- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Wensui

-

Voltage:

-

380VAC 3 phase 50Hz

-

Dimension(L*W*H):

-

3710*2880*2530mm

-

Power (kW):

-

90

-

Weight (T):

-

11

-

Item/Model:

-

DS260

-

Crushing chamber(mm):

-

600*460

-

Rotor diameter(mm):

-

300

-

Rotor speed(RPM):

-

85

-

Pusher stroke(mm):

-

300

-

Rotor knife qty(pcs):

-

30

-

Screen opening(mm):

-

Dia. 40

-

Motor power(kw):

-

11

Quick Details

-

Max.Production Capacity (kg/h):

-

200000

-

Place of Origin:

-

Guangdong, China

-

Production Capacity (kg/h):

-

1000 - 2000 kg/h

-

Brand Name:

-

Wensui

-

Voltage:

-

380VAC 3 phase 50Hz

-

Dimension(L*W*H):

-

3710*2880*2530mm

-

Power (kW):

-

90

-

Weight (T):

-

11

-

Item/Model:

-

DS260

-

Crushing chamber(mm):

-

600*460

-

Rotor diameter(mm):

-

300

-

Rotor speed(RPM):

-

85

-

Pusher stroke(mm):

-

300

-

Rotor knife qty(pcs):

-

30

-

Screen opening(mm):

-

Dia. 40

-

Motor power(kw):

-

11

Product Images

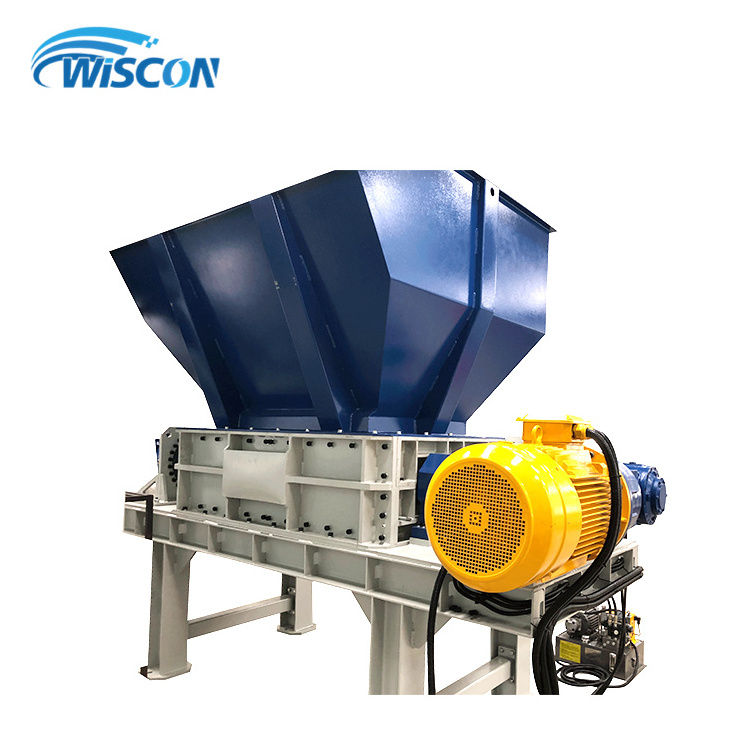

Exceptionally High torque to Smash It All

The DS series of the double shaft shredder can handle a wide range of solid wastes. Compared to single shaft shredder, this series has a lower speed, higher torque, and higher efficiency. Its structure is relatively compact and maintenance-friendly with maintenance door that provides full access to crushing chamber and bearing houring.

Because the shredder is screenless, it is often used as primary shredding, and its shredded particle size depends on the blade thickness.

Applications

RDF(Refuse Derived Fuel): MSW, industry waste, wood, paper, tires, plastics, etc.

Metal materials: Aluminum, ferrous, non-ferrous, steel drum, waste automative, etc.

Electronics: WEEE, aluminum product, building material, sheet, etc.

Plastic: Plastic drum, plastic lump, films, etc.

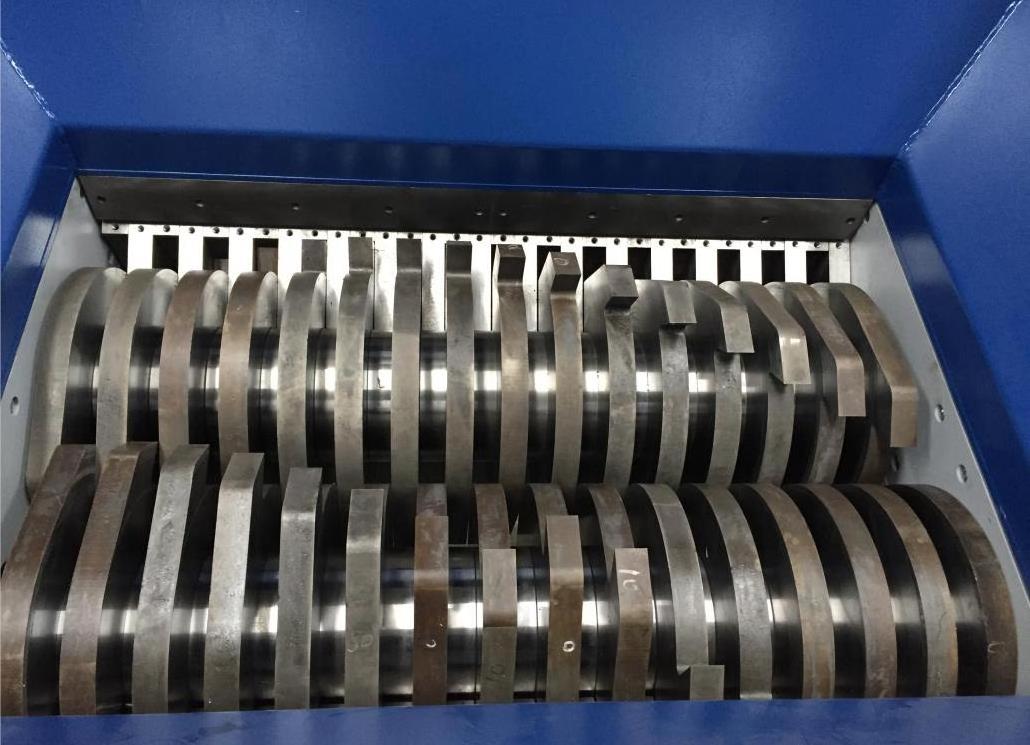

Features

> Rotor knife adopts DC53 steel and counter knife adopts D2 steel.

> Main electrical components are trusted brands such as Siemens and Schneider.

> Automatic-reverse system re-orients rotor direction in case of motor overload and material jam.

> Easy access to rotor and screen, and quick to change them.

> Rotor knives can be used 2 times before replaced, reducing operating cost.

> The gap between counter knives and rotor is adjustable.

> Several models of screen are available and easily interchangeable.

> Guide rail and pusher can be replaced and are adjustable to maintain a smooth push and retract as well as to keep crushing chamber fully closed.

> Rotor knife adopts DC53 steel and counter knife adopts D2 steel.

> Main electrical components are trusted brands such as Siemens and Schneider.

> Automatic-reverse system re-orients rotor direction in case of motor overload and material jam.

> Easy access to rotor and screen, and quick to change them.

> Rotor knives can be used 2 times before replaced, reducing operating cost.

> The gap between counter knives and rotor is adjustable.

> Several models of screen are available and easily interchangeable.

> Guide rail and pusher can be replaced and are adjustable to maintain a smooth push and retract as well as to keep crushing chamber fully closed.

Product Parameters

|

Item/Model

|

DS260

|

DS280

|

DS380

|

DS3120

|

|

Crushing chamber(mm)

|

600*460

|

800*460

|

800*720

|

1200*720

|

|

Rotor diameter(mm)

|

300

|

300

|

450

|

450

|

|

Rotor speed(RPM)

|

85

|

85

|

85

|

85

|

|

Blade thickness(mm)

|

20

|

20

|

20/40

|

20/40

|

|

Rotor knife qty(pcs)

|

30

|

40

|

40/20

|

60/30

|

|

Screen opening(mm)

|

Φ40

|

Φ40

|

Φ40

|

Φ40

|

|

Motor power(kw)

|

5.5+5.5

|

7.5+7.5

|

15+15

|

22+22

|

|

Dimension(mm)

|

2500*1180*1830

|

2740*1180*1830

|

3060*1850*2230

|

3580*1970*2230

|

|

Weight(kg)

|

2000

|

2250

|

4300

|

5800

|

Hot Searches