- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

91 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After sale service:

-

Spare parts supply

-

Product Name:

-

Continuous Cement Ball Mill

-

Application:

-

Granite, Basalt, Quartz, Fldspar etc.

-

Warranty period:

-

More than 12 months

-

Feeding size:

-

≤25mm

Quick Details

-

Capacity(t/h):

-

15-160

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

UNIQUE

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

91 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

After sale service:

-

Spare parts supply

-

Product Name:

-

Continuous Cement Ball Mill

-

Application:

-

Granite, Basalt, Quartz, Fldspar etc.

-

Warranty period:

-

More than 12 months

-

Feeding size:

-

≤25mm

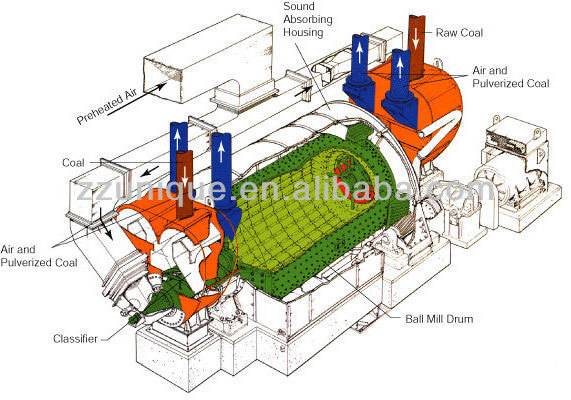

Introduction of Energy-saving grid Ball Mill

Energy-saving grid (overflow) ball mill is the key equipment after the material is broken and crushed.They are used for dry or wet grinding of various ores and other materials.It is widely used in mineral processing,cement and silicate products,new building materials,refractory materials,chemical fertilizers and glass ceramics and so on production industry.It is also widely used in mineral processing ,construction and chemical industry and other national economic departments.

Working principle of Energy-saving grid(overflow) Ball Mill

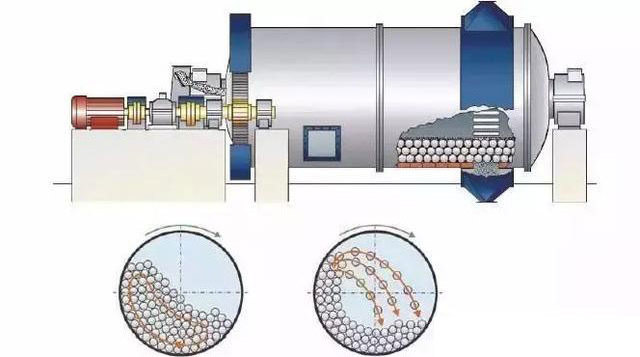

When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotates. When the barrel rotates, Steel balls or other grinding media in the barrel are lifted to a certain height and fall down freely, so materials in the barrel are impacted.

Grinding media mixing with materials impact and grind materials continuously. The grinding media and materials impact and grind each other when the ball mill rotates continuously. The final product will be discharged from outlet when it meets the request, so the grinding process is finished.

Specification of Energy-saving grid(overflow) Ball Mill

|

Model |

Cylinder RPM(r/min) |

Ball load (t) |

Feeding size (mm) |

Discharge size (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

| MQG600*1800 |

45.85 |

0.56 | ≤10 | 0.074-0.8 | 0.15-0.6 | 7.5 | 2 |

| MQG900*1800 | 38 | 1.8 | ≤25 | 0.075-0.6 | 0.4-2.7 | 22 | 5.5 |

| MQG900*3500 | 37.4 | 3 | ≤25 | 0.074-0.34 | 0.8-3.9 | 30 | 8 |

| MQG1200*2400 | 36 | 4.8 | ≤20 | 0.075-0.6 | 1.5-5.2 | 37 | 9.8 |

| MQG1200*4500 | 36 | 5.2 | ≤25 | 0.074 | 1.5-5.6 | 45 | 13.7 |

| MQG1300*4000 | 32 | 5.8 | ≤25 | 0.075-0.6 | 2-7.5 | 45 | 14.8 |

| MQG1500*3500 | 28.8 | 8.3 | ≤25 | 0.074-0.4 | 3.4-14 | 75 | 17.6 |

| MQG1500*4500 | 28.8 | 10 | ≤25 | 0.074-0.4 | 3.5-15 | 95 | 22.5 |

| MQG1500*5700 | 28.8 | 12 | ≤25 | 0.074-0.4 | 3.5-16 | 110 | 26.7 |

| MQG1500*6400 | 28.8 | 13 | ≤25 | 0.074-0.4 | 4-18 | 130 | 29.2 |

| MQG1830*3600 | 24.5 | 16 | ≤25 | 0.074-0.4 | 5.8-25 | 130 | 31.4 |

| MQG1830*4500 | 24.5 | 17.5 | ≤25 | 0.074-0.4 | 6.6-28 | 155 | 32.6 |

| MQG1830*7000 | 24.5 | 20 | ≤25 | 0.074-0.4 | 7.5-31 | 245 | 39.6 |

| MQG2100*3600 | 23.8 | 21 | ≤25 | 0.074-0.6 | 6-29 | 210 | 43.2 |

| MQG2100*4500 | 23.8 | 26 | ≤25 | 0.074-0.6 | 7.2-32 | 245 | 48.8 |

| MQG2200*7500 | 22.8 | 28 | ≤25 | 0.074-0.6 0 | 9-40 | 380 | 68 |

| MQG2400*3600 | 21.7 | 31 | ≤25 | 0.074-0.6 | 9-42 | 280 | 56 |

| MQG2400*9000 | 21.7 | 45 | ≤25 | 0.074-0.6 | 10-50 | 630 | 92 |

| MQG2700*3600 | 21.4 | 39 | ≤25 | 0.074-0.6 | 13-145 | 400 | 86 |

| MQG2700*4500 | 21.4 | 50 | ≤25 | 0.074-0.6 | 15-160 | 475 | 91 |

| MQG3000*5400 | 19 | 58 | ≤25 | 0.074-0.6 | 20-180 | 630 | 113.5 |

| MQG3200*3600 | 18.6 | 52 | ≤25 | 0.074-0.6 | 20-192 | 630 | 119 |

| MQG3200*4500 | 18.6 | 65 | ≤25 | 0.074-0.6 | 30-210 | 800 | 127 |

| MQG3200*5400 | 18.6 | 72 | ≤25 | 0.074-0.6 | 35-260 | 1000 | 145 |

| MQG3600*4500 | 17.3 | 88 | ≤25 | 0.074-0.6 | 30-230 | 1120 | 159.7 |

| MQG3600*5000 | 17.3 | 96 | ≤25 | 0.074-0.6 | 35-260 | 1250 | 165 |

| MQG3600*6000 | 17.3 | 117 | ≤25 | 0.074-0.6 | 38-280 | 1400 | 182 |

| MQG4000*6000 | 16.9 | 145 | ≤24 | 0.074-0.6 | 60-460 | 1500 | 216 |

| MQG4500*6000 | 15.6 | 180 | ≤24 | 0.074-0.6 | 80-550 | 2300 | 269.6 |

Shipping :we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Since founded more than 10 years ago, our company has accumulated much experience in the business of Ball Grinding Mill and ceramic ball mill.Welcome to visit our factory and would like to start the cooperation with you in the near future.