◎High electro-optical conversion efficiency

◎Strong anti-high anti-reaction ability

◎More stable beam quality

◎Maintenance-free operation

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Yosoon

-

Single Pulse Energy:

-

100

-

Pulse Width:

-

100

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

30

-

Dimensions:

-

1.35CBM3

-

Weight (KG):

-

200 KG

-

Warranty of core components:

-

laser source 2 years, chiller and head 1 Year

-

Core Components:

-

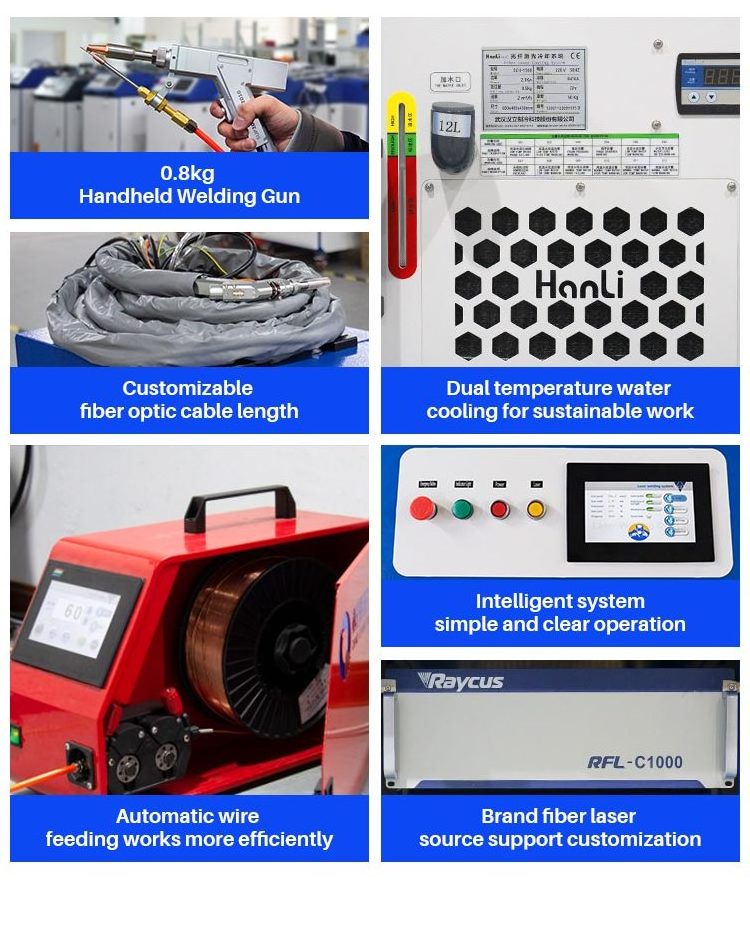

Max/Raycus laser source, HanLi water coolor, laser head

-

Product name:

-

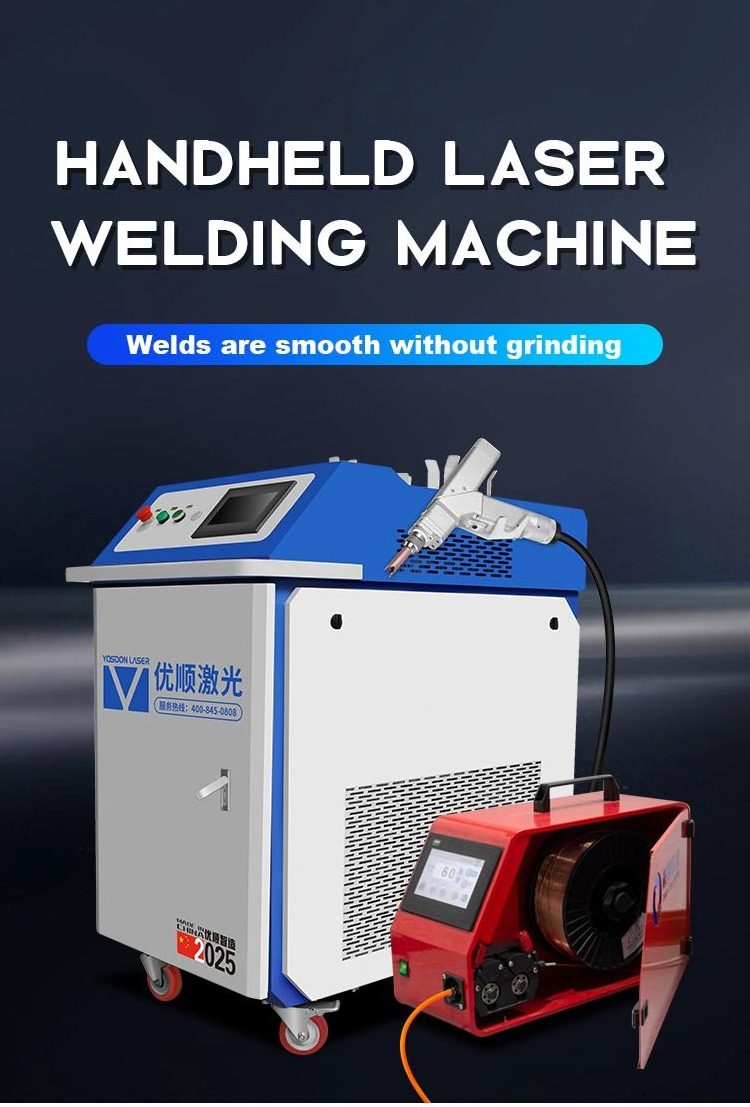

Handheld Laser Welding Machine

-

Laser source:

-

Max/Raycus/yosoon

-

Laser Power:

-

1000w/1500W/2000W/3000w

-

Applicable Material:

-

Metal Materials

-

Laser wavelength:

-

1064nm

-

Application material:

-

Metal Stainless Steel Aluminum

-

Application:

-

Metal Stainless Steel Laser Welder

-

Cooling System:

-

Water Cooling

-

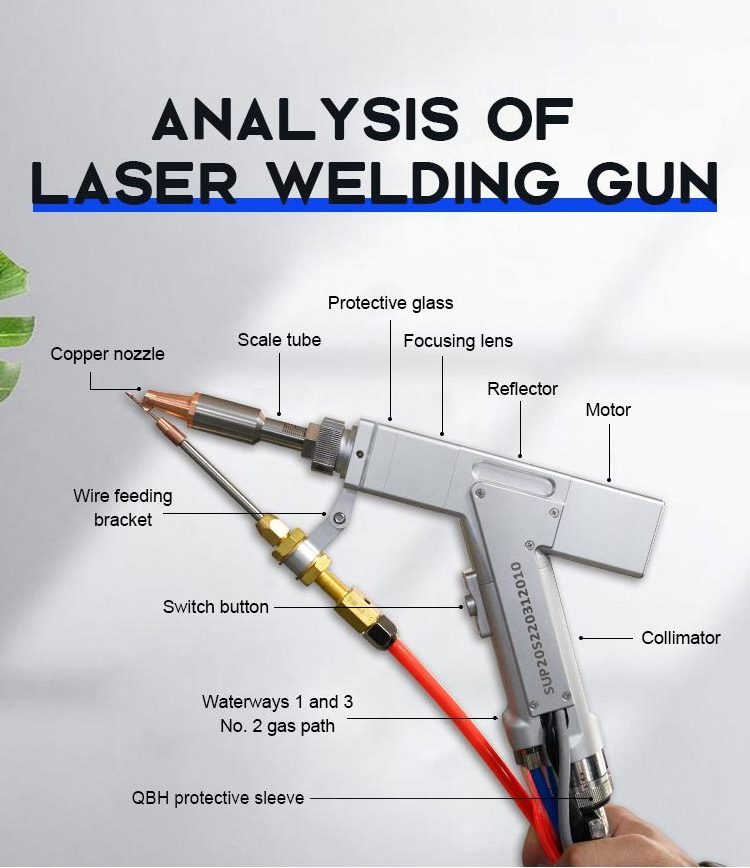

Welding head:

-

Ospri /sup/yosoon

-

Welding materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Welding Machine )

Quick Details

-

Max. Output Power:

-

1000W/1500W/2000W/3000w

-

Usage:

-

fiber laser welding

-

Laser Source Brand:

-

RAYCUS/Max/yosoon

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Yosoon

-

Single Pulse Energy:

-

100

-

Pulse Width:

-

100

-

Wavelength:

-

1064nm

-

Focal Spot Diameter:

-

30

-

Dimensions:

-

1.35CBM3

-

Weight (KG):

-

200 KG

-

Warranty of core components:

-

laser source 2 years, chiller and head 1 Year

-

Core Components:

-

Max/Raycus laser source, HanLi water coolor, laser head

-

Product name:

-

Handheld Laser Welding Machine

-

Laser source:

-

Max/Raycus/yosoon

-

Laser Power:

-

1000w/1500W/2000W/3000w

-

Applicable Material:

-

Metal Materials

-

Laser wavelength:

-

1064nm

-

Application material:

-

Metal Stainless Steel Aluminum

-

Application:

-

Metal Stainless Steel Laser Welder

-

Cooling System:

-

Water Cooling

-

Welding head:

-

Ospri /sup/yosoon

-

Welding materials:

-

Stainless Steel Carbon Steel Etc( Metal Laser Welding Machine )

Stainless steel Aluminum carbon metal

Welding Machine

1500w 2000W 1000W 3kw handheld laser machine price

Welding machine

working principle

Laser welding uses high-energy laser pulses to locally heat a material in a small area. The energy of laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool.

Laser welding uses high-energy laser pulses to locally heat a material in a small area. The energy of laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool.

Why need automatic wire feeding?

In actual welding, sometimes part fluctuations and fixture errors often cause various welding defects. After adding wire feed for welding, the laser beam is easy to guide and focus, which can realize welding of any complicated shape, with high degree of automation, fast welding speed, high production efficiency, and stable and reliable processing quality.

In actual welding, sometimes part fluctuations and fixture errors often cause various welding defects. After adding wire feed for welding, the laser beam is easy to guide and focus, which can realize welding of any complicated shape, with high degree of automation, fast welding speed, high production efficiency, and stable and reliable processing quality.

1.Swing welding head can be used for welding at any angle or shape. It can be used for 1000W/1500W/2000W power

2.Adjustable weld width (range 0-6mm)

3.Not request mature operate, fresh worker can also do

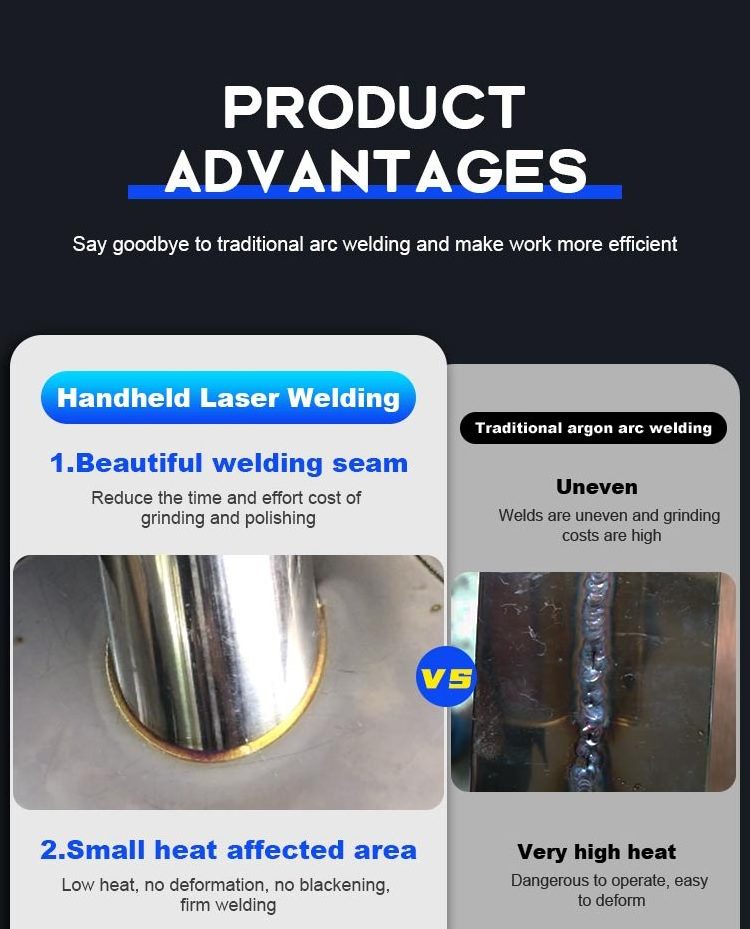

4.Smooth and beautiful, not deformation, not blackening, strong welding, no grinding required

5.Welding material: stainless steel, carbon steel and other metals

Product Paramenters

|

|

|

|

||||

|

Model

|

YSW-1000

|

YSW-1500

|

YSW-2000

|

|||

|

Laser source

|

Raycus(Optional)

|

Raycus(Optional)

|

Raycus(Optional)

|

|||

|

Laser power

|

1000W

|

1500W

|

2000W

|

|||

|

Welding gun

|

ChaoQiangWeiYe(Optional)

|

|

|

|||

|

Chiller

|

Hanli(Optional)

|

Hanli(Optional)

|

Hanli(Optional)

|

|||

|

Wire feeding device

|

Optional

|

Optional

|

Optional

|

|||

|

Machine

|

All-in-one

|

All-in-one

|

All-in-one

|

|||

|

Weight

|

280KG

|

280KG

|

280KG

|

|||

|

Dimension(mm)

|

1200L*700W*1350H

|

1200L*700W*1350H

|

1200L*700W*1350H

|

|||

|

Power supply

|

220V

|

220V

|

220V

|

|||

Product Details

◎Efficiency increased by 2-3 times

◎360°flexible movement

◎Swing welding head for easy operation

◎Fast welding speed

◎360°flexible movement

◎Swing welding head for easy operation

◎Fast welding speed

◎ Intelligent touch system, simple interface operation

◎ Just set the laser power, scan width&speed

◎ Up to 9 sets of technical data can be saved

◎ Spot and continuous welding modes

◎ Extensive selection of technologies, choose between zoom mode or gap mode in spot welding mode

◎ Chiller alarm, safety grounding, laser source and other multiple protection mechanism alarms

◎ Just set the laser power, scan width&speed

◎ Up to 9 sets of technical data can be saved

◎ Spot and continuous welding modes

◎ Extensive selection of technologies, choose between zoom mode or gap mode in spot welding mode

◎ Chiller alarm, safety grounding, laser source and other multiple protection mechanism alarms

◎ Manual feeding and pumping functions

◎ Upper and lower feeding wheel dual drive control

◎ Feed speed 38-600 cm/min

◎ Compatible with 5KG, 10KG, 15KG welding wire

◎ Upper and lower feeding wheel dual drive control

◎ Feed speed 38-600 cm/min

◎ Compatible with 5KG, 10KG, 15KG welding wire

Technical parameter:

◎ Laser source: 1000W-2000W

◎ Freezing medium: R410A

◎ Water tank volume: 16L

◎ Laser source: 1000W-2000W

◎ Freezing medium: R410A

◎ Water tank volume: 16L

Product Specification

|

Item

|

Data

|

|

|

||

|

Product size

|

1105L*720W*1005H mm

|

|

|

||

|

Laser power

|

1000W/15000W/2000W

|

|

|

||

|

Laser wavelength

|

1064nm

|

|

|

||

|

Laser Source Brand

|

IPG, SPI, Raycus, Max, JPT

|

|

|

||

|

Laser type

|

Fiber Laser

|

|

|

||

|

Welding depth

|

0-6mm

|

|

|

||

|

Cooling way

|

Water cooling

|

|

|

||

Product packaging

2. Pearl cotton and plastic wrap will be used to protect the machine from sea water and collision;

3. We use standard export fumigation wooden box, to keep machine security;

4. Machines will be uploaded into container in factory or at the departure Port;

Company profile

FAQ

1. What kind of laser machine and model should I choose?

You can tell us your processing size and detail requirements, so that we can recommend the most suitable model for you.

You can tell us your processing size and detail requirements, so that we can recommend the most suitable model for you.

2. What kind of materials does the laser machine can process?

We have different laser machines, such as Fiber laser, Co2 Laser, UV Laser,Green Laser.Normally Fiber laser can process metal and plastic. Co2 laser is for processing non metallic materials, such as Acrylic, PMMA, Wood, Glass. Leather,Jeans,Paper, Textiles Garments heat transfer vinyl and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

3. Is it easy to operate?

We will send you manual and guide vedio in English. Or we can talk by phone, email or other contact ways.

4. How will you do the after-sale service?

The machine has one year guarantee.Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

5. What is your equipment lead time?

Fiber laser cutting machine lead time is around 45 days.

Laser welding machine and laser marking machine delivery time is about 30 days.

6. How will you do the package and shipping?

All of our equipment are packed in export standard cases

Express, air shipping, sea shipping are all available.

We have different laser machines, such as Fiber laser, Co2 Laser, UV Laser,Green Laser.Normally Fiber laser can process metal and plastic. Co2 laser is for processing non metallic materials, such as Acrylic, PMMA, Wood, Glass. Leather,Jeans,Paper, Textiles Garments heat transfer vinyl and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass, crystal and some special processing job.

3. Is it easy to operate?

We will send you manual and guide vedio in English. Or we can talk by phone, email or other contact ways.

4. How will you do the after-sale service?

The machine has one year guarantee.Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

5. What is your equipment lead time?

Fiber laser cutting machine lead time is around 45 days.

Laser welding machine and laser marking machine delivery time is about 30 days.

6. How will you do the package and shipping?

All of our equipment are packed in export standard cases

Express, air shipping, sea shipping are all available.

7. What is the payment terms?

T/T, or part of L/C at sight for some special regions.

T/T, or part of L/C at sight for some special regions.

Hot Searches