- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

DAFANG

-

Voltage:

-

380V

-

Power:

-

5kw

-

Dimension(L*W*H):

-

970*600*1200mm

-

Weight:

-

1500 kg

-

Features:

-

Hollow core slab machine

-

Product name:

-

Floor slab machine

-

Keywords:

-

Prestressed Concrete Hollow Slab Forming Machine

-

Usage:

-

Precast Buildings

-

Finished products:

-

Hollow Slab

-

Color:

-

Customised

-

Raw materials:

-

Cement Sand Stone Concrete

-

Slab width:

-

600mm

-

Characteristics:

-

Fast Production

-

Panel Thickness:

-

90/120/180mm

-

Advantages:

-

Longer Working Time

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Construction works

-

Production Capacity:

-

70-90m/h

-

Place of Origin:

-

China

-

Brand Name:

-

DAFANG

-

Voltage:

-

380V

-

Power:

-

5kw

-

Dimension(L*W*H):

-

970*600*1200mm

-

Weight:

-

1500 kg

-

Features:

-

Hollow core slab machine

-

Product name:

-

Floor slab machine

-

Keywords:

-

Prestressed Concrete Hollow Slab Forming Machine

-

Usage:

-

Precast Buildings

-

Finished products:

-

Hollow Slab

-

Color:

-

Customised

-

Raw materials:

-

Cement Sand Stone Concrete

-

Slab width:

-

600mm

-

Characteristics:

-

Fast Production

-

Panel Thickness:

-

90/120/180mm

-

Advantages:

-

Longer Working Time

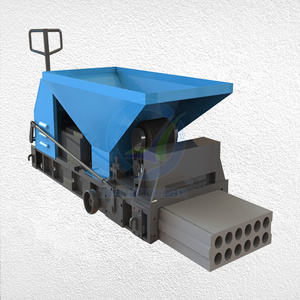

Roof Production Line Wall Panel Slab Extruder Machine Hollow Core Slab Fence Wall Making Precast Wall Panel Machine

Product Description

|

Product name

|

Prestressed concrete slab machine

|

|

|

||

|

Model

|

90*600

|

120*600

|

180*600

|

||

|

Width (mm)

|

600

|

600

|

600

|

||

|

Backness (mm)

|

90

|

120

|

180

|

||

|

Number of holes/diameter (mm)

|

7 Hole

|

5Hole

|

3Hole

|

||

|

Plate-making speed (m/min)

|

>1.8

|

>1.8

|

>1.8

|

||

|

Main motor (kw)

|

5.5KW

|

5.5KW

|

5.5KW

|

||

|

Vibrator (kw)

|

ZW5A-0.8

|

ZW5A-0.8

|

ZW5A-1.1

|

||

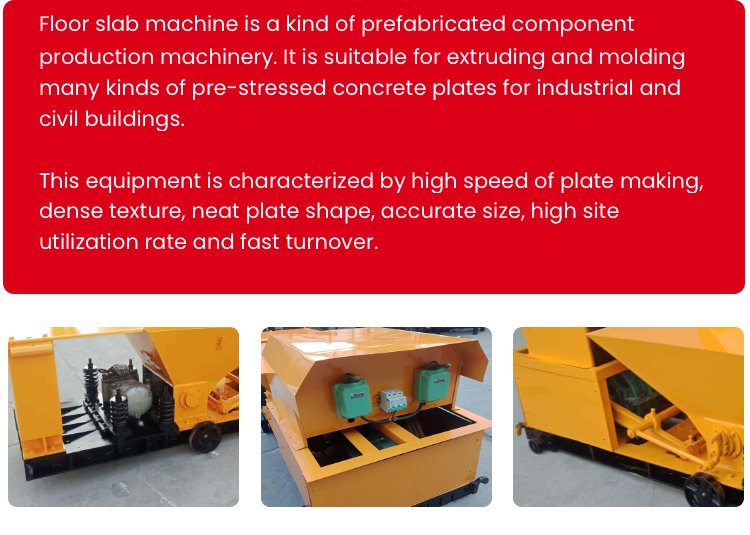

Concrete plate machine

Features:

1, s

imultaneous production of 4-6 hollow, solid, reinforced and non-reinforced cement products

2, than pulling the mold, demolding and other methods of production efficiency can be increased by 3-5 times.

3, vibrator characteristics: the use of good vibrators, vibration force, smooth operation, continuous operation without failure.

4, motor characteristics: ad hoc explosion-proof motor, power standards, smooth operation.

5, produced a variety of concrete components of good strength, good quality, smooth surface, geometric dimensional accuracy.

Working principle of floor forming machine

Push the extruded floor molding machine is working on the concrete platform, it uses the pre-stressing steel bars to do the guidance, the power of the motor through the reducer deceleration drives the connecting rod reciprocating motion, through the push plate, push the material will be free falling in the silo of the concrete material squeezed into the mold channel, combined with the upper part of the vibrator's vibration force, extrusion vibration molding, and at the same time, using the back of the push back of the material of the reaction force, so that the whole machine to overcome the friction with ground contact, along the prestressing steel bars, intermittent walking forward, behind the machine will be formed by the regularity of the pre-fabricated products, and then by the curing and maintenance of the length of the cut to the finished product according to the requirements of the length of the finished product.

Hot Searches