- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZK

-

Model Number:

-

1200*2400-2900*4700

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

11.2-81T

-

Warranty:

-

3 years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feeding Size:

-

25mm

-

Output Size:

-

0.074-0.4mm

-

Speed:

-

30 r/min Max

-

Installation:

-

Under our engineer's guide

-

Color:

-

Customized

-

Application:

-

Coal Power Plant

-

Spare parts supplying:

-

Paid

-

After sale service:

-

Engineer Avalable

-

Product name:

-

Micron Fine Grinding Mill

-

Certificate:

-

ISO

-

Certification:

-

ISO,CE

Quick Details

-

Power:

-

45-570KW

-

Capacity(t/h):

-

1.4-16TPH

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Model Number:

-

1200*2400-2900*4700

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

11.2-81T

-

Warranty:

-

3 years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Feeding Size:

-

25mm

-

Output Size:

-

0.074-0.4mm

-

Speed:

-

30 r/min Max

-

Installation:

-

Under our engineer's guide

-

Color:

-

Customized

-

Application:

-

Coal Power Plant

-

Spare parts supplying:

-

Paid

-

After sale service:

-

Engineer Avalable

-

Product name:

-

Micron Fine Grinding Mill

-

Certificate:

-

ISO

-

Certification:

-

ISO,CE

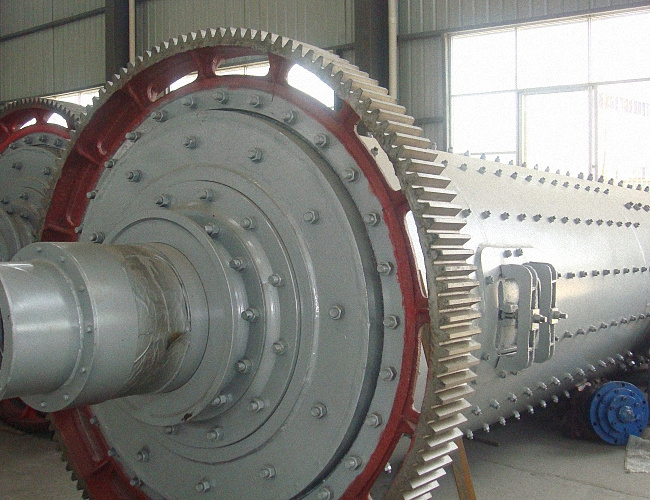

High Efficiency Air Swept Coal Mill/Coal Pulverizer/Vertical Coal Mill

1. Introduction of Coal Mill

Coal mill is used for coal grinding system for industrial furnace and rotary kiln which required the fineness of pulverized coal being 200 mesh (85%) and the water content being less than 2%. Air swept coal mill is the best processing equipment for grinding and drying coal powder at the same time.

2. Types of Coal Mill

Horizontal Coal Mill

Vertical Coal Mill

2.Working Principle of Coal mill

Coal is fed by feeding equipment into the ground inside of the coal mill , hot air into duct into the ground from within, as the rotation of the cylinder grinding machine, hot air in grinding coal and coal in grinding heat within, shattered and grinding, in the meanwhile, by grinding coal powder was through the hot air, via within grinding of mill discharging device brought out the grinding machine.

3.Technical Parameters of Coal Mill

|

Specification (mm) |

Grinding media loading |

Cylinder rev(r/min) |

Capacity (t/h) |

Motor |

||

|

Model |

Power(kw) |

Voltage(v) |

||||

|

Φ1200x2400 |

4.8 |

32 |

1.4-2 |

Y280M-8 |

45 |

380 |

|

Φ1500x3000 |

8 |

28.8 |

2-3 |

JR125-8 |

95 |

380 |

|

Φ1700x2500 |

7.5 |

24.5 |

3-5 |

JR116-6 |

95 |

380 |

|

Φ2200x3000 |

13 |

22 |

5-6 |

JR136-8 |

180 |

380 |

|

Φ2200x4400 |

|

21 |

8-9 |

YRKK4501-6 |

250 |

380 |

|

Φ2200x5800 |

|

21 |

5.5-7 |

Y4005-8 |

280 |

380 |

|

Φ2400x4750 |

22 |

20 |

10-12 |

YR400-8 |

280 |

6000 |

|

Φ2400x4000+2000 |

|

|

10-11 |

YRKK450-8 |

250 |

6000 |

|

Φ2400x4500+2000 |

|

|

10-12 |

YRKK500-8 |

280 |

6000 |

|

Φ2500x3900 |

|

|

14 |

JR138-8 |

280 |

6000 |

|

Φ2600x(5250+2250) |

|

|

9-10 |

YRKK500-8 |

400 |

6000 |

|

Φ2800x(5000+3000) |

|

|

13-13.5 |

Y5001-8 |

500 |

6000 |

|

Φ2900x4700 |

35 |

18.3 |

16 |

JSQ1512-6 |

570 |

6000 |

4. Features and Benefits of C oal Mill

- Good for grinding and drying coal

- Grinding coal to the size of 200 mesh

- High quality and low consumption

Pre-sale Service

- Determine your needs and expectations through positive communication, active advice, and visit arrangement;

- Provide you with necessary preliminary design information, bidding documents or quotation sheet based on your needs and expectations;

- Provide you with technical solutions and help you determine;

- Provide you with draft contract and technology agreements;

- Meet requirements and needs of your bidding documents or other means;

- Other services before signing contract;

- Contract evaluation and contract signing.

After-sale Service

- Select excellent installation team or installation service personnel for you;

- Provide you with operating and training services;

- Help with the equipment commissioning, and solve problems in trial operation;

- Check and acceptance service for single equipment or a whole production line;

- Service items including follow-up visit, customer satisfaction surveys and so on;

- Timely provide you with necessary accessories after acceptance;

- Provide you with warranty services of repair, replacement and refund if conditions are fulfilled.

- Help you solve other problems.