It can be 4-axis linkage, running faster and more smoothly, and can also achieve jog movement. The motor increases the encoder closed-loop drive to overcome the problem of out of step and escort the placement.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CHM-T36VA

-

Product name:

-

Place Machine\ LED Mounter\LED Assembly Machine

-

Brand:

-

charmhigh

-

Model:

-

CHM-T36VA

-

PCB size:

-

10mm(L)x10mm(W)~345mm(L)x360mm(W)

-

mounting head quantity:

-

2

-

control accuracy:

-

0.025mm

-

Component Type:

-

0402/0603~5050/SOT/SOP/QFP/QFN/BGA

-

Mounting Speed:

-

6000cph (optimal without vision detection)

-

Control System:

-

External computer required (Windows)

-

Feeding System:

-

29 tape feeding stacks

Quick Details

-

Weight (KG):

-

39

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

charmhigh

-

Model Number:

-

CHM-T36VA

-

Product name:

-

Place Machine\ LED Mounter\LED Assembly Machine

-

Brand:

-

charmhigh

-

Model:

-

CHM-T36VA

-

PCB size:

-

10mm(L)x10mm(W)~345mm(L)x360mm(W)

-

mounting head quantity:

-

2

-

control accuracy:

-

0.025mm

-

Component Type:

-

0402/0603~5050/SOT/SOP/QFP/QFN/BGA

-

Mounting Speed:

-

6000cph (optimal without vision detection)

-

Control System:

-

External computer required (Windows)

-

Feeding System:

-

29 tape feeding stacks

Specification

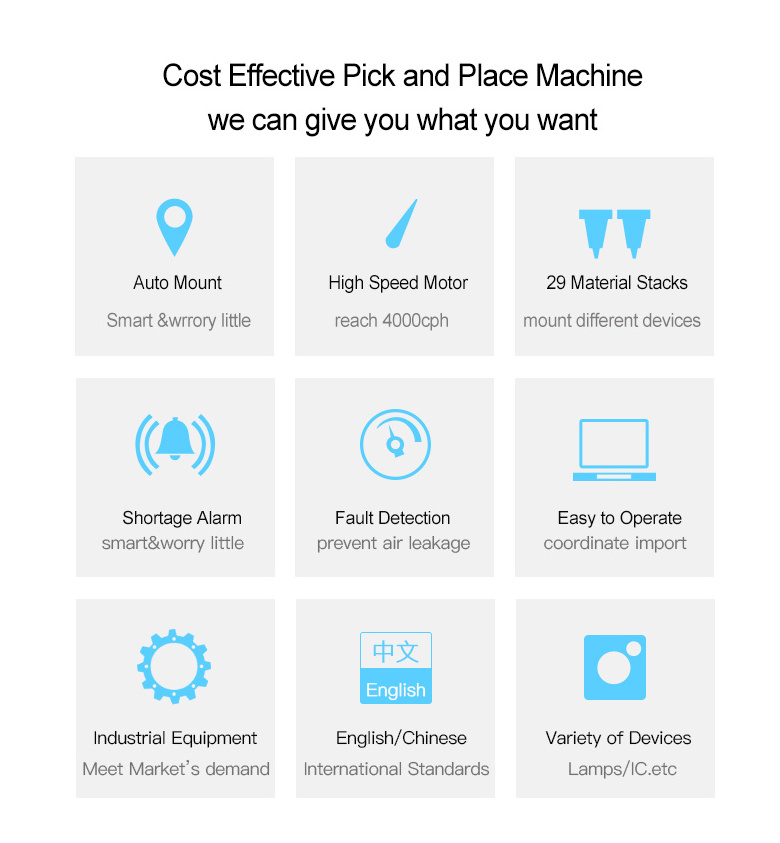

CHM-T36VA Desktop Pick And Place Machine Feature

1. Closed-loop control, Step motor with the encoder.

2. Pcb size: Max:

345mm(L)×360mm(W)

(without tray).

3.

External computer required (Windows),

4.

With vision system.The smallest component can be attached 0402. The largest: 22x22mm.

5.

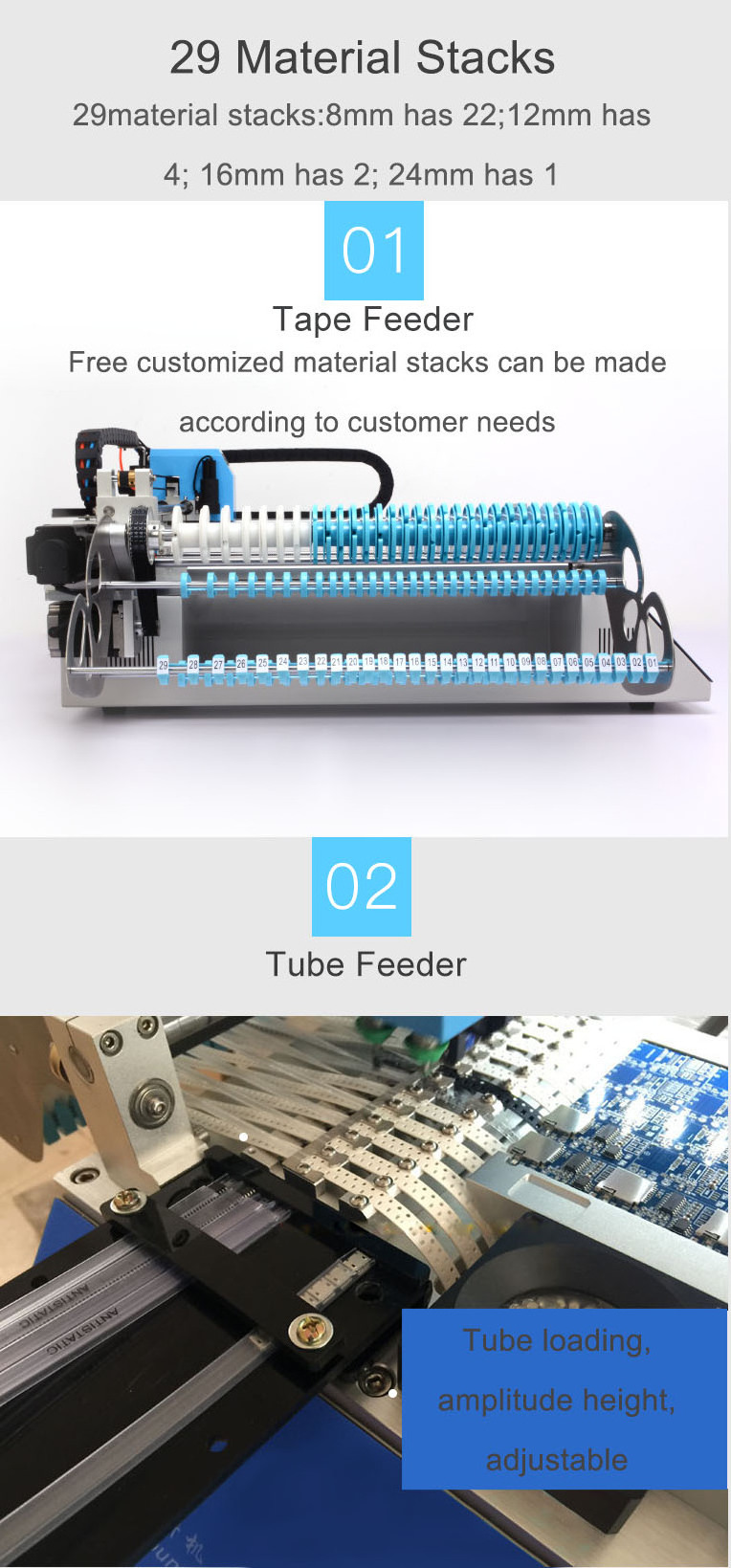

Feeding System:29 tape feeding stacks (8mm:22,12mm:4,16mm:2,24mm:1;)

6. With HD CCD Camera, accuracyand quick.

6. With HD CCD Camera, accuracyand quick.

7.

With 2 pick and place heads

8.

Independent research and development system.

Permanently enjoy free software upgrade service.

9.

One year warranty

|

Specification

|

|

|

|

Dimensions

|

940mm(L)×710mm(W)×340mm(H)

|

|

|

Weight

|

39kg

|

|

|

Power Supply

|

AC220V (50Hz, single phase) /AC110V (60Hz, single phase);

300W |

|

|

Air Supply

|

No external air supply required

|

|

|

Vacuum Generation

|

Built-in vacuum pump

|

|

|

Mounting Head Quantity

|

2

|

|

|

Mounting Speed

|

6000cph(optimalwithout vision detection);

2500cph (optimal with vision detection) |

|

|

Control Accuracy

|

0.025mm

|

|

|

Component Type

|

0402/0603~5050/SOT/SOP/QFP/QFN/BGA, etc.

(resistor/capacitor/diode/triode/LED/IC, etc.) |

|

|

PCB Thickness

|

0.6mm~3.5mm

|

|

|

PCB Size

|

10mm(L)×10mm(W)~345mm(L)×360mm(W)

|

|

|

PCB Conveying

|

Manual operation

|

|

|

Nozzle Change

|

Manual operation

|

|

|

Control System

|

External computer required (Windows)

|

|

|

|

X&Y-axis driven by stepping motors in the way of closed-loop control realized by encoder; Z-axis capable of reset detection;all motors adopting flexible S-curve

acceleration and deceleration; tape puller automatic reset supported

|

|

|

Transmission System

|

Synchronous belt+polished rod

|

|

|

|

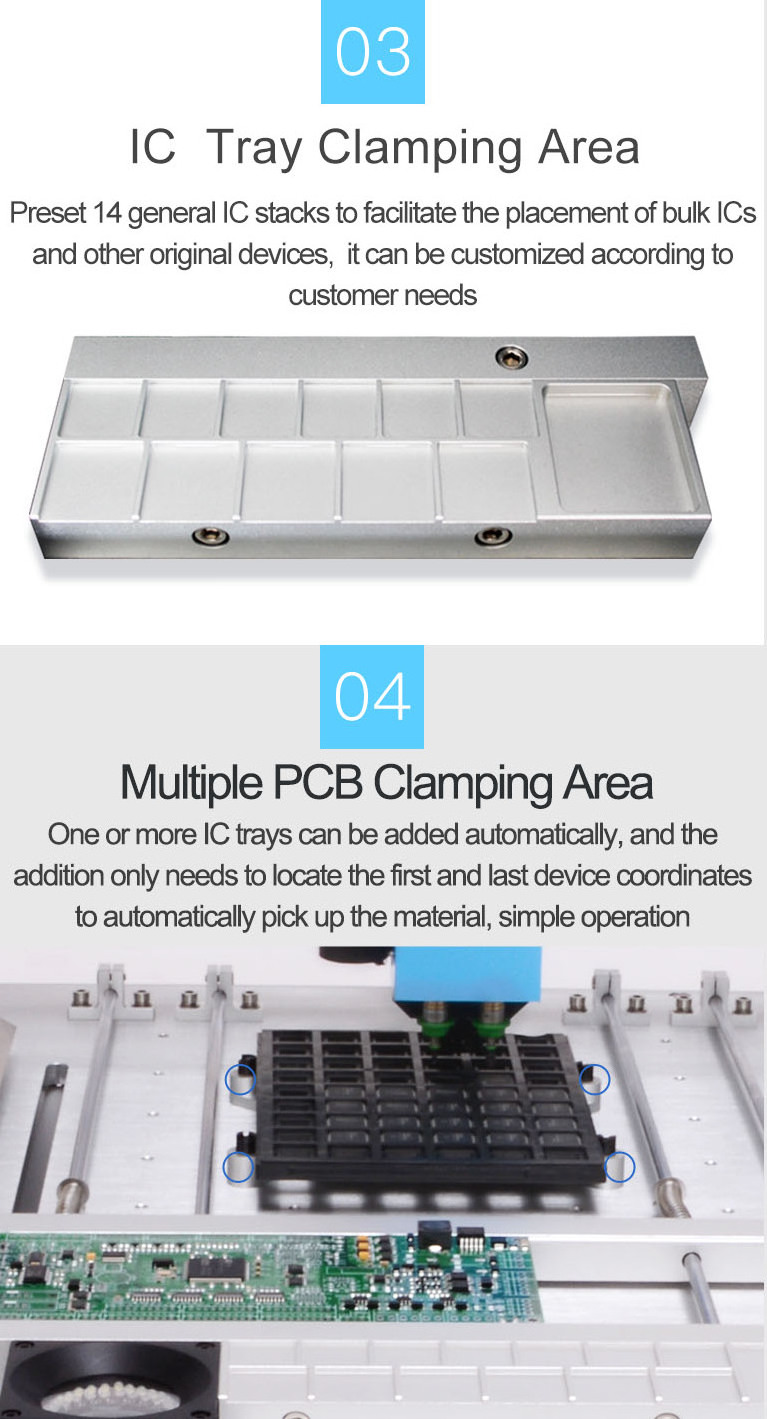

29 tape feeding stacks(8mm:22,12mm:4,16mm:2,24mm:1;customization supported), 14 preset general IC stacks, work surface custom IC trays and stick feeder supported

|

|

|

|

Up-looking camara for component automatic calibration (component size applicable: 22mm×22mm); down-looking camera for PCB calibration via Mark Point and component positioning

|

|

Description

Dual vision calibration, automatic correction

It can accurately mount IC devices, automatically correct the picking error, and use industrial high-precision CCD to collect IC pins, which makes the calculation more accurate and ensures the placement accuracy.

PCB Clamping Area

Max support PCB 345mm(L)x360mm(W), Suitable for various process mounting

Stepping Closed Loop Motor

Operating System

Placement Effect

Favorable Reviews

Packing & Delivery

To better ens

ure t

he safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Certificates & Clients

Factory Condition

FAQ

Q How about the warranty?

A: One year warranty for whole machine and free of charge for spare parts within the warranty period.Free On-line technical support for permanent.

Q Is it easy to operate?

A: Yes.It’s simple and easy to operate.. We provide English manual and guide video to show you how to use and We assure our timely support until you can control the machine.

Q.Payment Term?

A:We accept:T/T, VISA, PAYPAL, WEST UNION, BANK TRANSFER, ONLINE BANK PAYMENT.

Q:How about the quality certificate?

A: We havepassed CE certificate, ISO9001(IQNET) and have own patent.

Q: Which language is the software? Do you provide software updates?

A:English or Chinese. Free to upgrade software for lifetime.

Q Is it easy to operate?

A: Yes.It’s simple and easy to operate.. We provide English manual and guide video to show you how to use and We assure our timely support until you can control the machine.

Q.Payment Term?

A:We accept:T/T, VISA, PAYPAL, WEST UNION, BANK TRANSFER, ONLINE BANK PAYMENT.

Q:How about the quality certificate?

A: We havepassed CE certificate, ISO9001(IQNET) and have own patent.

Q: Which language is the software? Do you provide software updates?

A:English or Chinese. Free to upgrade software for lifetime.

Hot Searches