- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huan

-

Year:

-

Customized

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5*5.9*3.1m

-

Hollow part volume:

-

30L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

16.5 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1100 mm

-

Mold Platen Size(Height)(mm):

-

430 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.5 m³/min

-

Die Head Heating Power(kW):

-

21 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

160

-

Weight (T):

-

12

-

Model Number:

-

HJS90FS

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Material:

-

PE,PP,PVC,PA...

-

Machine type:

-

Extrusion blow moulding machine

-

Range:

-

0-30L plastic bottle

-

Production:

-

hdpe extrusion blow molding machine

-

Product name:

-

30L jerry can making machine

Quick Details

-

Clamping Force (kN):

-

350

-

Output (kg/h):

-

150 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huan

-

Year:

-

Customized

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

5*5.9*3.1m

-

Hollow part volume:

-

30L

-

Screw L/D Ratio:

-

24

-

Screw diameter (mm):

-

90 mm

-

Screw Heating Power(kW):

-

16.5 kW

-

Extruder Motor Power(kW):

-

45 kW

-

Mold Platen Size(Width)(mm):

-

1100 mm

-

Mold Platen Size(Height)(mm):

-

430 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Air Comsumption(m³/min):

-

1.5 m³/min

-

Die Head Heating Power(kW):

-

21 kW

-

Accumulator Capacity(L):

-

0 L

-

Power (kW):

-

160

-

Weight (T):

-

12

-

Model Number:

-

HJS90FS

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Material:

-

PE,PP,PVC,PA...

-

Machine type:

-

Extrusion blow moulding machine

-

Range:

-

0-30L plastic bottle

-

Production:

-

hdpe extrusion blow molding machine

-

Product name:

-

30L jerry can making machine

Product Description

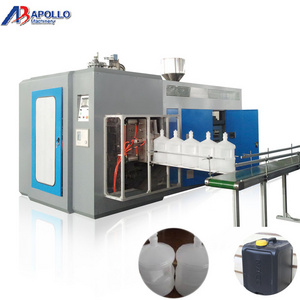

1.HJS90FS is two stage stucture machine,mould platen movement stroke can be enlarged.

2.Servo hydraulic system is standard coniguration.

3.Two layer and view line co extruder system is optional.

4.Single head ,suitable for below 20-30L liter products.

5.3 head,suitable for below 5 liter products.

6.8 head,suitable for below 1 liter products.

|

SPECIFICATIONS

|

HJS90FS

|

EXTRUSION UNIT

|

|

|

Material

|

PE PP PVC PA...

|

Screw diameter

|

90mm

|

|

Max container capacity

|

10L

|

Screw L/D ratio

|

24 L/D

|

|

Number of die

|

1,2,3,4,6,8

|

(HDPE) Plasticizing capacity

|

150kg/h

|

|

Machine Dimension(LxWxH)

|

5x5.9x3.1

|

Screw heating zone

|

4 zone

|

|

Total weight

|

12ton

|

Screw heating power

|

16.5kw

|

|

CLAMPING UNIT

|

|

Screw fan power

|

0.14kw

|

|

Clamping force

|

350kN

|

Extrusion motor power

|

45kw

|

|

Platen openning stokes

|

240-560mm

|

ENERGY CONSUMPTION

|

|

|

Carriage stroke

|

1150mm

|

Total power of machine

|

160kw

|

|

Max mould size(WxH)

|

1100x430mm

|

Power of oil pump motor

|

31kw

|

|

DIE HEAD

|

|

Air pressure

|

0.6-0.8 Mpa

|

|

Die head heating zone

|

16 zone

|

Average energy consumption

|

80kw

|

|

Power of die heating

|

21kw

|

Consumption compression air

|

1.5m3/min

|

Product Details

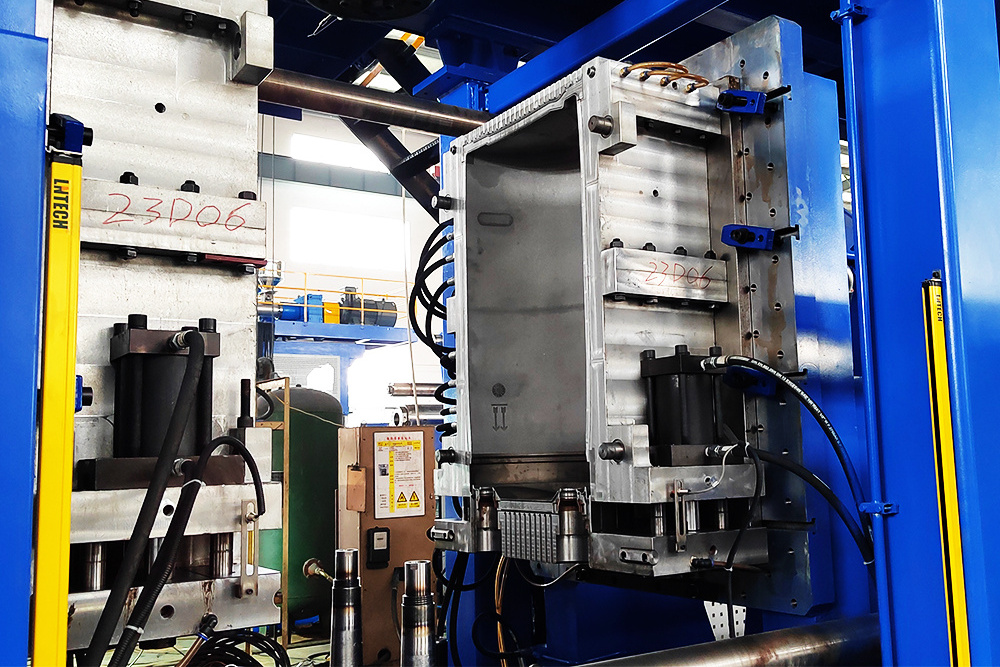

IBC tank mould

IBC tank moulds, crafted from premium cast aluminum, offer unparalleled precision and durability. Featuring customizable

inserts,they meet diverse engraving requirements with ease. Engineered for rapid cooling, these moulds ensure uniformity and efficiency,optimizing production cycles for enhanced productivity.The same IBC tote mold can produce 1200L,1000L,500L IBC tanks with different capacities according to customer requirements by extracting modules.

inserts,they meet diverse engraving requirements with ease. Engineered for rapid cooling, these moulds ensure uniformity and efficiency,optimizing production cycles for enhanced productivity.The same IBC tote mold can produce 1200L,1000L,500L IBC tanks with different capacities according to customer requirements by extracting modules.

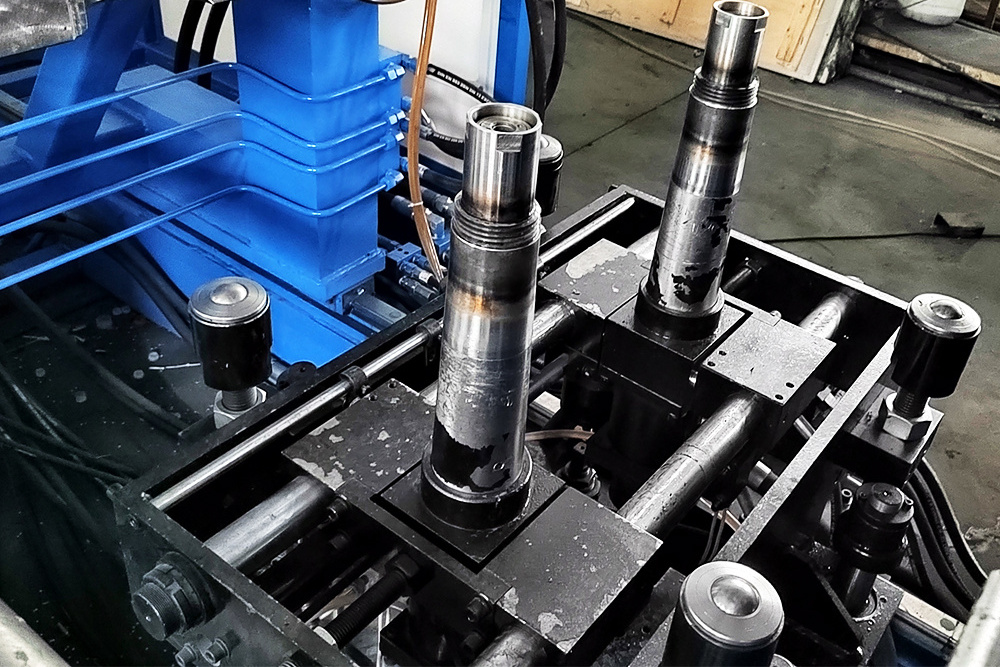

IBC screw

Single screw, twin screw, 3 screw with automatic feeding machine.

Drives plastic resin into the mold. Precision-crafted for optimal material flow and molding efficiency.

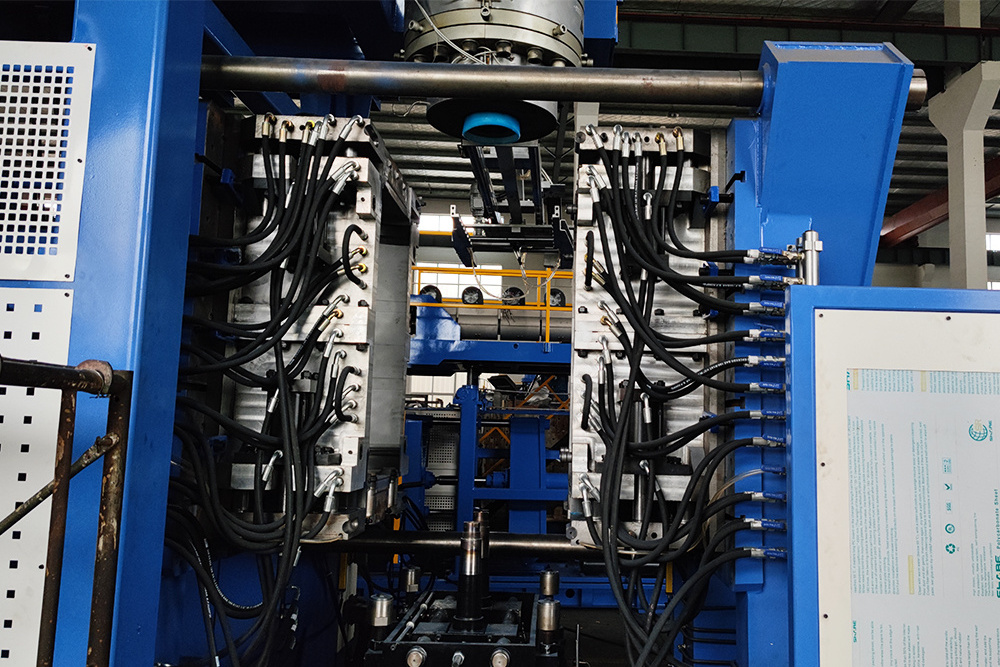

IBC die head

IBC machine's die head weighs 4ton, including die core, die sleeve, storage cylinder, precision design, uniform discharge.

IBC mould plate

Essential component for shaping IBC tanks.

The IBC mould plate is made of Q235A steel, which is quenched and tempered to make the mould plate harder.

IBC blow pin

The IBC blow pin is designed to move forward and backward through the guide rail to ensure the accurate position of the mouth of the IBC tank.

IBC Hydraulic System

IBC machine hydraulic system adopts international well-known brand Yuken

Ensures precise mold closure and product ejection for flawless IBC production.

IBC Electrical Box

IBC machine adopts Grefran control module and MOOG wall thickness control system

Safely regulates heating, cooling, and other functions for reliable performance.

IBC machine finished product

IBC tanks commonly known as ton-packed plastic container barrels, are standard names for intermediate bulk containers.

Itscomposition structure is divided into liner and frame. IBC containers can be reused many times, and the advantages reflected in filling, storage and transportation can significantly reduce costs. Compared with drums, IBC container can save 35% storage space.Its dimensions are in accordance with ISO standards, and are based on the principle of easy handling. Static empty drums can be stacked four high and transported in any conventional way.

Itscomposition structure is divided into liner and frame. IBC containers can be reused many times, and the advantages reflected in filling, storage and transportation can significantly reduce costs. Compared with drums, IBC container can save 35% storage space.Its dimensions are in accordance with ISO standards, and are based on the principle of easy handling. Static empty drums can be stacked four high and transported in any conventional way.

Hot Searches