- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

customizable

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

nano ceramic wear-resistant coating

-

Brand Name:

-

Rongsheng

-

Product name:

-

refractory coating

-

Al2O3+SiC+ZrO2%:

-

≥85%

-

Sample:

-

Sample Provided

-

Type:

-

refractory material for coreless induction furnace

-

Usage:

-

Furnace Liner

-

Feature:

-

Thermal Shock Resistance

-

Application:

-

CFB boiler lining

-

Max. working temperature ℃:

-

1700

-

Package:

-

Wooden Pallet

-

Certificate:

-

CE ISO

Quick Details

-

SiO2 Content (%):

-

customizable

-

Al2O3 Content (%):

-

≥70%

-

MgO Content (%):

-

customizable

-

CaO Content (%):

-

customizable

-

CrO Content (%):

-

0.1~0.3%

-

SiC Content (%):

-

customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

nano ceramic wear-resistant coating

-

Brand Name:

-

Rongsheng

-

Product name:

-

refractory coating

-

Al2O3+SiC+ZrO2%:

-

≥85%

-

Sample:

-

Sample Provided

-

Type:

-

refractory material for coreless induction furnace

-

Usage:

-

Furnace Liner

-

Feature:

-

Thermal Shock Resistance

-

Application:

-

CFB boiler lining

-

Max. working temperature ℃:

-

1700

-

Package:

-

Wooden Pallet

-

Certificate:

-

CE ISO

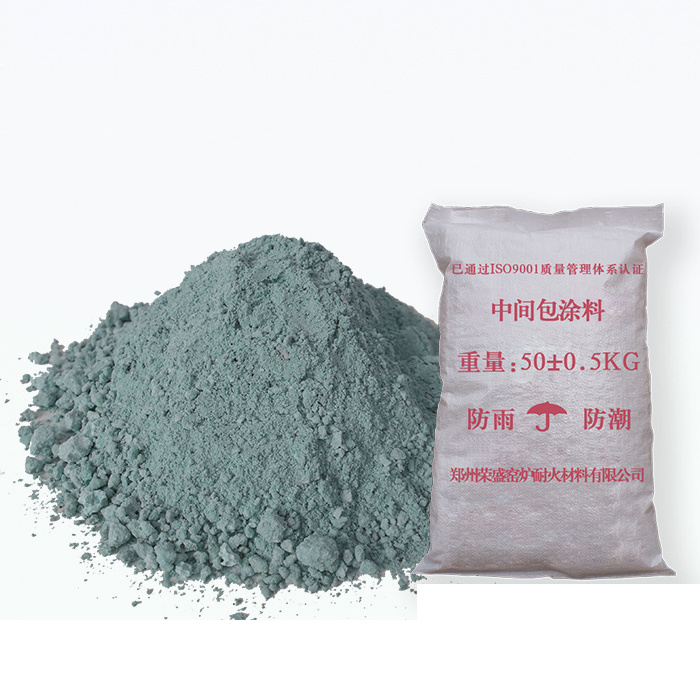

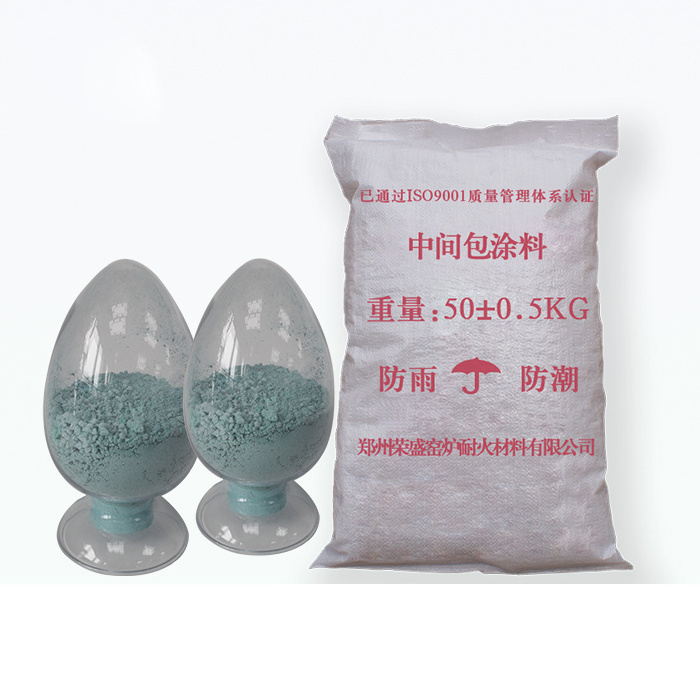

High temperature unshaped refractory material alumina refractory coating for aluminum zinc melting coreless induction furnace

Because of its excellent characteristics such as high strength, excellent wear resistance, and close bonding with the substrate, refractory coatings are suitable for areas below 1300 degrees, high wind speeds, severe wear, and other areas with high wear resistance requirements. Refractory coatings are widely used in the severely worn areas of large CFB boilers, which can save time for furnace dismantling and maintenance and prolong the service life of masonry by quickly constructing on the surface.

Semi-light weight and light weight refractory coating can be used as a thermal insulation lining, but also as a working lining for heat preservation and heat insulation at low and medium temperature. It has the characteristics of convenient construction, high adhesion, low rebound rate, and low working strength.

[Advantage] The hot ceramic wear-resistant and fire-resistant coating developed by Rongsheng has successfully solved the problems of CFB boiler, vaporization furnace, fluidized bed furnace and gas cooled separator that require a lot of manpower, material resources, financial resources, time, damage and heating surface in the process of removal and maintenance.

[Rapid repair of the furnace] With this product, it is unnecessary to remove the original foundation, but only need to apply a layer of paint on the surface of the raw material foundation to ensure the safe use of the heating surface. Short maintenance time, low cost, convenient and quick, without baking, it is the ideal fast repair product at present.

[Features] It has strong cohesive force, no sedimentation, no flowing, good workability and usability, and full masonry joints.

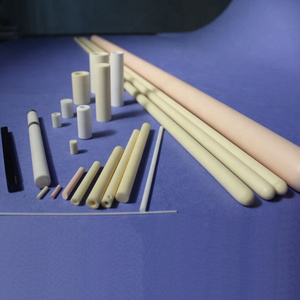

Application of Refractory Coating

Refractory Coating Applicable to CFB boiler lining matching with corresponding refractory bricks (not applicable to other kilns that react with P205). Especially, it is applicable to the construction of separator target area, circulating fluidized bed vaporizer outlet, separator and other parts.

Refractory Coating Technique Data

| Item | Nano Ceramic Wear-resistant Coating Specification |

| Al2O3+SiC+ZrO2% | ≥85 |

| Wear Loss , cm3 | ≤4 |

| Item | Specification | |||

| LGP0.8 | LGP1.0 | LGP1.3 | ||

| Al2O3 % | ≥30 | ≥35 | ≥40 | |

| Bulk Density,g/cm3 110℃×24h | ≤0.8 | ≤1.0 | ≤1.3 | |

| CCS, MPa | 110℃×24h | ≥4 | ≥5 | ≥7 |

| Test Temperature, ×3h | ≥3 800℃ | ≥4 1000℃ | ≥5 1200℃ | |

|

PLC, %

Test Temperature, ×3h |

±0.8

800℃ |

±0.8

1000℃ |

±0.8

1200℃ |

|

| Thermal Conductivity, W/(m·K) 350℃±25℃ | ≤0.21 | ≤0.25 | ≤0.35 | |

| Test Temperature, ℃ | 800 | 1000 | 1200 | |

| Item | Specification | |||

| LGP1.5 | LGP1.8 | LGP1.8T | ||

| Al2O3 % | ≥42 | ≥45 | ≥55 | |

| Bulk Density,g/cm3 110℃×24h | ≤1.5 | ≤1.8 | ≤1.8 | |

| CCS, MPa | 100℃×24h | ≥12 | ≥15 | ≥12 |

| Test Temperature, ×3h | ≥10 1300℃ | ≥13 1300℃ | ≥10 1400℃ | |

|

PLC, %

Test Temperature×3h |

±0.8

1300℃ |

±0.8

1300℃ |

±1.0

1400℃ |

|

| Thermal Conductivity, W/(m·K) 350℃±25℃ | ≤0.4 | ≤0.7 | ≤0.75 | |

| Max Working Temperature, ℃ | 1300 | 1300 | 1500 | |

Unshaped Refractory Materials

Note: General cargo is bulk mixture, all products must do waterproof measures during the transportation and storage, it is prohibited to use if the goods appear agglomeration.