- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

igoldencnc

-

Year:

-

2020

-

Voltage:

-

AC220V / 20HZ

-

Dimension(L*W*H):

-

1300mm X 1300mm X 3000mm

-

Weight (KG):

-

12100 KG

-

Working table effective cutting size:

-

1300mm X 1300mm X 3000mm

-

System resolution:

-

± 0.04

-

File format:

-

G code

-

Worktable structure:

-

Thickened square tube welding

-

Working voltage:

-

AC220V / 20HZ

-

Transmission mode:

-

rack drive

Quick Details

-

Max.Product Size(L)(mm):

-

1300 mm

-

Max.Product Size(W)(mm):

-

1300 mm

-

Max.Product Size(H)(mm):

-

3000 mm

-

Place of Origin:

-

China

-

Brand Name:

-

igoldencnc

-

Year:

-

2020

-

Voltage:

-

AC220V / 20HZ

-

Dimension(L*W*H):

-

1300mm X 1300mm X 3000mm

-

Weight (KG):

-

12100 KG

-

Working table effective cutting size:

-

1300mm X 1300mm X 3000mm

-

System resolution:

-

± 0.04

-

File format:

-

G code

-

Worktable structure:

-

Thickened square tube welding

-

Working voltage:

-

AC220V / 20HZ

-

Transmission mode:

-

rack drive

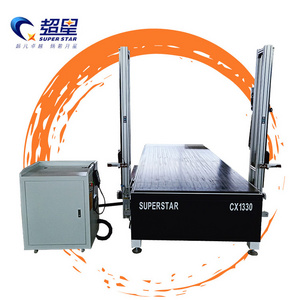

igoldencnc cnc wire polyurethane laser foam cutting machine price

Performance characteristics:

-

The CNC machining machine adopts independent gantry design, gantry can cut benzene board materials in batches.

Processing accuracy industry first! All mounting surfaces are machined precisely to ensure accurate operation. -

Cutting software CAXA and AUTOCAD drawings with full Chinese operation can be cut without scanning,coding and programming. It also has on-line simulation function. It is very convenient to use and easy to leam.

-

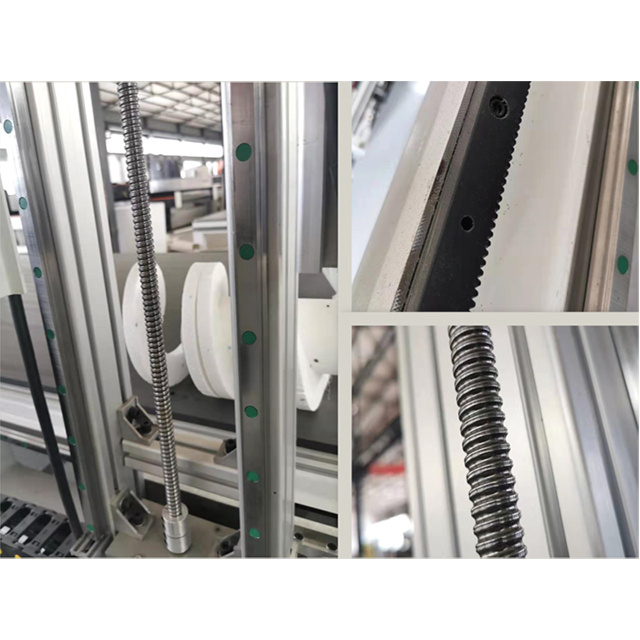

The transmission system adopts Taiwan-made ball screw and straight-line square rail, with precise transmission without clearance and low noise. It differs from other companies that generally use chains, belts or ordinary fine threaded screw rods. Its service life and precision are vastly different.

-

The overall design adopts the structure of large-scale NC machine tools, and the whole bed adopts the finishing milling of large-scale five-sided milling processing center to maximize the verticality and horizontality of the equipment.

-

All the tables are made of 20m thick high density polyester board, which is milled by the processing center again to ensure the maximum level of the tables, and marked with positioning line and center line, with minimal details.

-

All the control lines adopt flexible shielded cables, high wear resistance, flame retardant, super flexible and bending resistance.

-

The control host adopts a brand-new professional industrial computer or DSP handle.

Foam cutting machine parameters:

| Working table effective cutting size | 1300mm X 1300mm X 3000mm |

| X-axis cutting stroke | 3000mm |

| Y axis travel | 1300mm |

| System resolution | ± 0.04 |

| Cutting accuracy | ± 1mm (electric heating wire material, environment, dry humidity of foam, etc.) |

| File format | G code |

| Worktable structure | Thickened square tube welding |

| Working voltage | AC220V / 20HZ |

| Transmission mode | rack drive |

|

Note: The X and Y axis strokes are different depending on the model of the machine. (Table size can be customized)

|

|

| Drawing software | AotoCAD |

| Drive system | Mach3 |

| Support rail | Taiwan linear square rail |

| Transmission screw | Taiwan ball screw |

| Transmission rack | domestic high-precision rack |

| Driver | Lei Sai 860 driver |

| Drive motor | high-speed stepper motor |

| Control cabinet | export cabinet |

| Worktop | high-density polyester board |

| Control computer | professional solid-state hard disk industrial control computer |

| Voltage regulator power | 1KVA |

Bed frame

IGOLDENCNC foam cutting machine body is welded with thickened square tube (70 * 140/100 * 200). After five-sided milling, the flattened rail rack surface is milled to ensure the accuracy of equipment operation. It is different from small manufacturers adopting on-site welding and assembly of thin square tubes to ensure the stability of equipment operation and the durability of equipment.

Jiabang foam cutting machine weighs about 800 kilograms, and its operation is more stable. Most of the common beds in the market use 30 * 60 square tubes, and the weight of the whole machine is less than 200 kg. The operation is trembling and the cutting error is large.

Dragon Gate

IGOLDENCNC foam cutting machine is the first gantry in the industry to use aluminum profile material, which is light in weight and not easy to deform. It is different from the common equipment on the market that uses square tube welding: it is top-heavy and it shakes during operation, which affects the processing accuracy.

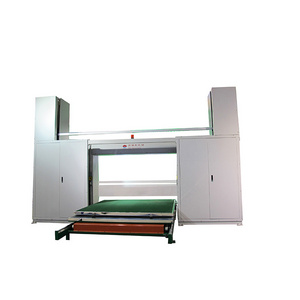

Table

IGOLDENCNC foam cutting machine table adopts 20mm thick high-density polyester board, which is not deformed and resistant to high temperature. And the use of machining center precision milling to ensure the flatness of the table. The table is equipped with positioning lines to facilitate the alignment of the feeding. Most of the manufacturers in the market use wooden board, glass, thin aluminum sheet or even no table. It cannot be avoided that the cutting error caused by the deformation of the table top is large. Affect the use effect

Transmission

IGOLDENCNC equipment adopts high-precision square linear guide, with high-precision helical rack, high-precision ball screw. Adopt double guide rails plus one screw transmission mode, high precision, long service life, large contact surface, strong load carrying capacity, the use of vertical rail technology can better ensure the stability of operation.

Most of the common equipment in the market use round rails or square rails of ordinary small brands, and the contact area is small. The device is not running smoothly.

Beam fixing method

The beam of IGOLDENCNC foam cutting machine adopts hanging plate fixing method, which makes the equipment run more stable and have higher precision.

It is different from the common equipment beams on the market that squat directly on the bed, and it takes a long time to shake due to the heavy gantry welded by the square tube. Affect the processing accuracy.

Drag chain

IGOLDENCNC numerical control cable national standard grade flexible cable, high quality and long service life. And fixed by towline, anti-interference, anti-winding.

Different from the inferior towline of common foam cutting machine on the market, the durability is higher.

Jinan iGolden CNC Equipment Co.,Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc.

And welcome to visit https://igoldencncrouter.en.alibaba.com/ for more choices and info.