- Product Details

- {{item.text}}

Quick Details

-

Nominal Force:

-

630kn

-

compression chamber:

-

1000* 600*500 mm

-

Block size:

-

(180-250) *200*200mm

-

Block density:

-

≥2000kg/m 3

-

Capacity:

-

500-1000 kg /h

-

Single cycle:

-

≤90

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

Industrial hydraulic scrap metal baling press machine

-

Power:

-

7.5kw

-

Nominal Force:

-

630kn

-

compression chamber:

-

1000* 600*500 mm

-

Block size:

-

(180-250) *200*200mm

-

Block density:

-

≥2000kg/m 3

-

Capacity:

-

500-1000 kg /h

-

Single cycle:

-

≤90

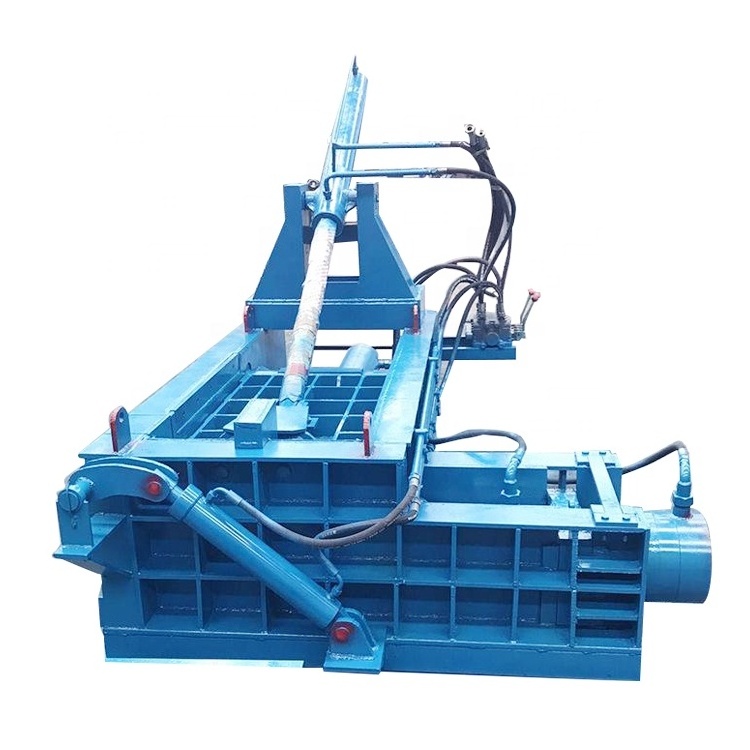

Industrial hydraulic scrap metal baling press machine

It Mainly used in recycling processing industry and metal smelting industry. Various metal scraps, steel shavings, scrap steel, scrap iron, scrap copper, aluminum scrap, aluminum shavings, dismantled car shells, waste oil drums and other metal materials can be extruded into various shapes of qualified materials such as cubes and cylinders. . Easy to store, transport and re-use.

The manure dewatering machine is used to separate slaughter dirty water, paper pump water, Chinese medicine residue, food residue, dust removal sludge, crop residue, etc.

Features of Hydraulic Waste metal block press machine :

1. All are hydraulically driven, work smoothly, safe and reliable;

2. It adopts manual or PLC automatic control;

3. The discharge form includes four types: side roll bag, side push bag, front push bag or no bag out;

4. The installation does not require a foot screw, and the diesel engine can be used in the place where there is no power supply.

5. Specification and type of Hydraulic Waste metal block press machine : Th is machine has 10 varieties and more than 20 specifications from 63 tons to 600 tons , which can meet the different needs of customers at different levels.

6. Advantages of Hydraulic Waste metal block press machine : The machine adopts hydraulic transmission, compact structure, convenient loading and loading, simple operation, easy maintenance, reliable sealing, and no foot screws for installation.

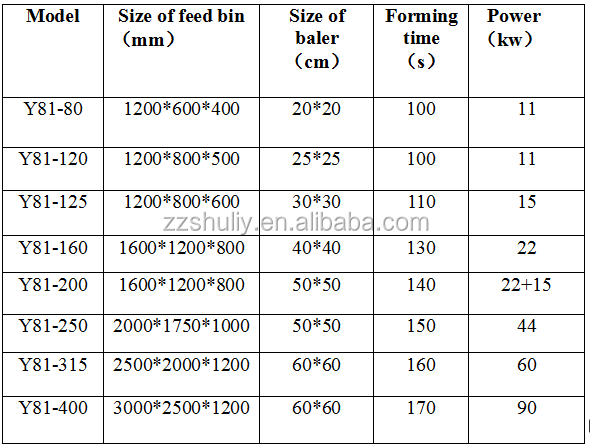

Technical parameter of metal baler

Cautions for use of hydraulic scrap iron packer:

1. Hydraulic drive is adopted in all models, manual or PLC automatic control operation is optional.

2. There are different ways of discharging material, such as turning over the package, pushing the package (side push and forward push) or manual picking up the package (packing).

3. Installation does not require sole screw, where there is no power supply, diesel engine can be used as power;

4. There are ten grades of extrusion force from 10 tons to 100 tons for users to choose.

5. Compression chamber size and package size can be customized according to customer requirements.

6. The spherical structure is used to connect the pushing cylinder and the pushing head. The reliability is good and the service life of the oil seal is long.

7. Widening and enlarging the feeding inlet, making the filling more convenient and quick.

8. Low noise hydraulic circuit design, high efficiency and low failure.

9. Horizontal structure, can be equipped with conveyor belt feeding or manual feeding. Control lever operation, PLC control, safe and reliable

Please click on our other products:

https://zzshuliy.en.alibaba.com/?spm=a2700.7756200.mamo-user-profile.4.d0d571d2op0lpE

Our services:

1.Online /sale services:

a. super and solid quality.

b.fast and punctual delivery.

c.standard export package or customized.

2.After - sale services:

a.assistance to build your project.

b.repairing and maintenance with any problems in the warranty.

c.spare parts and wearing parts for free or with big discount.

d. any feedback of the machine can be told us so that we can give you best service.

3.Other cooperation services:

a. technology knowledge share.

b.business expansion advising.

c.video technical support.