* Versatile. Best suitable for access or formwork support.

* Timely tested and Proven design with safety accessories. Cuplock System has a proven performance history on an extensive number of sites, meeting the requirements of the various statutory bodies.

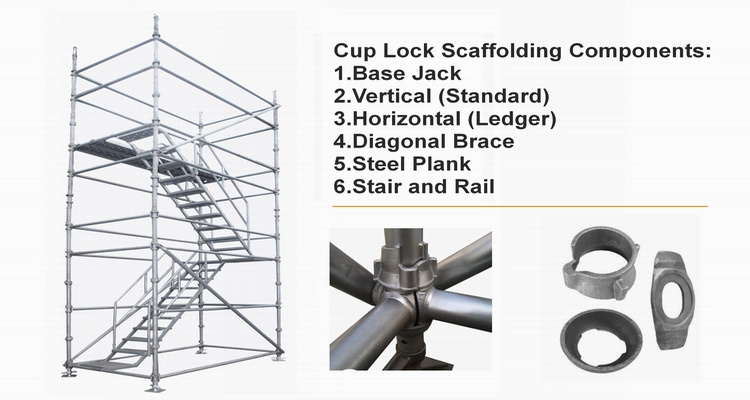

* Quick fastening of horizontals. Only 4 horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid.

* Quick/Fast/Solid erection and dismantling results in time and labour saving.

* Widely and Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved.

* Lightweight but high loads carrying capacity.

* Low maintenance.

The Main Components of Cup Lock Scaffolding