Waste Tire Recycling Rubber Granule Making Machine is adopting physical recycling method and is designed to grind the rubber mulch from the rasper into small granules as fine as 1-6mm. The granules are screened and re-circulated until the desired size is reached. This Fully-Automatic Tyre Recycling Line running in normal temperature, no need to add any other chemicals, no pollution to the environment. This is the best way to recycling scrap tires.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HVST-M1000

-

Voltage:

-

as clients local requets

-

Weight (KG):

-

30000 kg

-

After-sales Service Provided:

-

Free spare parts

-

Raw material:

-

TIRE SHREDDER

-

Application:

-

Rubber Processing Machinery

-

Function:

-

Tire Powder Recycling Machine

-

Product name:

-

Automatic scrap tire recycling rubber powder processing line price

-

final size:

-

50mm/ 10-30 mm/1-7mm/40-120mesh

-

Capacity:

-

1 ton per Hour

-

Usage:

-

grind the tire into rubber powder

-

End product:

-

rubber block, rubber mulch, rubber granules and rubber powder

-

Output:

-

30-120mesh

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

HVST

-

Marketing Type:

-

New Product 2023

-

Model Number:

-

HVST-M1000

-

Voltage:

-

as clients local requets

-

Weight (KG):

-

30000 kg

-

After-sales Service Provided:

-

Free spare parts

-

Raw material:

-

TIRE SHREDDER

-

Application:

-

Rubber Processing Machinery

-

Function:

-

Tire Powder Recycling Machine

-

Product name:

-

Automatic scrap tire recycling rubber powder processing line price

-

final size:

-

50mm/ 10-30 mm/1-7mm/40-120mesh

-

Capacity:

-

1 ton per Hour

-

Usage:

-

grind the tire into rubber powder

-

End product:

-

rubber block, rubber mulch, rubber granules and rubber powder

-

Output:

-

30-120mesh

waste tire shredding recycling machine in rubber powder line tire recycling equipment price

Feature

The pre-grinding system can be equipped with bolt cutting tools to minimize operating costs and simplify line maintenance.

The two-stage rasper system effectively releases steel from the rubber for efficient separation and clean line production.

The fine granulation system is equipped with a special rotor specially designed to reduce the rubber size of the tire. It provides maximum throughput while minimizing the amount of fines generated. The machine is also optimized for low operating and wear costs.

Inhale textiles and dust at several locations in the recycling system.

The central reverse jet filtration system extracts dust from the entire system.

Our milling system can be installed at the rear of the tire recycling system. The size and configuration of the milling system is configured according to specific production requirements, ie size and throughput.

An advanced sound attenuating enclosure is available to reduce the noise level of the system to <85dBA.

Water spray and atomization systems are installed on critical components to keep process temperatures safe and prevent fires.

System automation ensures component operation links, maximizes system capacity, and best protects the system from interfering materials.

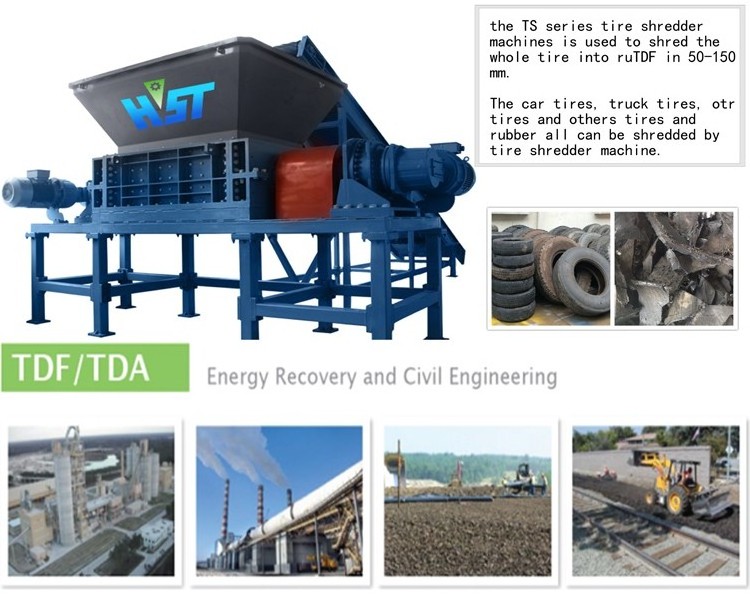

1.Tire shredder machine

The Rubber Shredder Machine adopt PLC automatic control system, with automatic reversal control system in overload condition. Two-shaft tire crusher is specially designed for old tires with low speed and high torque to minimize noise and power consumption.

The blade of the shredder is made of high quality steel and subjected to Bodycote heat treatment to achieve the best crushing performance.The shredder is easy to disassemble and change cutter blade and suitable for tearing large, extra thick and hard materials.The thickness range of the crushing blade is 25mm-152mm according to the tire type,output and final product. The grinder can process OTR tires,big truck tires,car tires and so on at the speed of 1-30tons whithin 1 hour.

|

Model

|

Input size

|

Output size

|

Cappacity

|

Motor

|

Blades quantity

|

Dimensions

|

Weight

|

|

TS-800

|

800mm

|

50*50mm

|

1-2T/h

|

2*22kw

|

16pcs

|

4*2.6*3.2m

|

8T

|

|

TS-1200

|

1200mm

|

60*60mm

|

3-5T/h

|

2*37kw

|

20pcs

|

4.8*2.8*3.5m

|

14T

|

|

TS-1600

|

1600mm

|

50-150mm

|

6-8T/h

|

2*45kw

|

16-30pcs

|

5*2*3.4m

|

18T

|

|

TS-1800

|

1800mm

|

50-150mm

|

7-10T/h

|

2*55kw

|

20-24pcs

|

5.6*2*3.4m

|

23T

|

|

TS-2000

|

2000mm

|

75-200mm

|

10-15T/h

|

2*75kw

|

20-30pcs

|

6*2.4*4m

|

36T

|

|

TS-2400

|

2400mm

|

100-200mm

|

20-30T/h

|

2*110kw

|

16-24pcs

|

7.4*3.2*5.2m

|

56T

|

2.Rasper

HVST tire shredding system is designed to produce up to 6 tons per hour of wire free rubber mulch.This system produces up to a 99% wire free chip ranging in size between 12-25mm depending on the desired size.After processing,the steel is removed by our magnetic separation system.At this point,the wire free rubber chips are ready to be colored and used for landscaping mulch and the steel is ready to be baled and sold to smelters.

|

Rasper

|

Motor

|

Power

|

Capacity

|

Dimensions

|

Weight

|

Cutting chamber

|

Final product

|

|

R45

|

Siemens

|

45KW

|

300-500kg/H

|

1.4*1.2*2.3m

|

1700kg

|

450*600mm

|

10-30mm

|

|

R55

|

Siemens

|

55KW

|

500-700kg/H

|

1.7*1.7*2.3m

|

1850kg

|

450*800mm

|

10-30mm

|

|

R75

|

Siemens

|

75KW

|

700-1T/H

|

2*2*4.1m

|

3500kg

|

550*800mm

|

10-30mm

|

|

R90

|

Siemens

|

90KW

|

1-1.5T/H

|

2.1*2.1*4.1m

|

4200kg

|

550*1000mm

|

10-30mm

|

|

R132

|

Siemens

|

132KW

|

1.5-3T/H

|

2*2.5*4.1m

|

6100kg

|

742*1200mm

|

10-30mm

|

|

R315

|

Siemens

|

315KW

|

3-6T/H

|

6.2*2.1*3.6m

|

12400kg

|

697*1562mm

|

10-30mm

|

3.Granulator machine

|

Granulator

|

G37

|

G45

|

G90

|

|

Motor

|

Siemens

|

Siemens

|

Siemens

|

|

Power

|

37kw

|

45kw

|

90kw

|

|

Capacity

|

300-500kg/h

|

500-800kg/h

|

800-1500kg/h

|

|

Dimensions

|

1.8*1.6*2.4m

|

1.8*1.9*2.4m

|

2.2*2.3*3m

|

|

Final product

|

1-6mm

|

1-6mm

|

1-6mm

|

4.Miller

Rubber powder is the final result of ambient tire recycling.At this stage,crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.Rubber powder has numerous secondary uses from injection molding products,coatings,roofing materials and various asphaltapplications.

Rubber powder is typically found in 40-74 microns(0.40-0.74mm) in size.This micron size metarial has the advantage of being incorporated into new or existing formulations for various polymers and finished products.

|

Rubber powder

|

M2000

|

M1500

|

M1000

|

M500

|

|||

|

Input product

|

Heavy duty truck tyres to bicycle tyres

|

|

|

|

|||

|

Input size

|

Diameter 1800mm

|

Diameter 1800mm

|

Diameter 1800mm

|

Diameter 1800mm

|

|||

|

Output size

|

shred to 30-120 mesh rubber powder

|

|

|

|

|||

|

Capacity

|

2000kg/h

|

1500kg/h

|

1000kg/h

|

500kg/h

|

|||

|

Total Kw

|

680-760kw

|

516-556kw

|

347-372kw

|

170-190kw

|

|||

ZHENGZHOU HARVEST MACHINERY CO.,LTD

Zhengzhou Harvest Machinery Factory was established in 1987,it's one of the earliest professional manufacturers of nail making machine and tire recycling machines.With advanced production experience,first-class management technology and the professional after-sale service team,our products not only occupythe domestic market, but also export overseas continuously,which has received unanimous praise from our clients.Our factory always aims to put customers' needs at first place,and has consistently tried to upgrade its products for more than 20 years. The main products now , nail making machine and tire recycling production line , have already obtained good market for their high quality and reliable technology.