- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Oil drilling

-

Brand Name:

-

BaiYun

-

Model Number:

-

BY-Molecular Sieve

-

Product name:

-

Cms Carbon Molecular Sieve

-

Application:

-

Industrial Gas Production

-

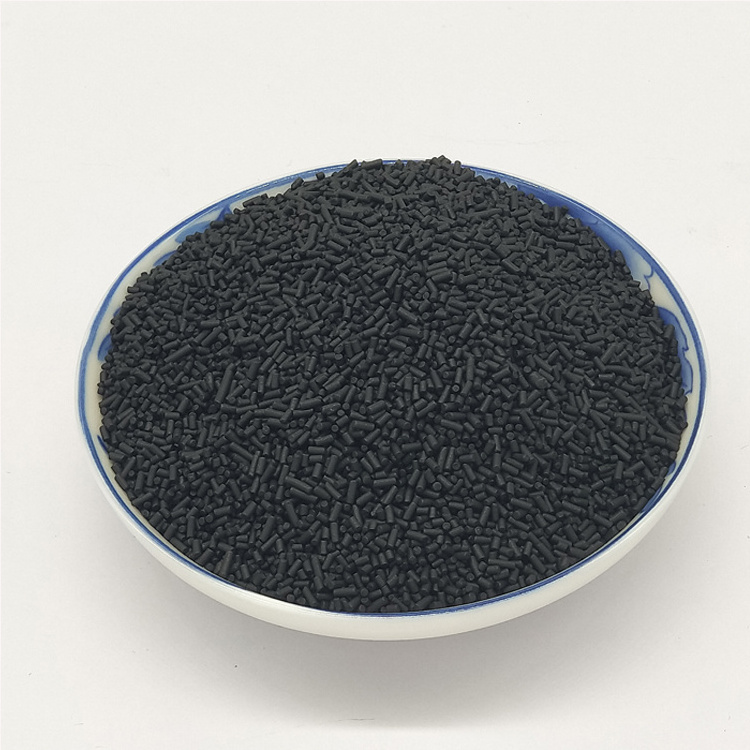

Appearance:

-

Sphere, Pellet, Ball

-

Keywords1:

-

Carbon Molecular Sieve in Black

-

Keyword 2:

-

Cms220 Carbon Molecular Sieves

-

Color:

-

Balck

-

Package:

-

150kg Steel Drum, 25kg Steel Drum, 25kg Carton Box

Quick Details

-

CAS No.:

-

7440-44-0

-

EINECS No.:

-

231-153-3

-

Place of Origin:

-

China

-

Type:

-

Oil drilling

-

Brand Name:

-

BaiYun

-

Model Number:

-

BY-Molecular Sieve

-

Product name:

-

Cms Carbon Molecular Sieve

-

Application:

-

Industrial Gas Production

-

Appearance:

-

Sphere, Pellet, Ball

-

Keywords1:

-

Carbon Molecular Sieve in Black

-

Keyword 2:

-

Cms220 Carbon Molecular Sieves

-

Color:

-

Balck

-

Package:

-

150kg Steel Drum, 25kg Steel Drum, 25kg Carton Box

Product description

The Carbon molecular sieve is a material containing tiny pores of a precise and uniform size that is used as an adsorbent for gases. When the pressure is high enough, the oxygen molecules, which pass through the pores of CMS much faster than the nitrogen molecules, are adsorbed, while the coming out nitrogen molecules will be enriched in gas phase. The enriched oxygen air, adsorbed by the CMS, will be released by reducing the pressure. Then the CMS is regenerated and ready for another cycle of producing nitrogen enriched air.

Physical properties

Diameter of the CMS granule: 1.5mm

Period of adsorption: 120S

Bulk density: 640-660g/L

Compressive strength: ≥100N/ granule

Application

1.Be used to separate air into N 2 and O 2 .

2.Be applied in petroleum chemical, heat treatment,electronic and food preservation industries.

Specification

| Model | Carbon Molecular Sieve | |||

| Shape | Pellet | |||

| Diameter | 1.2mm or customized | |||

| Crushing strength Min. | 50N/PC (The test temperature≤20ºC) | |||

| Bulk density | 660-700g/L (The test temperature≤20ºC) | |||

| Adsorbent time | 2*60s (The test temperature≤20ºC) | |||

| Type | Adsorbent pressure (MPa) | N2 purity (%) | N2 quantity (M3/MT.HT) | N2/Air (%) |

| CMS-200 | 0.75-0.8 | 99 | 225 | 2.41 |

| 99.5 | 200 | 2.6 | ||

| 99.9 | 110 | 3.9 | ||

| 99.99 | 70 | 4.8 | ||

| 99.999 | 40 | 7.0 | ||

| CMS-220 | 0.75-0.8 | 99 | 245 | 2.38 |

| 99.5 | 220 | 2.55 | ||

| 99.9 | 140 | 3.7 | ||

| 99.99 | 100 | 4.7 | ||

| 99.999 | 55 | 6.8 | ||

| CMS-240 | 0.75-0.8 | 99 | 260 | 2.35 |

| 99.5 | 240 | 2.5 | ||

| 99.9 | 155 | 3.5 | ||

| 99.99 | 110 | 4.65 | ||

| 99.999 | 65 | 6.7 | ||

| CMS-260 | 0.75-0.8 | 99 | 320 | 2.2 |

| 99.5 | 260 | 2.5 | ||

| 99.9 | 175 | 3.5 | ||

| 99.99 | 120 | 4.6 | ||

| 99.999 | ||||

Hand & Storage Recommendation

Molecular Sieve should be handled to avoid generation of dusty conditions at the workplace. Storage in a dry

warehouse is recommended. Open packages should be resealed to prevent contamination and

adsorption of water or other gases and vapors. The material in bag-in-box should be used within 12

months,while bag-in-steel drum should be used within 24 months.

Regeneration

To achieve good operating performance and long life as much as possible, after a certain period of time use must be regenerated .

After correct molecular sieve regeneration , make it get the low attenuation of mechanical properties and adsorption

There are two basic approaches:

- Temperature variation .

Generally used in the preheating gas heating, purge molecular sieve to about 200 º C, and stripping down the adsorbate .

- Variable pressure .

Usually used in the gas phase adsorption process.Maintain a constant temperature adsorbent and by reducing

pressure and backing purge inert gas , to remove the adsorbate.