- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

TED

-

Weight:

-

4300 KG

-

Material:

-

304 Stainless Steel

-

Capacity:

-

300-1000 bph

-

Suit for:

-

Chicken Duck Goose Bird

-

Feature:

-

Customized Slaughter Line

-

keywords1:

-

slaughter machine

-

keywords2:

-

Chicken Slaughter Line

-

keywords3:

-

abattoir equipment for chicken

-

keywords4:

-

slaughterhouse

-

keywords5:

-

mobile slaughterhouse

-

keywords6:

-

mobile abattoir

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

zlzsen

-

Voltage:

-

380V, customermized

-

Dimension(L*W*H):

-

TED

-

Weight:

-

4300 KG

-

Material:

-

304 Stainless Steel

-

Capacity:

-

300-1000 bph

-

Suit for:

-

Chicken Duck Goose Bird

-

Feature:

-

Customized Slaughter Line

-

keywords1:

-

slaughter machine

-

keywords2:

-

Chicken Slaughter Line

-

keywords3:

-

abattoir equipment for chicken

-

keywords4:

-

slaughterhouse

-

keywords5:

-

mobile slaughterhouse

-

keywords6:

-

mobile abattoir

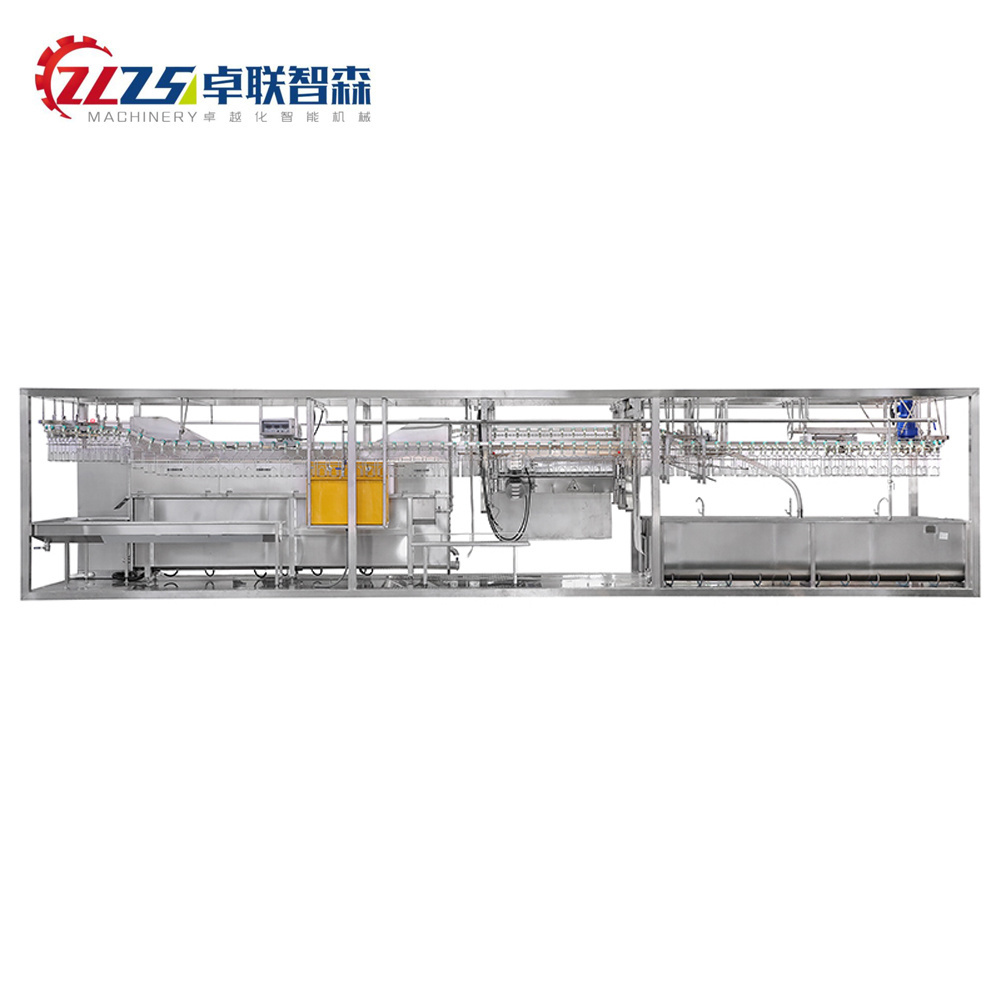

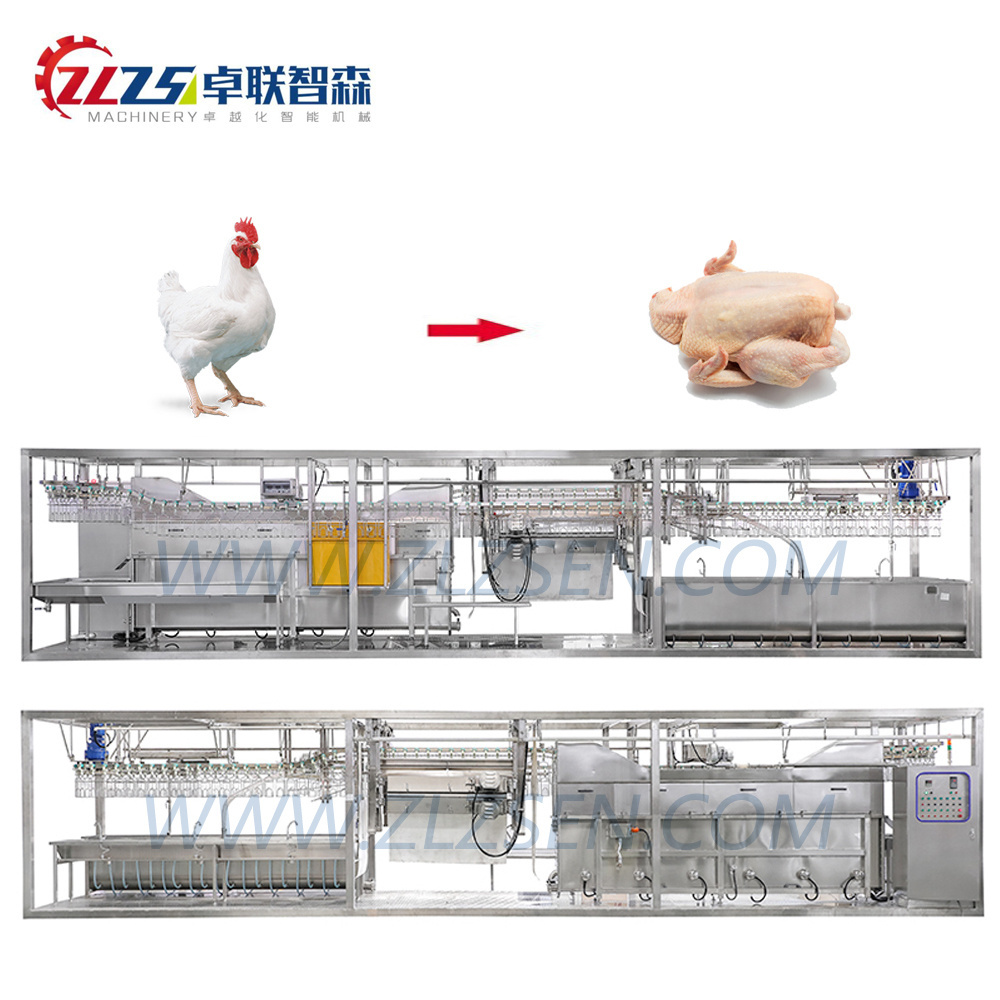

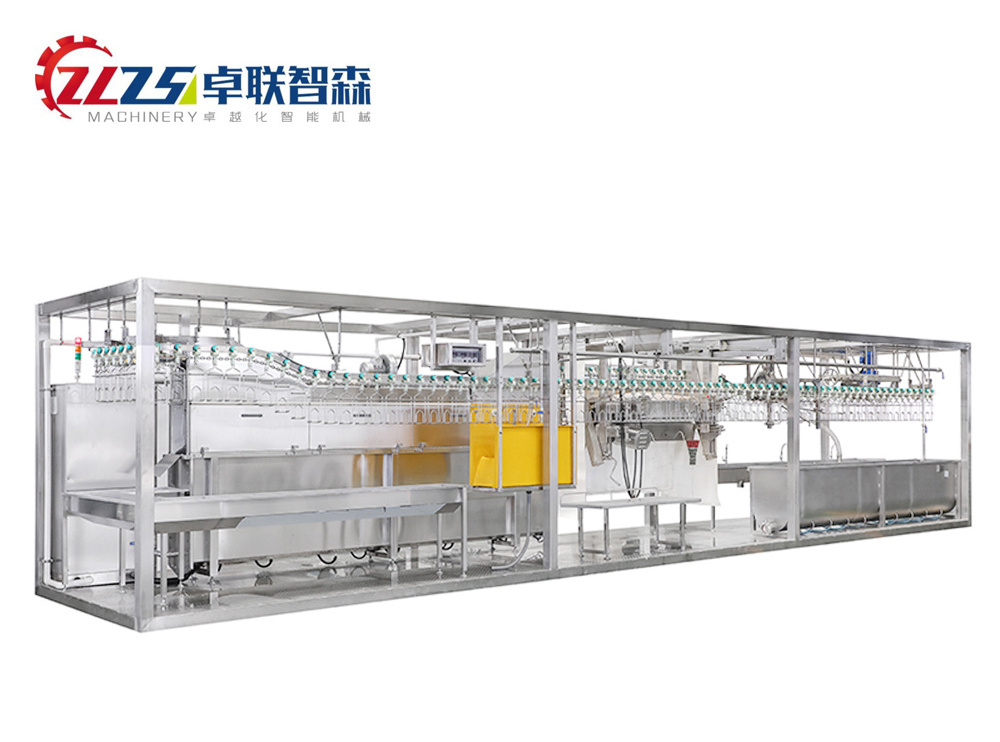

300-800BPH Chicken Slaughter Line

Video

Compact Movable Chicken Slaughter Line Advantages

|

Standard capacity is 300-800bph, new design can reach 1000bph, contact us for more info

|

|

|

|

|

||||

|

* 1.Convenient for shipping, only one 40HQ is needed

* 2.High strength 304 stainless steel ,Keep food safety and hygiene standards * 3.Installation completed before shipping. The equipment can be used directly on site. * 4.Easy operation & Labor-saving&Low energy consumption&Long effective service life * 5.Stable operation & increase the working efficiency,processing 500-1000 birds per hour * 6.Compact working space,Suitable for any work situation. |

|

|

|

|

||||

Slaughter Line Major Machines

STUNNING MACHINE

Electrical Stunner is designed to use electricity to let active live birds be quiet, which is essential for the effectiveness of

the future kill and bleed out processing. It’s also a better way to have animal welfare With the advantage of high efficiency,With the advantage of high efficiency,it is an ideal equipment for various poultry processing plant and factory.The structures includes, glass fibre reinforced plastic,electrical conductance system and main frame.The active birds, hung on the shackles, are moved to the water tank by the overhead conveyor The birds will be attacked by a sudden strong current when they are immersed into

the water.

BLEEDING TROUGH

The equipment structures includes main tank, frame, support and pipe. All parts are made of 304 stainless steel.

Bleeding Trough is set properly under the bleeding conveying line after the chicken is cut the neck and has blood out. It’s better to use to collect the clean blood and keep the bleeding area clean.

SCALDING MACHINE

Scalder is one of the major machine in the poultry processing industry. The water inside the scalding tank is heated by electric directly, agitating by air blower and supplied by auto water system during the operation. It offers a great performance for the next plucking processing to get a 99% plucking ratio for clean and perfect skin of the chicken body. It has the performance of easy operation,

The chicken carcasses hooked in the conveying line are conveyed in the scalding channel in certain speed,which make sure the enough scalding time.Automatic water supply system works to keep the chicken body immersed into the hot water. Heat system works to keep the water temperature. Agitating system works to keep water agitating in certain temperature by the air blower and agitating nozzle.The chicken carcasses go through the agitated water and air, to have feathers and body being scalded totally.

good reliability, small noise and is greatly suitable for various chicken slaughterhouse.

The chicken carcasses hooked in the conveying line are conveyed in the scalding channel in certain speed,which make sure the enough scalding time.Automatic water supply system works to keep the chicken body immersed into the hot water. Heat system works to keep the water temperature. Agitating system works to keep water agitating in certain temperature by the air blower and agitating nozzle.The chicken carcasses go through the agitated water and air, to have feathers and body being scalded totally.

PLUCKING MACHINE

Plucker is mainly used for feather removing in the production of poultry processing.It mainly consists of power

transmission device, cabinets adjustment device,water spraying and guiding device. It is equipped with plucking cabinets on each side, simple and easy adjustment in height,width and rotation individually. Flexible speed in operation to the minimum of incidental damage to the skin of the birds Optional numbers of the driven plucking disc per the capacity of the plant.

transmission device, cabinets adjustment device,water spraying and guiding device. It is equipped with plucking cabinets on each side, simple and easy adjustment in height,width and rotation individually. Flexible speed in operation to the minimum of incidental damage to the skin of the birds Optional numbers of the driven plucking disc per the capacity of the plant.

During the running of conveying line, birds body will be taken into Plucker’s cabinets by the hooks of the conveying line, and the upper guide device will hold the hooks and birds body at the certain place. There are many rotating discs equipped with plucking fingers in the cabinets, and every two adjacent rotating discs are running in opposite directions. Then during the mechanical drive of machine,the relative motion between the bird body and the rubber plucking finger will help to remove bird feather.

EVISCERATION TROUGH

Evisceration Trough is set to take the giblets and store it. It’s designed with slope, water valve and water pipe to clean the giblets as soon as they are taken out from the chicken body.

It includes trough body and frame / water valve / water pipe.

It includes trough body and frame / water valve / water pipe.

Evisceration Trough is set properly under the evisceration conveying line where the chicken giblet is taken out from its

cavity. It’s better to collect the giblet in a safety and clean condition.

cavity. It’s better to collect the giblet in a safety and clean condition.

PRE-CHILLING TANK

Pre-chilling tank is used for Poultry processing line, the purpose is washing the chicken carcass & decrease the carcass temperature.

It includes main body and air blowing systerm.

The carcass are dropped from the conveying line into the pre-chilling tank,the air agitating system will agitate the water and carcasses to get a much better chilling performance. Another design, it can be replaced by a spiral pre-chiller, which is more efficient.Contact us for more info.

It includes main body and air blowing systerm.

The carcass are dropped from the conveying line into the pre-chilling tank,the air agitating system will agitate the water and carcasses to get a much better chilling performance. Another design, it can be replaced by a spiral pre-chiller, which is more efficient.Contact us for more info.

Details Images

Recommend Products

Packing And Delivery

Contact

Hot Searches