- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3m

-

Weight:

-

8 kg

-

Feeding width:

-

1220mm

-

Product name:

-

standing Beam roof panel Roll Forming Machine

-

Advantages:

-

High Efficent

-

Raw material:

-

PPGI/Aluminium/Galvanized Coil/Sheet

-

Color:

-

Requirement

-

Application:

-

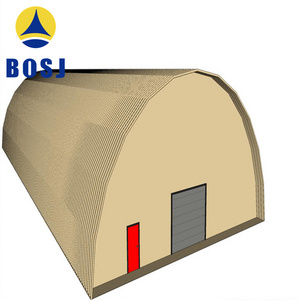

all construction work

-

Usage:

-

Producing roof panel for building houses/factories

-

Certification:

-

ISO; CE

-

Capacity:

-

100 sets/ year

-

Package:

-

nude packing with waterproof cover

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

10-15m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

XINBO

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

8*1.2*1.3m

-

Weight:

-

8 kg

-

Feeding width:

-

1220mm

-

Product name:

-

standing Beam roof panel Roll Forming Machine

-

Advantages:

-

High Efficent

-

Raw material:

-

PPGI/Aluminium/Galvanized Coil/Sheet

-

Color:

-

Requirement

-

Application:

-

all construction work

-

Usage:

-

Producing roof panel for building houses/factories

-

Certification:

-

ISO; CE

-

Capacity:

-

100 sets/ year

-

Package:

-

nude packing with waterproof cover

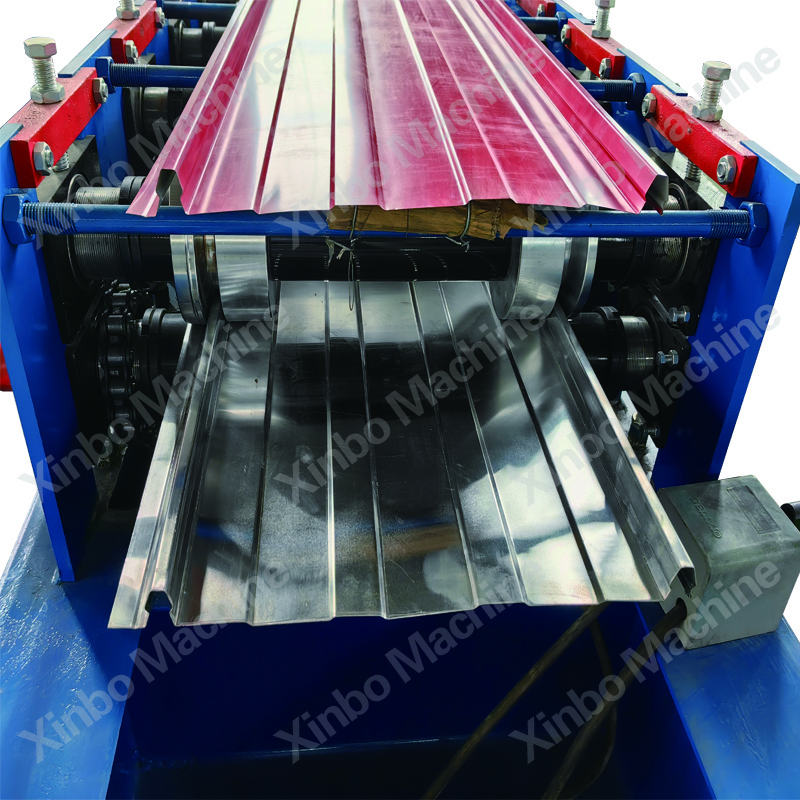

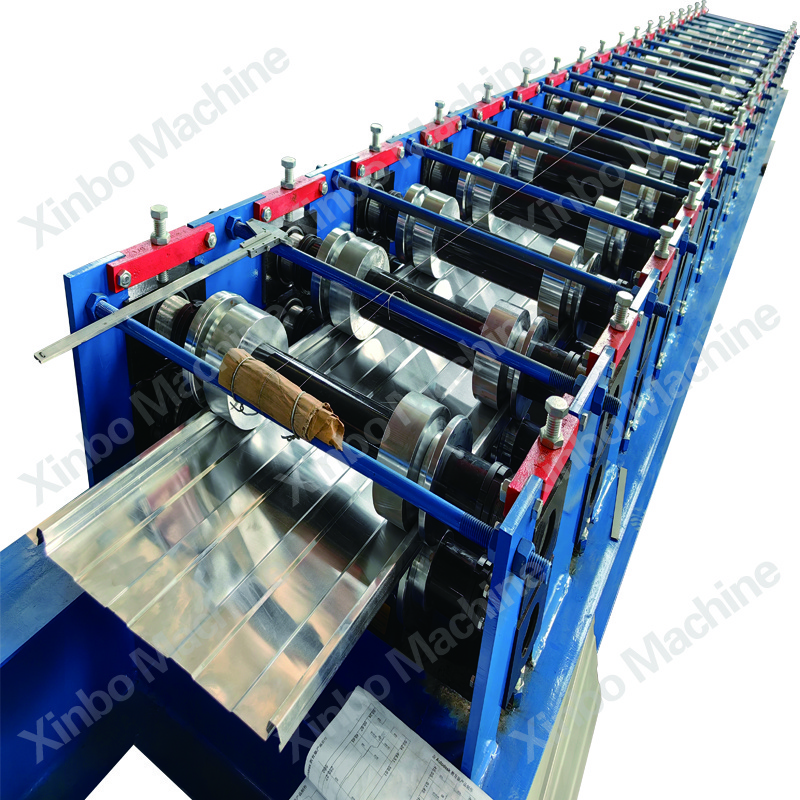

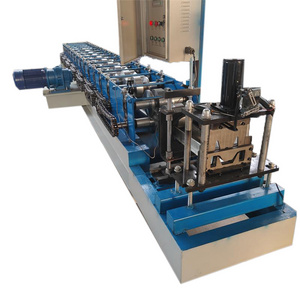

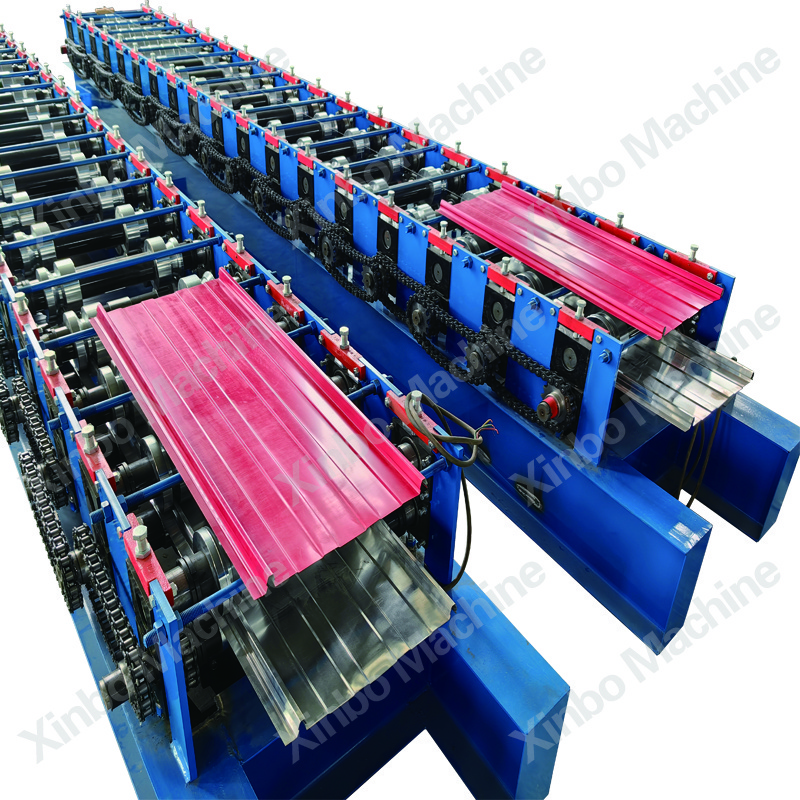

Automatic Color Steel 490 Self Lock Standing Seam Roof Sheet Roll Forming Machine

Portable Standing Beam roof panel metal roof roll forming machine in India

XINBO

Machine introduction:

Main features of standing beam roof panel roll forming machine

The advantages of standing beam roof panel roll forming machine are as follows:

1.Low cost, light weight but high strength, short building period, and re-cycle use

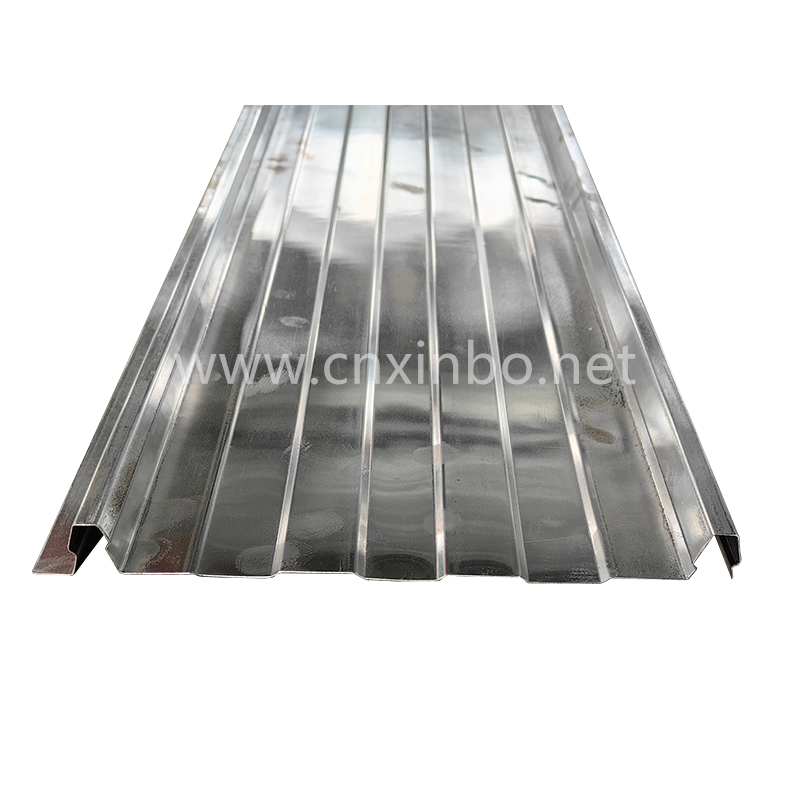

2.can produce KALZIP,LYSAGHT,BEMO,KINGSPAN style Standing Seam Roof Panel

3.Easy operation, low maintenance cost

1.Low cost, light weight but high strength, short building period, and re-cycle use

2.can produce KALZIP,LYSAGHT,BEMO,KINGSPAN style Standing Seam Roof Panel

3.Easy operation, low maintenance cost

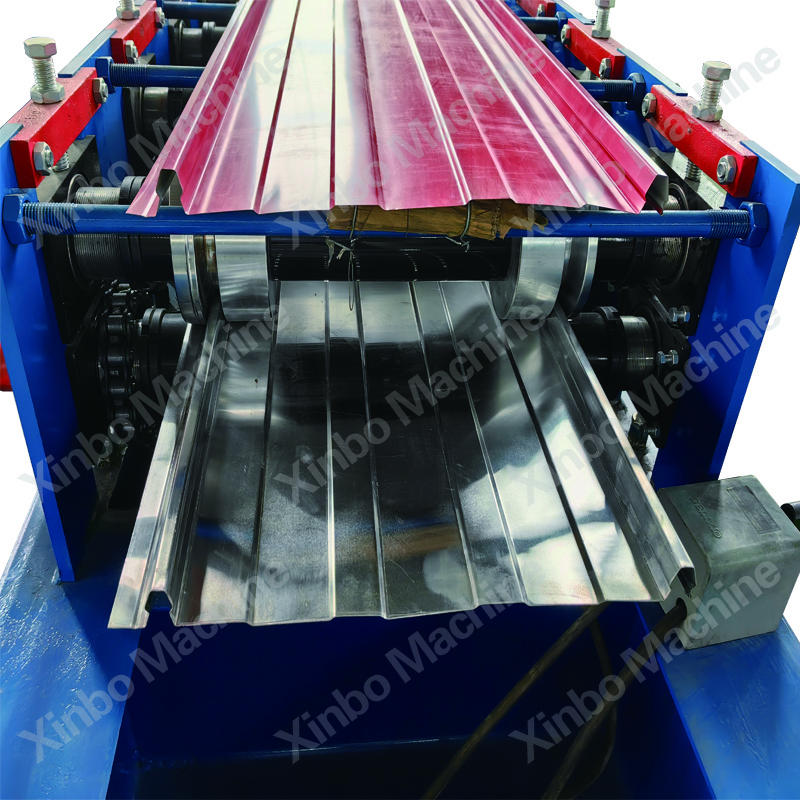

Processing Flow:

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving table

|

Suitable to Process

|

Color steel sheet ; Galvanized sheet ; Iron sheet; Aluminum sheet

|

|

Width of raw material

|

customized

|

|

Rollers

|

customized

|

|

Dimensions

|

About 6500*1550*1200mm

|

|

Power

|

3+3kw

|

|

Thickness of sheet

|

0.3-0.8mm as usual;

|

|

Material of cutting blade

|

Cr12

|

|

Diameter of the roller

|

customized

|

|

Voltage

|

380V, 50Hz, 3 phrases; or as customer needing

|

|

weight

|

About 3T

|

|

Productivity

|

10-15m/min

|

|

Control system

|

Automatically controlled by computer

|

Certification

Hot Searches