- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

10ton

-

Design fuel:

-

Biomass Fired

-

Color:

-

Customer's Requirement

-

Material:

-

Thicker Stainless Steel

-

Thermal efficiency:

-

92%

-

Evaporation:

-

1ton/h

-

Keywords:

-

manual biomass boiler

-

Package:

-

Nude

-

Steam temperature:

-

≥184℃

-

Rated steam pressure:

-

1.0Mpa,1.25Mpa

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Xinda

-

Dimension(L*W*H):

-

4316*2200*2705mm

-

Weight:

-

10ton

-

Design fuel:

-

Biomass Fired

-

Color:

-

Customer's Requirement

-

Material:

-

Thicker Stainless Steel

-

Thermal efficiency:

-

92%

-

Evaporation:

-

1ton/h

-

Keywords:

-

manual biomass boiler

-

Package:

-

Nude

-

Steam temperature:

-

≥184℃

-

Rated steam pressure:

-

1.0Mpa,1.25Mpa

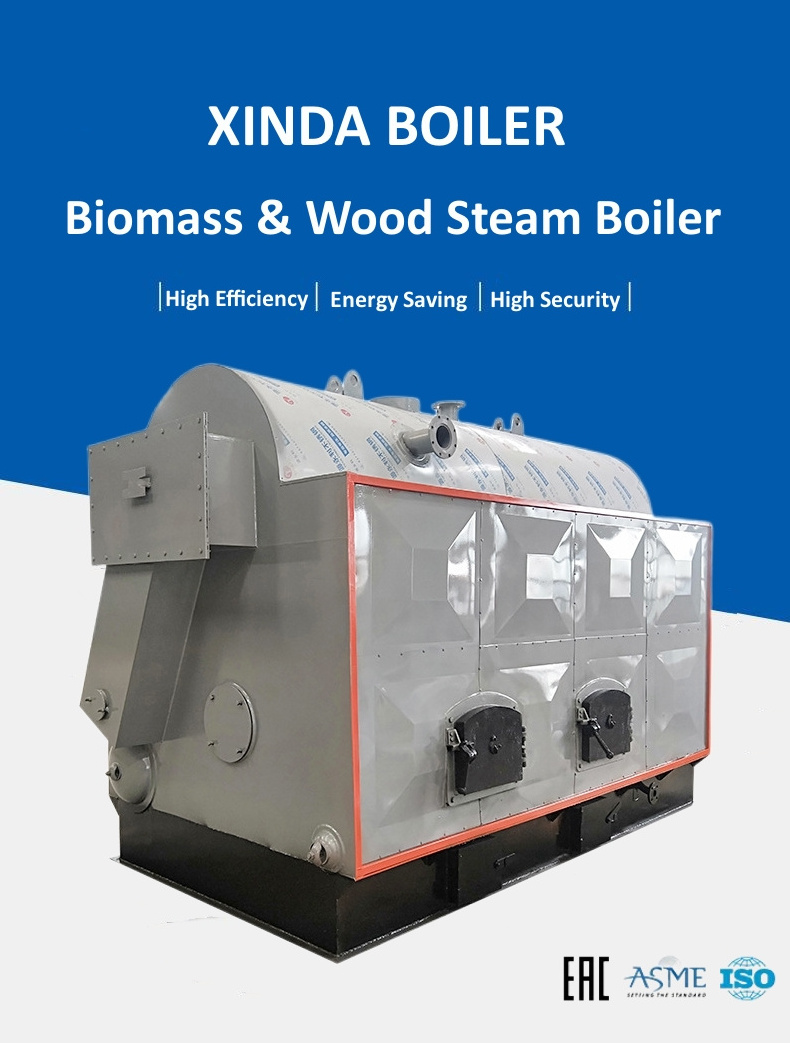

Products Description

Industrial DZH Series Horizontal Hand Moving Grate Coal Fuel Steam Boilers

Model:DZH Type Moving Grate Stoker Boiler

Structure:WaterTube Fire Tube Three Pass

Rated Steam Capacity:1-10 ton/hr

Rated Steam Pressure:0.7/1.0/1.25/1.6/2.5 Mpa

Rated Steam Temperature:170/184/194/204/225 C

Application:Textile Mill, Food & Beverage, Chemical, Rubber, Printing Plant, Paper Mill, Wood Processing

Model:DZH Type Moving Grate Stoker Boiler

Structure:WaterTube Fire Tube Three Pass

Rated Steam Capacity:1-10 ton/hr

Rated Steam Pressure:0.7/1.0/1.25/1.6/2.5 Mpa

Rated Steam Temperature:170/184/194/204/225 C

Application:Textile Mill, Food & Beverage, Chemical, Rubber, Printing Plant, Paper Mill, Wood Processing

Main feature of DZH series biomass steam boiler:

1. The boiler is a single-drum quick-installed three-pass water-fire tube boiler with large heating surface and high thermal efficiency;

2. The advantages of compact structure, reasonable water circulation design, and quick start-up;

3. The domestic advanced activity grate is adopted, which has good energy-saving effect and reduces the workload of installation and maintenance of the grate;

3. Reasonable air distribution in the grate is conducive to fuel burning and improving the efficiency of the whole machine

5. Reasonable air distribution is adopted to increase the effective area of the grate and increase the burning degree of the fuel;

6. The steam quality of the product is high, and the steam dryness is over 96%;

7. The product has multiple interlocking safety protection controls such as pressure, temperature, and water level;

8. The product control system is automatic, highly mechanized, simple and convenient to operate; the overall

quick-installation leaves the factory, and the installation is simple.

2. The advantages of compact structure, reasonable water circulation design, and quick start-up;

3. The domestic advanced activity grate is adopted, which has good energy-saving effect and reduces the workload of installation and maintenance of the grate;

3. Reasonable air distribution in the grate is conducive to fuel burning and improving the efficiency of the whole machine

5. Reasonable air distribution is adopted to increase the effective area of the grate and increase the burning degree of the fuel;

6. The steam quality of the product is high, and the steam dryness is over 96%;

7. The product has multiple interlocking safety protection controls such as pressure, temperature, and water level;

8. The product control system is automatic, highly mechanized, simple and convenient to operate; the overall

quick-installation leaves the factory, and the installation is simple.

Boiler advantage

Technical Parameters

|

Type

|

Rated capacity

|

Rated Pressure

|

Temperature

|

Design efficiency

|

|

|

t/h

|

MPa

|

℃

|

%

|

|

DZH0.5-1.0-All

|

0.5

|

1

|

170

|

80

|

|

DZH1-1.0-All

|

1

|

0.7

|

171

|

80

|

|

DZH2-1.0-All

|

2

|

1

|

184

|

80

|

|

DZH2-1.25-All

|

2

|

1.25

|

194

|

80

|

|

DZH4-1.25-All

|

4

|

1.25

|

194

|

80

|

|

DZH4-1.6-All

|

4

|

1.6

|

201

|

80

|

Fuel

Product packaging

Customer Evaluation

Company profile

Certificate

Hot Searches