Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Raw material:

-

Pvc Powder+wood Powder+ Additives

-

Inverter:

-

ABB for wood plastic composite production line

-

Contactor:

-

France SCHNEIDER Contactors

-

Final product:

-

Wood Plastic Composite Products

-

Motor:

-

Germany SIEMENS Motor

-

Machine type:

-

PVC Plastic Profile Machine

-

Output:

-

150-450 kg/h for wood plastic composite production line

-

Temperature controller:

-

Omron Brand

-

Power(W):

-

37-132 Kw

-

Output (kg/h):

-

200 - 550

-

Certification:

-

CE&ISO9001

Quick Details

-

Screw Design:

-

Double-screw

-

Screw diameter (mm):

-

65 mm

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Raw material:

-

Pvc Powder+wood Powder+ Additives

-

Inverter:

-

ABB for wood plastic composite production line

-

Contactor:

-

France SCHNEIDER Contactors

-

Final product:

-

Wood Plastic Composite Products

-

Motor:

-

Germany SIEMENS Motor

-

Machine type:

-

PVC Plastic Profile Machine

-

Output:

-

150-450 kg/h for wood plastic composite production line

-

Temperature controller:

-

Omron Brand

-

Power(W):

-

37-132 Kw

-

Output (kg/h):

-

200 - 550

-

Certification:

-

CE&ISO9001

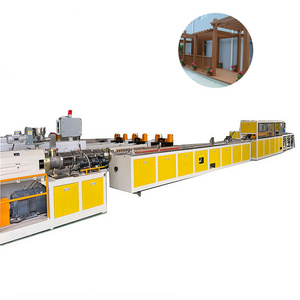

wood pellet production line/plastic wood composite making machine/wood plastic composite production line

Raw materials used in manufacturing:

PVC material + plant fiber(wood power, rice chaff etc)+necessary chemical ingredient

Process flow:

1. Wood > Wood powder > (wood flour dryer)

2. PVC material + wood flour + necessary ingredient > WPC mixing equipments-- > WPC board Extrusion Line -- >WPC board profile-hot transfer printing -- > final door board

1. It can produce PE, PP or PVC wood-plastic of by applying specially designed screw, material cylinder, mold and processing production technology and auxiliary machines for shaped material, the line is Wood-plastic Extruding Production Line.

2.it may produce PE, PP or PVC wood-plastic different shaped products.

The wooden-plastic mixing extruding production line adopts special-designed screw stem, material cylinder, moulds and processing technology.

3.Equipped with YE model auxiliary it can produce wooden-plastic profile. It is a new kind of environment protection products which Mix plastic and waste wood fiber in proper proportion, adding plastic processing extender.

4.It can produce, package box plate, frame material for door and window, floor board, outside products extruded in high temperature and high pressure

wood-plastic extruder line. wood-plastic extruding line. wood-plastic production line

APPLICATION

- General wall and ceiling decoration

- Places where classy decor is required included hotels, office buildings, lobbies, shops and restaurants

- Wall partitioning and ceiling conversion

- Feature walls

- Place where high sanitary and easy maintenance is required including factories, schools, child care centers, hospitals and pubic areas.

- Damp areas including bathrooms, laundry rooms, basements and toilets

|

Model |

Max.wide (mm) |

Extruder model |

Max.output (kg/h) |

Motor power(kw) |

|

YF108 |

108 |

SJZ51/105 |

150 |

18.5 |

|

YF180 |

180 |

SJZ51/105 |

150 |

18.5 |

| YF180 | 180 |

SJZ55/110 |

190 |

22 |

|

YF240 |

240 |

SJZ65/132 |

250 |

37 |

|

YF300 |

300 |

SJZ80/156 |

250 |

37 |

|

YF400 |

400 |

SJZ80/156 |

350 |

55 |

|

YF500 |

500 |

SJZ80/156 |

350 |

55 |

|

YF600 |

600 |

SJZ80/156 |

400 |

75 |

Zhangjiagang Sevenstars Machinery Co.,Ltd. was founded in 2006. it is an enterprise specialized in producing plastic machinery.it lies to the south of the middle and lower reches of Yangtze River.It is located in the National civilization and hygienic city-zhangjiagang , Surrounded by the economic belt of Suzhou,Wuxi,Changzhou,Nanjing and Shanghai.Both land and river transports are rather convenient.We sell our products to Europe middle,Africa and Asia,etc country and region.Our products enjoy a high reputation home and abroad.

1.Upon request Supplier will dispatch engineers to install the machines and do commissioning together with customer’s workers.

2.Meanwhile, engineers will teach how to operation, maintain for buyer’s engineers, worker on site.

3.We also offer long term technical guidance.

1.How about the quality about this machine?

Answer: yes,my friend,please rest assured,we have nearly 10 years experience for this machine.quality is no problem.

2.How about the output about this machine?is the data real?

Answer: my friend,we have tested that machine many times,then get this data,it is real and can meet your need.

3.Wether you deliver in time?

Answer: sure,once we receive your payment, then delivery immediately.

4.What about your after service?

Answer: we can send our engineers to you factory and offer long term technical guidance.

WELCOME TO INQUIRY US , MANY THANKS !