Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

oil seal

-

Material:

-

Custom Compound

-

Service:

-

Customize Special Sizes

-

Feature:

-

Oil Resistance

Quick Details

-

Size:

-

37*66*9.5/12

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DINGTONG, DINGTONG

-

Model Number:

-

oil seal

-

Material:

-

Custom Compound

-

Service:

-

Customize Special Sizes

-

Feature:

-

Oil Resistance

Product Paramenters

|

Name

|

TC OIL SEAL/TG OIL SAEL/OEM OIL SEAL

|

|

|

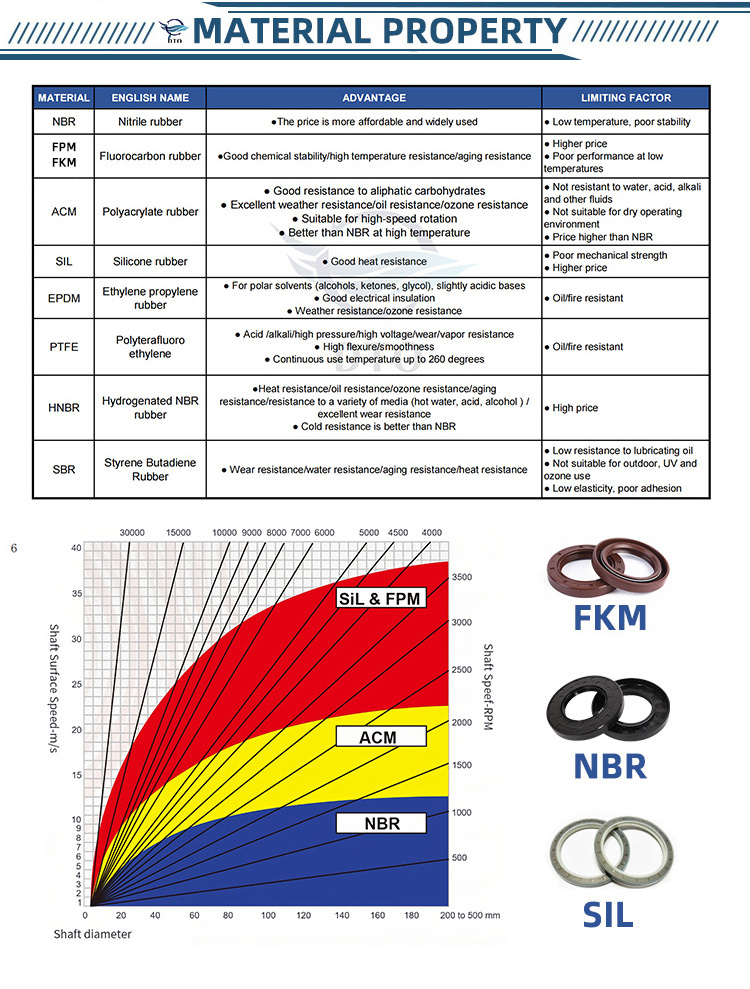

Material Type

|

NBR/FKM

|

|

|

Hardness Range

|

20-90 Shore A

|

|

|

Color

|

Any color is OK

|

|

|

Size

|

As per drawing dimensions

|

|

|

Tolerance Standard

|

ISO2768-M or ISO3302-1:2014 CLASS M2

|

|

|

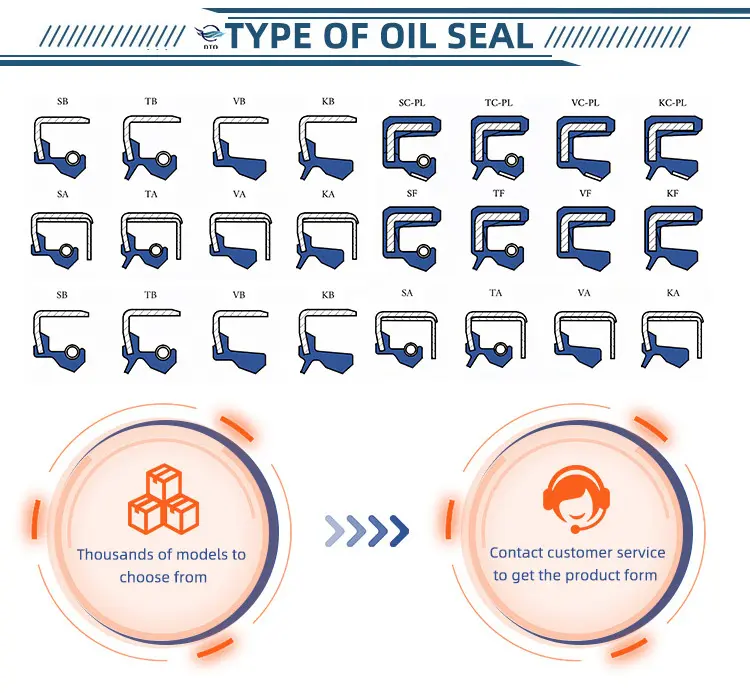

Material Characteristic

|

See below rubber materials properties

|

|

|

Application

|

For all industries

|

|

|

Certificates

|

U L, NSF61, KTW, W270, ACS, AS4020, WRAS, EN681, EN549, ROHS, REACH, USP CLASS VI

|

|

|

OEM / ODM

|

Available

|

|

|

Packing Details

|

Paper bags, plastic bags, cartons, can be customized

|

|

|

Production Capacity & Lead Time

|

|

|

|

Production Capacity

|

3000 tons per month

|

|

|

Lead Time

|

7 days for prototype tooling & samples, 14 days for production mold, 14-28 days for MOQ

|

|

|

Shipping & Payment Terms

|

|

|

|

Port of Loading

|

XiaMen/other port as you want

|

|

|

Shipping Method

|

SEA,AIR,DHL,UPS,FEDEX,TNT, etc.

|

|

|

Payment Terms

|

T/T, L/C, Paypal, Western Union

|

|

|

Rubber Specification & Inspection Standard

|

|

|

|

Rubber Specification

|

ASTM D2000, SAE J200

|

|

|

Quality Acceptance Criteria

|

According to customer's requirements

|

|

manufacturer

Xingtai Dingtong Rubber is a professional products co., Ltd. production and sales of seals enterprises. Founded in 1996, it covers an area of 23,300 squaremeters, 26 machines, and 3200 kinds of molds. Our products are often exported to North America, Asia, Europe, Northern Europe, Southeast Asia, South Asia, Asia, South America, Africa.

FACTORY INTRODUCTION

Xingtai Dingtong Rubber & Plastic Products Co., Ltd. has been committed to the rubber sealing industry.We have more than 20 years of experience in the production of rubber seals.The main products are oil seal, O-ring, hydraulic seal, gasket, floating seal and OEM rubber parts. The company is located in Nanzhouzhang Industrial Zone, Pingxiang County, Xingtai City, Hebei Province, covering anarea of more than 20,000 square meters At present, there are more than 15,000 kinds of products, selling in China,Southeast Asia, Europe and the United States and other

regions, and can come to sample and map processing. Excellent quality, on-time delivery, reasonable price, thoughtful pre-sales and after-sales service, has been praised by our customers. Welcome friends from all walks of life to visit, guidance and business negotiations.

regions, and can come to sample and map processing. Excellent quality, on-time delivery, reasonable price, thoughtful pre-sales and after-sales service, has been praised by our customers. Welcome friends from all walks of life to visit, guidance and business negotiations.

FAQ

Q 1. What's the payment term?

A: We accept T/T 30% deposit and 70% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Generally it is 1-2 days if the goods are in stock. or it is 5-10 days if the goods are not in stock, it is according to quantity.

Q 3. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q 4. Could you please tell us the month capacity of your products ?

A: It depends on which model, we produce more than 2500 tons rubber materials per month.

Q 5. what kind of certificates you have ?

A1: We have been ISO9001:2008 and ISO14001:2004 certified by S G S since 2005.

A2: We have various rubber compounds approved by UL, F DA, NSF, KTW, W270, WRAS, ACS,AS4020, EN681,

EN549, ROHS and REACH.

Q6: How to check the quality of the bulk order?

A1: We provide preproduction samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet, Coo, CoA, etc. to all customers before delivery.

A3: We accept third party inspection such as S GS, TUV, INTERTEK, BV, etc.

Q7: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Q 8: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.

Q9:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.

Q10: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM(FKM), NEOPRENE(CR), NR, IIR, SBR, ACM, AEM,Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q 11: What other services does Maihua Rubber offer?

A: Maihua Rubber has in-house tooling capabilities for molds; we have our own lab for material testing; we have a Cold Room used for elastomer storage to prolong product life.

Q 12: What is the life expectancy of the rubber seal?

A: Product life is contingent upon many factors, including environment, cycles, pressure, etc. Maihua Rubber cannot predict seal life under all the varying conditions of operation. Accellerated life testing may be performed by customer to determine expected life, but must be conducted in dynamic application.

Q13:

Does DTO provide tool maintenance?

DTO Rubber maintains all tools and replaces them as needed.

Q14: How many empolyees you have?

A:We have 50 empolyees at time of December 2023

.

Q15: How many shifts per day in the factory?

A: Two shifts per day, 8 hours per shift.

Hot Searches