- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.03 mm

-

Number of Axes:

-

1

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

2.2kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Pratt

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

600*600

-

Power (kW):

-

2.2

-

Weight (KG):

-

600

-

Core Components:

-

spindle

-

Working area:

-

600*600mm

-

Control system:

-

NcStudio Control System

-

Spindle power:

-

2.2kw 3.0 Kw 4.5kw 6.0kw

-

Software:

-

Ucancam / ArtCam/TYPE3

-

Motor and driver:

-

Stepper Motor Leadshine Driver

-

Working table:

-

Vacuum T-slot Table

-

Guide rail:

-

Hiwin Square Linear Guide Rail

-

Driving method:

-

X,Y axis by helical gear rack, Z axis by TBI ball screw

-

Inverter:

-

Fuling Inverter

Quick Details

-

Working Table Size(mm):

-

600×600

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 2400 rpm

-

Positioning Accuracy (mm):

-

0.03 mm

-

Number of Axes:

-

1

-

Travel (X Axis)(mm):

-

600 mm

-

Travel (Y Axis)(mm):

-

600 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

2.2kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Pratt

-

Voltage:

-

220v

-

Dimension(L*W*H):

-

600*600

-

Power (kW):

-

2.2

-

Weight (KG):

-

600

-

Core Components:

-

spindle

-

Working area:

-

600*600mm

-

Control system:

-

NcStudio Control System

-

Spindle power:

-

2.2kw 3.0 Kw 4.5kw 6.0kw

-

Software:

-

Ucancam / ArtCam/TYPE3

-

Motor and driver:

-

Stepper Motor Leadshine Driver

-

Working table:

-

Vacuum T-slot Table

-

Guide rail:

-

Hiwin Square Linear Guide Rail

-

Driving method:

-

X,Y axis by helical gear rack, Z axis by TBI ball screw

-

Inverter:

-

Fuling Inverter

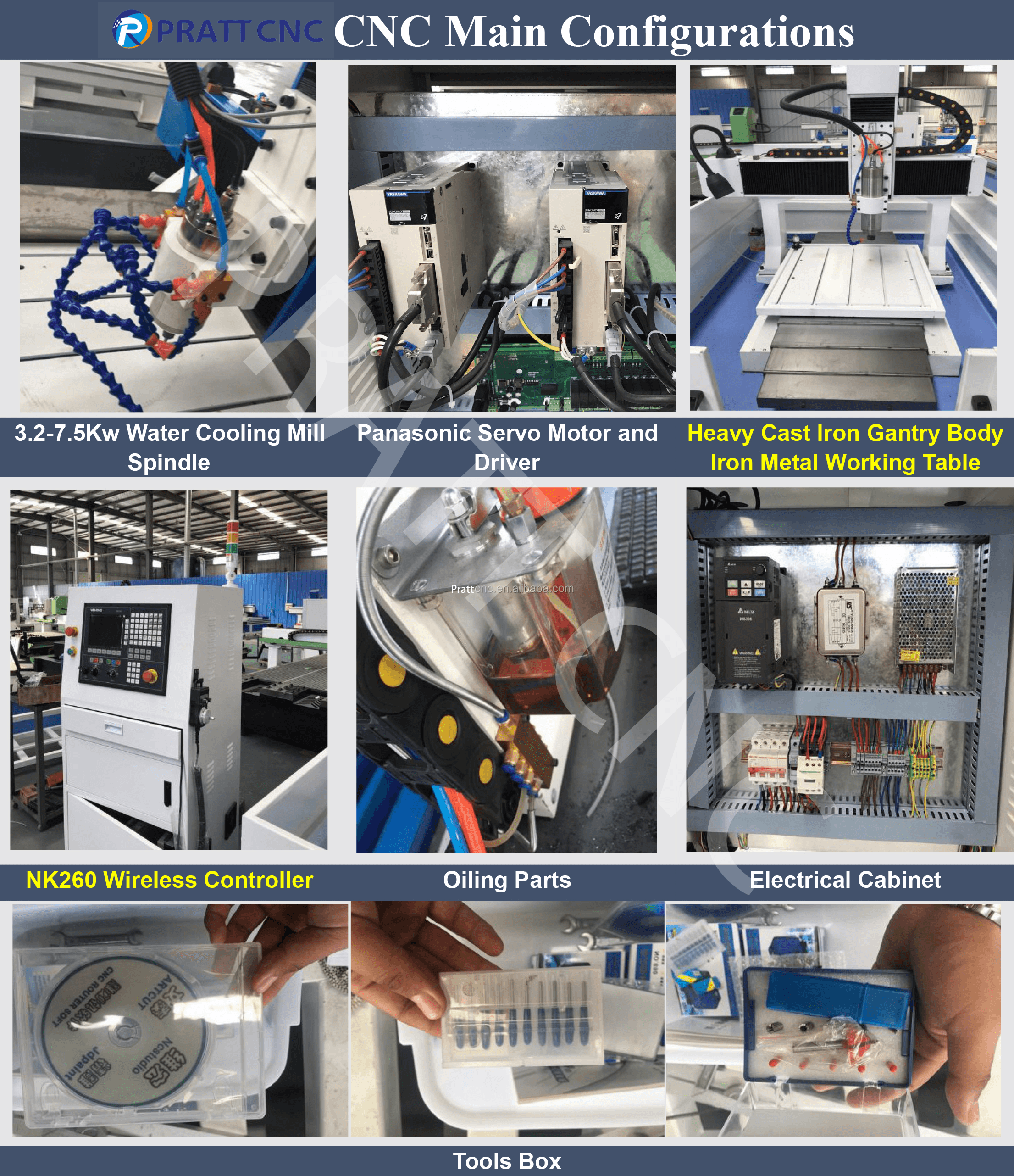

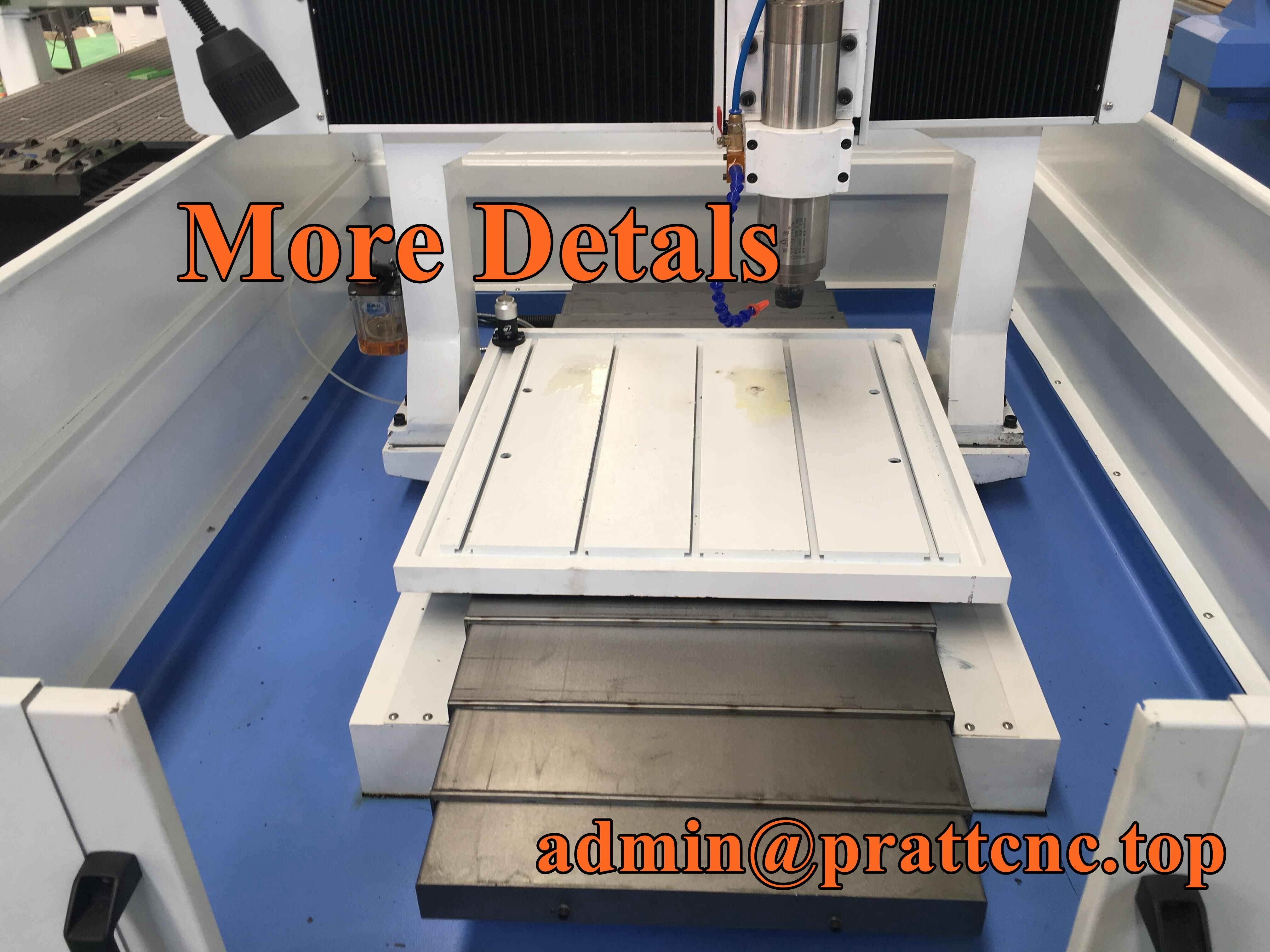

3D CNC ROUTER METAL Milling Machine 600*600mm

Applicable Industries:

Good at in processing all kinds of small workpiece ,widely used in advertising signs, badges, logo, mould construction equipment, mould products, industrial mold, etc.

Applicable Materials:

Suitable for all kinds of metal, such as copper, aluminum, iron, stell, stainless steel, alloy, also the acrylic, wood, MDF, double color board, stone, jade, ect.

Brief introduction of metal CNC engraving machine CNC 6060:

1. The cast iron frame is subjected to vibration aging treatment to ensure that the machine is not easily deformed.

2. The imported ball screw drive is X Y Z axis, with good stability, high precision and long service life.

3. Linear circular guide, optional: Taiwan HIWIN linear square guide, diameter 20mm, longer life and more durable

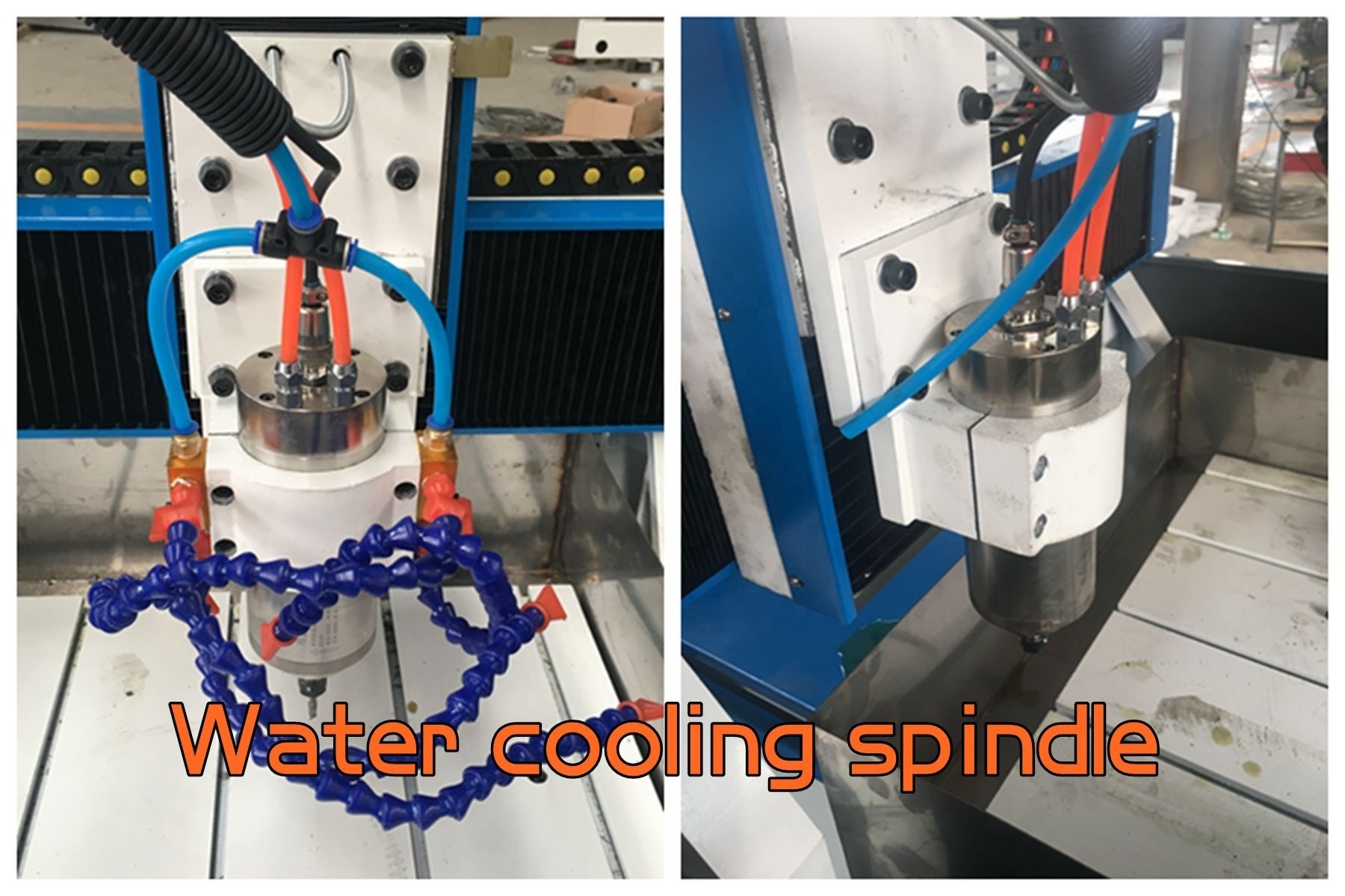

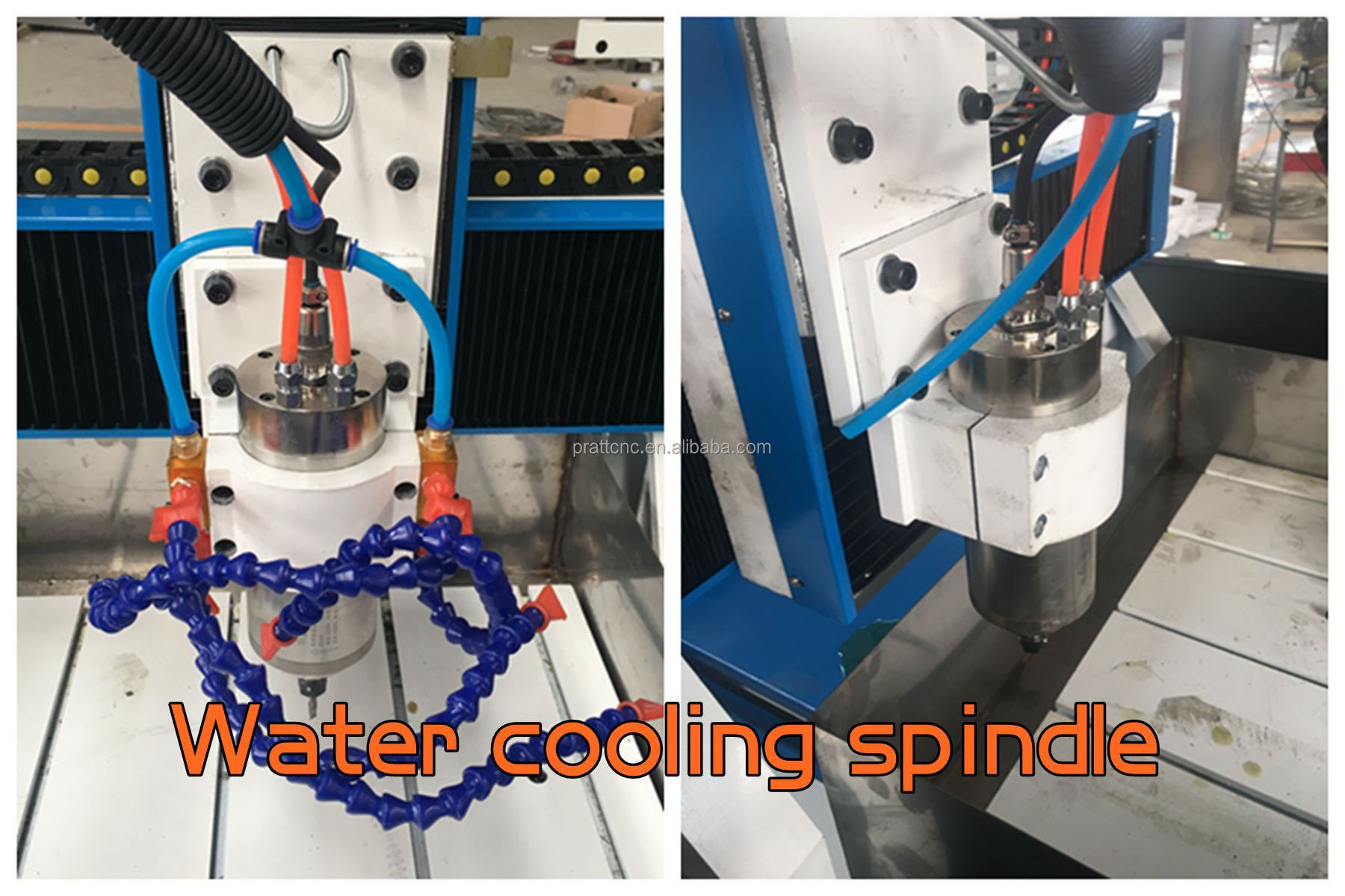

4. Stainless steel sink cooling system for cooling tools and materials required for metal and stone/glass processing.

5.DSP NK105 Control system

6. W ater cooling spindle

7. Can realize multi-layer 3D processing, fast speed, smooth three-dimensional processing, engraving and cutting.

8. Emergency stop button to ensure safe operation.

9. Good software compatibility, suitable for CAD/CAM design software such as Type3, Artcam, Castmate, Ucanam, et

Certificate and factory

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.