- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Elastomer

-

Rated Voltage:

-

600V

-

Tensile Strength:

-

14 MPa Min.

-

shrink ratio:

-

2:1

-

Operating temperature:

-

-75 to 150℃

-

Standard:

-

AMS-DTL-23053/16

-

Standard color:

-

black

-

Feature:

-

oil resistant

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KEHONG

-

Model Number:

-

DR-150

-

Material:

-

Elastomer

-

Rated Voltage:

-

600V

-

Tensile Strength:

-

14 MPa Min.

-

shrink ratio:

-

2:1

-

Operating temperature:

-

-75 to 150℃

-

Standard:

-

AMS-DTL-23053/16

-

Standard color:

-

black

-

Feature:

-

oil resistant

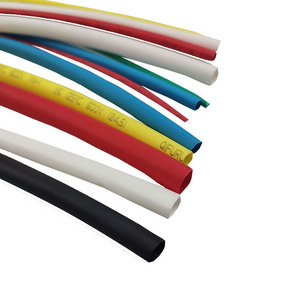

DR-25-TW/DERAY V25 TW equivalent Oil proof heat shrink tubing

DR-150

Diesel-resistant, flexible, flame-retardant elastomer tubing

1) Application

With resistance to aviation and diesel fuels, hydraulic fluids, and lubricating oils, DR is ideal for applications require resistance to fuels, fluids and solvents. It is particularly suitable for protecting and bundling of high-performance cables and wiring harnesses.

2) Features/Benefits

Shrink ratio: 2:1

Outstanding fluid and heat resistance.

Abrasion resistance and excellent mechanical properties.

Flexible, flame-retardant.

Conform to European RoHS environmental directive.

3) Operating Temperature Range

Operating temperature range: -75 ℃ ~150 ℃

Minimum full recovery temperature: 175 ℃

4) Specifications/Standards

AMS-DTL-23053/16

5) Specification values

|

|

Property |

Requirement |

Test method |

Typical value |

|

Physical : |

Tensile strength |

11.7MPa min. |

ASTM D 638 |

≥14MPa |

|

Elongation |

250% min. |

ASTM D 638 |

≥350% |

|

|

Heat shock 250 ℃ , 4hrs |

No cracking, dripping or flowing |

ASTM D 2671 |

Pass |

|

|

Low temperature flexibility -75 ℃ , 4hrs |

No cracking |

ASTM D 2671 |

Pass |

|

|

Aging 150 ℃ , 168hrs |

||||

|

Tensile strength after aging |

10.3MPa min. |

ASTM D 638 |

≥12MPa |

|

|

Elongation after aging |

200% min. |

ASTM D 638 |

≥300% |

|

|

Electrical : |

Dielectric voltage withstand |

2500V,60sec,no breakdown |

ASTM D 2671 |

Pass |

|

Dielectric strength |

11.9KV/mm min. |

ASTM D 2671 |

≥11.9KV/mm |

|

|

Volume resistivity |

10 9 Ω·cm min. |

ASTM D 876 |

≥10 9 Ω·.cm |

|

|

Chemical : |

Corrosion |

No corrosion |

ASTM D 2671 |

Pass |

|

|

Flammability |

Self extinguishing within 1 minute |

ASTM D 2671 |

Pass |

|

Fluid resistance : |

23 ℃ , 24hrs (aviation and diesel fuels, hydraulic fluids, lubricating oils, etc.) |

|||

|

|

Tensile strength |

10.4MPa min. |

ASTM D 2671 |

≥12MPa |

|

|

Elongation |

200% min. |

ASTM D 2671 |

≥300% |

|

|

Dielectric strength |

7.9KV/mm min. |

ASTM D 2671 |

≥9.0KV/mm |

6) Product sizes mm/inch

|

Size |

Inside diameter |

Wall thickness |

Standard length (m/spool) |

|

|

As supplied ( min. ) |

After recovery ( max. ) |

After recovery |

||

|

1/8 |

3.2 ( 0.125 ) |

1.6 ( 0.062 ) |

0.76±0.15 ( 0.030±0.006 ) |

100 |

|

3/16 |

4.8 ( 0.187 ) |

2.4 ( 0.093 ) |

0.84±0.15 ( 0.033±0.006 ) |

100 |

|

1/4 |

6.4 ( 0.250 ) |

3.2 ( 0.125 ) |

0.89±0.15 ( 0.035±0.006 ) |

100 |

|

3/8 |

9.5 ( 0.375 ) |

4.8 ( 0.187 ) |

1.02±0.20 ( 0.040±0.008 ) |

50 |

|

1/2 |

12.7 ( 0.500 ) |

6.4 ( 0.250 ) |

1.22±0.20 ( 0.048±0.008 ) |

30 |

|

3/4 |

19.1 ( 0.750 ) |

9.5 ( 0.375 ) |

1.45±0.28 ( 0.057±0.011 ) |

30 |

|

1 |

25.4 ( 1.000 ) |

12.7 ( 0.500 ) |

1.78±0.28 ( 0.070±0.011 ) |

30 |

|

1 1/2 |

38.1 ( 1.500 ) |

19.0 ( 0.750 ) |

2.41±0.41 ( 0.095±0.016 ) |

15 |

|

2 |

50.8 ( 2.000 ) |

25.4 ( 1.000 ) |

2.79±0.41 ( 0.110±0.016 ) |

22 |

7) Ordering Information

Color

Standard: Black (-BK)

Nonstandard colors can be available upon request.

Nonstandard size

Nonstandard sizes are available upon request.

Standard packaging

On spools.

Why is Polyolefin Tubing a good heat shrinkable tubing choice?

Polyolefin Shrink Tubing is a popular selection among the heat shrink tubing family because Polyolefin is flame-retardant and possesses good chemical, electrical and physical properties. In general, Polyolefin Tubing is a reliable all purpose heat shrink product and is UL recognized. The heat shrinkable tubing is also available in many different styles for various uses. Sometimes Polyolefin heat shrink tubing is also referred to as Automotive Heat Shrink Tubing, so it may be a good choice for automotive applications.

Is installation of the heat shrinkable tubing difficult?

No, in most instances, heat shrink tubing is very easy to work with and simple to install.Heat shrink tubing is available in an array of sizes and colors, step1 find the correct size of tube to the wire, heat the tube with hot gun, then the tube will shrink on to the wire.

KeHong Enterprises Co.,Ltd.

No,7118,Floor 7, Sha Feng Business Building,

Jin sha zhou, Baiyun District,Guangzhou,China.

www.heatshrinkstar.com

www.khenterprise.en.alibaba.com

Tel:+86-20-82586869, Mobile: +8615918777767

Wechat:008615918777767

Skype:gonggulily