- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

guolian

-

Outer Diameter:

-

1 - 500 mm

-

Thickness:

-

32mm

-

Grade:

-

stainless steel

-

Material:

-

Carbon steel tube Q235 Q345

-

Process Method:

-

automatic shape etc

-

Shape:

-

Round Section

-

Type:

-

Seamless

-

Steel Grade:

-

300 Series

-

Welding Line Type:

-

Seamless

-

Technique:

-

Hot Rolled , Cold Rolled

-

Payment::

-

L/C,T/T

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±5%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by theoretical weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

guolian

-

Outer Diameter:

-

1 - 500 mm

-

Thickness:

-

32mm

-

Grade:

-

stainless steel

-

Material:

-

Carbon steel tube Q235 Q345

-

Process Method:

-

automatic shape etc

-

Shape:

-

Round Section

-

Type:

-

Seamless

-

Steel Grade:

-

300 Series

-

Welding Line Type:

-

Seamless

-

Technique:

-

Hot Rolled , Cold Rolled

-

Payment::

-

L/C,T/T

Product Description

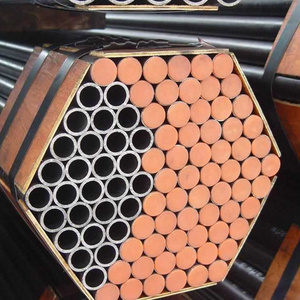

The seamless steel pipe

is made of perforated whole round steel, and the steel pipe without weld seam on the surface is called seamless steel pipe. According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, and pipe jacking. According to the cross-sectional shape, the seamless steel pipe is divided into two types: round and special-shaped. The maximum diameter is 900mm and the minimum diameter is 4mm. According to different uses, there are thick-walled seamless steel pipes and thin-walled seamless steel pipes. Seamless steel pipes are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemical industries, boiler pipes, bearing pipes and high-precision structural steel pipes for automobiles, tractors and aviation.

Specification

|

Material:

|

Q355b Q235 Q345 and others

|

|

Customized

|

Yes

|

|

Weight measurement

|

tons

|

|

Shipping method:

|

By sea

|

|

Goods property:

|

spot

|

|

Quality grade:

|

A

|

|

Specifications:

|

273*12mm

|

|

Nature of goods:

|

wholesale,retail

|

|

Surface treatment:

|

anti-corrosion,anti-rust

|

|

Application:

|

Steel structure,fluid

|

|

Features:

|

Seamless

|

|

Material properties:

|

High strength

|

Seamless carbon steel pipes are made of steel ingots or solid billets through perforation to make capillaries, which are then hot-rolled, cold-rolled or cold-drawn. Seamless carbon steel pipe plays an important role in my country's steel pipe industry. According to incomplete statistics, there are more than 240 seamless carbon steel pipe manufacturers in my country, more than 250 sets of seamless carbon steel pipe units, and an annual production capacity of about 4.5 million tons. From the perspective of diameter, <φ76, accounting for 35%, <φ159-650, accounting for 25%. In terms of varieties, general-purpose pipes are 1.9 million tons, accounting for 54%; oil pipes are 760,000 tons, accounting for 5.7%; hydraulic struts and precision pipes are 150,000 tons, accounting for 4.3%; stainless pipes, bearing pipes, and automobile pipes total 50,000 tons. tons, accounting for 1.4%.

The raw material of seamless carbon steel pipe is a round tube blank, which is cut by a cutting machine into a billet with a length of about 1 meter, and sent to a furnace for heating through a conveyor belt. The billets are fed into the furnace and heated at about 1200 degrees Celsius. The fuel is hydrogen or acetylene. Furnace temperature control is a critical issue. After the round tube blank is released from the furnace, it is pierced through a pressure punching machine. Generally, the more common punching machine is the conical roller punching machine. This kind of punching machine has high production efficiency, good product quality, large amount of perforation and diameter expansion, and can wear a variety of steel grades. After perforation, the round tube blank is successively cross-rolled, continuously rolled or extruded by three rolls.

1. Seamless steel pipe for structure (GBT8162-2008). Mainly used for general structure and mechanical structure. Its representative material (brand): carbon steel, 20, 45 steel; alloy steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, etc.

2. Seamless steel pipes for conveying fluids (GBT8163-2008). It is mainly used for conveying fluid pipelines in engineering and large-scale equipment. The representative material (grade) is 20, Q345, etc.

3. Seamless steel pipes for low and medium pressure boilers (GB3087-2008) are used to manufacture various structures of low and medium pressure boiler superheated steam pipes, boiling water pipes and superheated steam pipes, large smoke pipes, small smoke pipes and arch bricks for locomotive boilers Hot-rolled and cold-drawn (rolled) seamless steel pipes of high-quality carbon structural steel for pipes. The representative material is 10, 20 steel.

Shipping

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Production process

①The main production process of hot-rolled seamless steel pipe (△main inspection process):

Tube blank preparation and inspection△→tube blank heating→piercing→tube rolling→steel reheating→fixed (reduced) diameter→heat treatment△→finished pipe straightening→finishing→inspection△ (non-destructive, physical and chemical, Taiwan inspection)→warehousing

②The main production process of cold-rolled (drawn) seamless steel pipe:

Billet preparation→pickling lubrication→cold rolling (drawing)→heat treatment→straightening→finishing→inspection

s.

Hot Searches