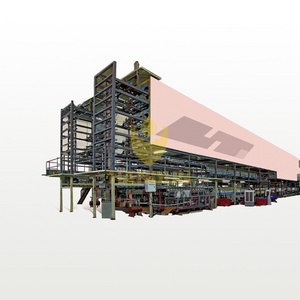

140 x4.5 x5.7m

-

Capacity(24H):

-

3T

-

Mold quantity:

-

130000pcs

-

Workers:

-

7

-

Power:

-

100Kw

-

natural Gas consumption(m³):

-

1800

-

Usage of Latex:

-

5 tons

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V,220V

-

Dimension(L*W*H):

-

120x1.4x5.7m

-

Weight:

-

130000

-

Power (kW):

-

100

-

Product name:

-

Balloon Making Machine

-

After-sales Service Provided:

-

Engineers

-

Application:

-

balloon dipping line

-

Workshop:

-

140 x4.5 x5.7m

-

Capacity(24H):

-

3T

-

Mold quantity:

-

130000pcs

-

Workers:

-

7

-

Power:

-

100Kw

-

natural Gas consumption(m³):

-

1800

-

Usage of Latex:

-

5 tons

Low price nitrile Glove Machine Making glove Maker Machine in China

Product Description

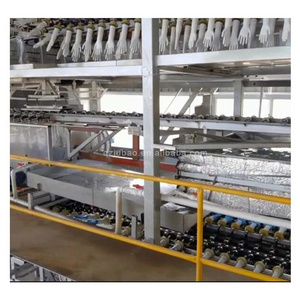

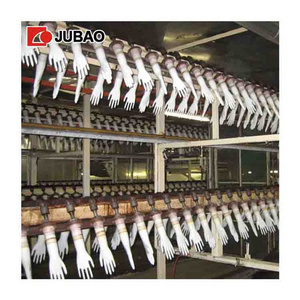

1. The natural latex toy glove production line adopts continuous production method and direct immersion method, ballon film formation is uniform and color is bright. Various specifications and special-shaped balls can be produced at the same time, and balloons of various specifications and colors can be produced at the same time; the length of the production line can be 30 meters, 60 meters, 80 meters and 100 meters etc. ballons can automatically demoulded and have no sag points.

2. The machine is humanized designed according to the natural latex curing and molding process. Reasonable process and automatic balance glue system makes the product stable, the thickness and length of glove coating is uniform, glovess can be heated evenly. the output is high, and the demoulding is easy and simple.

3. The oven adopts the principle of hot air circulation to make the internal temperature of the oven uniform. The use of chemical fiber asbestos thermal insulation materials can effectively ensure that the temperature will not lost, thereby improving the use of machine thermal efficiency. The machine heating system adopts PID temperature intelligent instruments and high-performance control switches to improve accuracy of temperature control, thereby improving the pass rate of products.

2. The machine is humanized designed according to the natural latex curing and molding process. Reasonable process and automatic balance glue system makes the product stable, the thickness and length of glove coating is uniform, glovess can be heated evenly. the output is high, and the demoulding is easy and simple.

3. The oven adopts the principle of hot air circulation to make the internal temperature of the oven uniform. The use of chemical fiber asbestos thermal insulation materials can effectively ensure that the temperature will not lost, thereby improving the use of machine thermal efficiency. The machine heating system adopts PID temperature intelligent instruments and high-performance control switches to improve accuracy of temperature control, thereby improving the pass rate of products.

Specification

We are offering an high end quality of Latex glove Making Machinery to our clients. These are well appreciated for its qualitative features all across the globe.

These are recognized in the market for long functional life, dimensional accuracy, high performance, and low maintenance requirement. These are widely known for its quality and our energy efficient, durable, easy to use and maintain range is widely used in various industries. These are widely appreciated by our clients.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches