- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Station

-

Model Number:

-

SA-600-01

-

Input voltage:

-

9-36V dc

-

System operating voltage:

-

DC24v

-

Ambient temperature range of level gauge:

-

-25~55°

-

Relative humidity:

-

45-75%

-

Atmospheric pressure:

-

86KPa to 106KPa

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 years

-

Place of Origin:

-

China

-

Brand Name:

-

Station

-

Model Number:

-

SA-600-01

-

Input voltage:

-

9-36V dc

-

System operating voltage:

-

DC24v

-

Ambient temperature range of level gauge:

-

-25~55°

-

Relative humidity:

-

45-75%

-

Atmospheric pressure:

-

86KPa to 106KPa

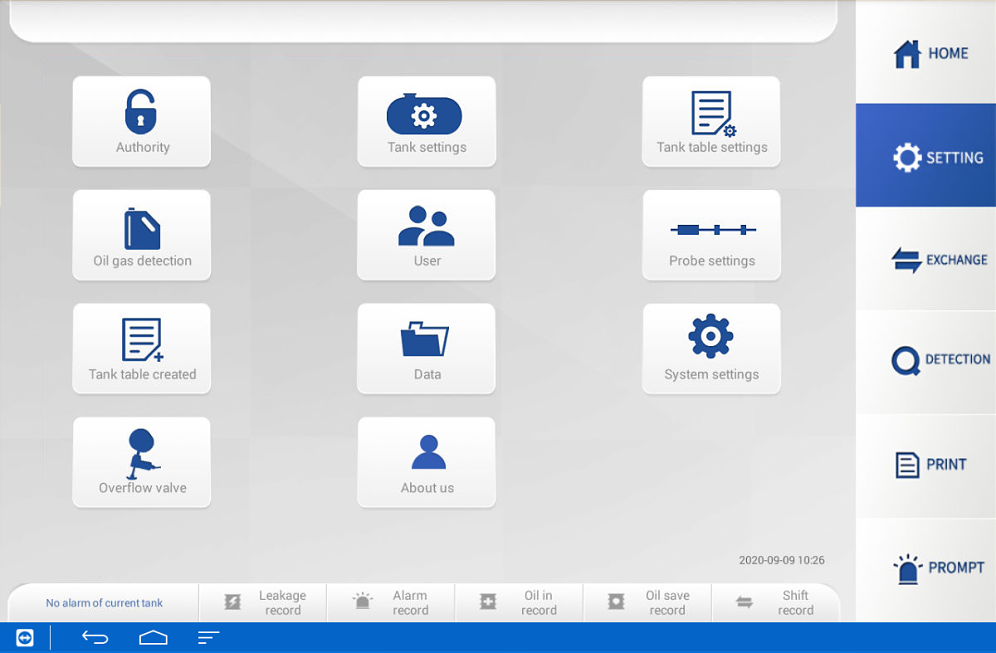

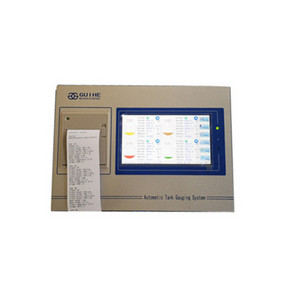

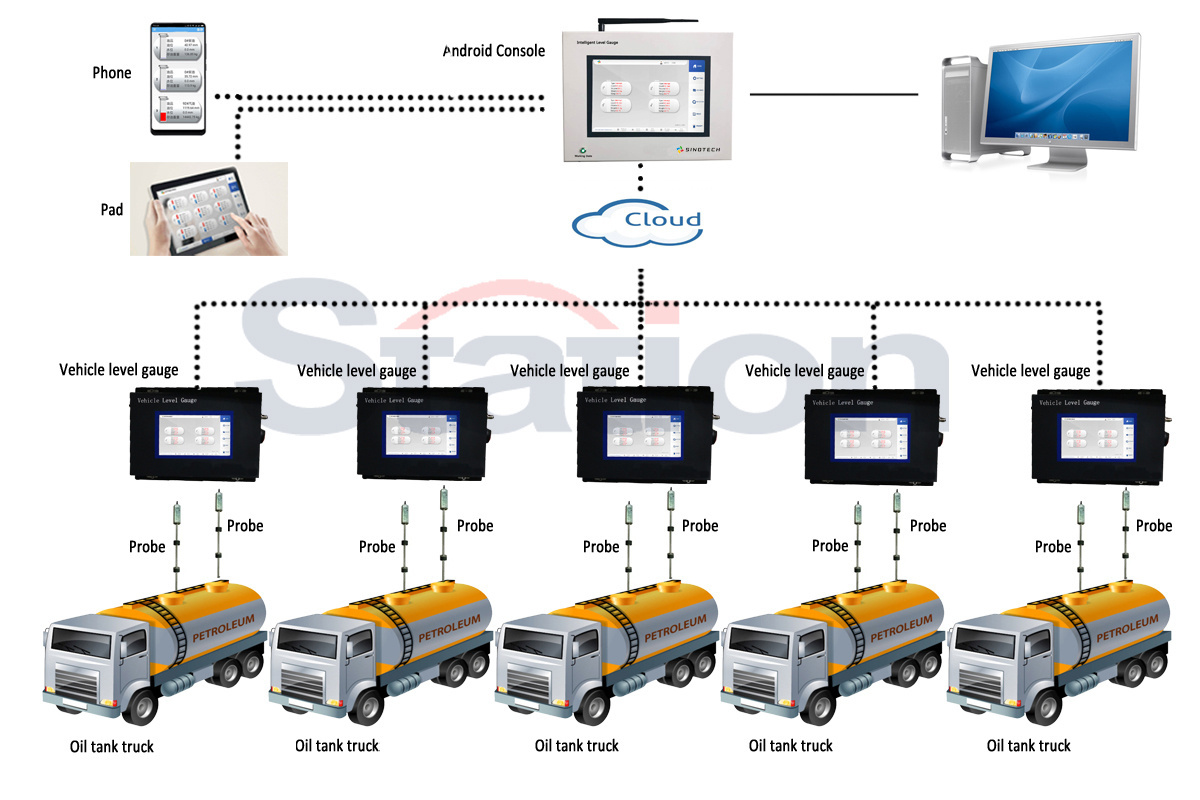

Intelligent level gauge adopts MC-Y770-101 series android screen, with 4 cores Cortex-A7 structure, the frequency of 1.2Ghz CPU, the human machine interface of 5 inch color capacitive touch screen, and the human-computer interaction is more convenient and fast; the interface adopts the industrial field bus, and it can support external sound light alarm, with optional print function, and it also can connect expansion anti-overflow valve module externally, and it can be remote controlled by mobile phone. The hardware of system adopts advanced electronic technology and good-quality electronic components, installed by lightning protection tube and TVS as well as other anti-interference equipment.

It makes the performance of the whole system more stable and the service life longer, and it has the outstanding characteristics of simple operation, convenient use and maintenance etc..

Working Principle

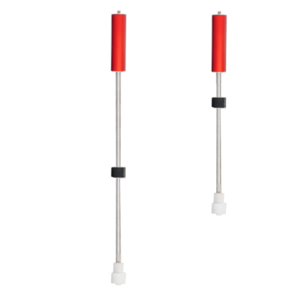

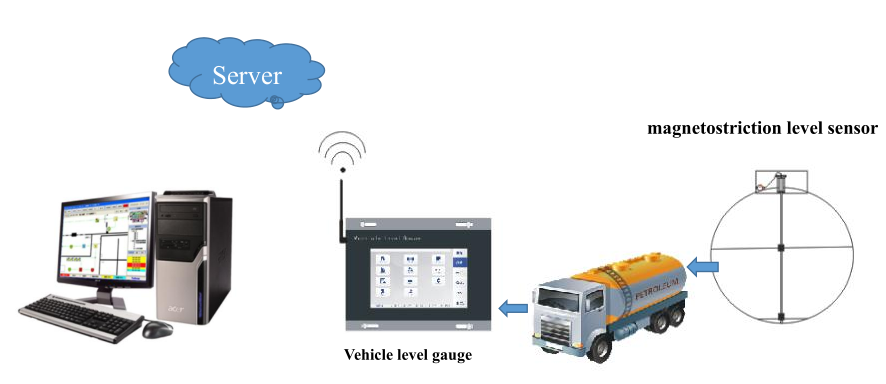

SP probes are installed in fuel tanks, the motherboard in probe head send signals to product floater and water floater in highly frequency, usually milliseconds, and floater responds and feedback to motherboard of probe.

By RWP4x0.5 shielding cable connection, SS console asks the tanks information (oil product level, water level and temperature) from SP probes in milliseconds, too. One important feature of SS console is that users can input tank volume chart into program, SS console program will automatically simulate a precisely tank module and calculate the stock volume base on measured oil height, water height and temperature value.

SS console connects to site computer by RS232, PC Remote back-office software which installed at site computer will asks tanks information from SS console in milliseconds frequency, so users can monitor tanks information from PC screen.

Base on internet connection between sites and head office, Server in head office can received the tanks information transferred from PC Remote back-office software, and store every record for inquiry in future.

More we can do for you is that when you travel or at home, it is easy to see the current conditions of each tank, just have

internet and a computer or notebook which preinstalled Inquiry software GAS-01.

(Data format IP Date Packet, Encrypted by DES)

The human machine interface adopts the 5 inch color capacitive touch screen, and Android system interface is more humanized.