- Product Details

- {{item.text}}

Quick Details

-

Max. Tube Contracting Length (mm):

-

150

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Taikang

-

Year:

-

2022

-

Power (kW):

-

7

-

Weight (KG):

-

2380

-

Power:

-

Hydraulic

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Function:

-

Flaring Machine

-

Application:

-

Metal Pipe Processing

-

Control:

-

Touch Screen

-

Usage:

-

Copper Pipe Expander

-

Capacity:

-

40mm Pipe

-

Type:

-

Automatic Tube Shrink Machine

-

Tube Material:

-

Steel Copper Aluminium

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

2 mm

-

Max.Shrinking Capacity (Diameter)(mm):

-

40 mm

-

Tube Contracting Cycle (s):

-

3 - 5

-

Max. Tube Contracting Length (mm):

-

150

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Taikang

-

Year:

-

2022

-

Power (kW):

-

7

-

Weight (KG):

-

2380

-

Power:

-

Hydraulic

-

Certification:

-

ce

-

After-sales Service Provided:

-

Online support

-

Function:

-

Flaring Machine

-

Application:

-

Metal Pipe Processing

-

Control:

-

Touch Screen

-

Usage:

-

Copper Pipe Expander

-

Capacity:

-

40mm Pipe

-

Type:

-

Automatic Tube Shrink Machine

-

Tube Material:

-

Steel Copper Aluminium

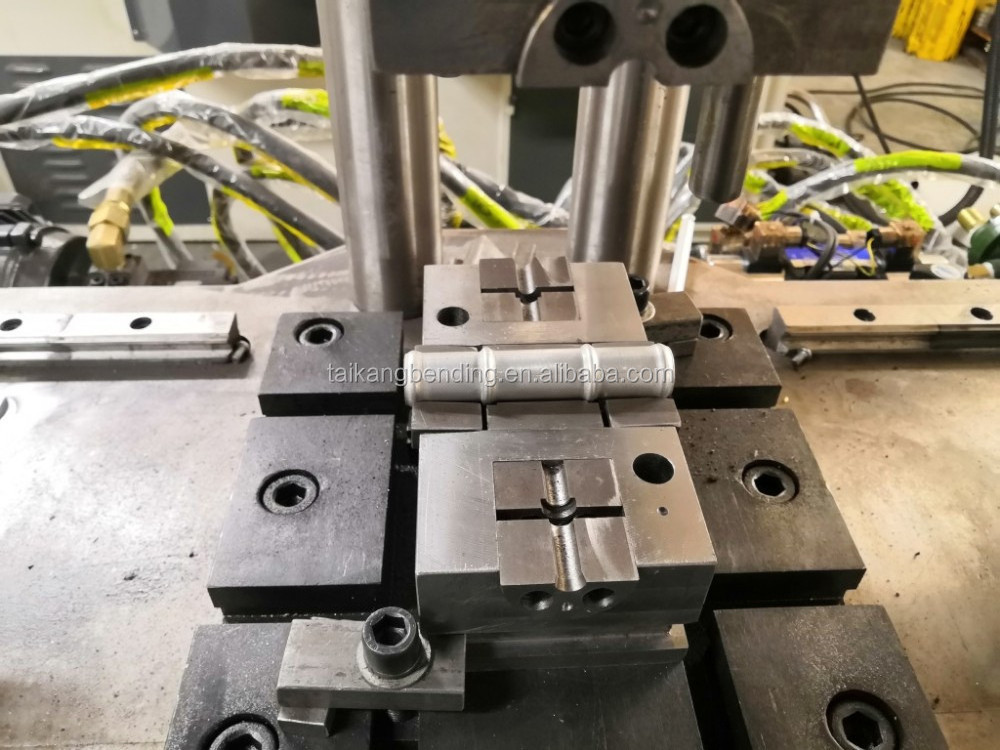

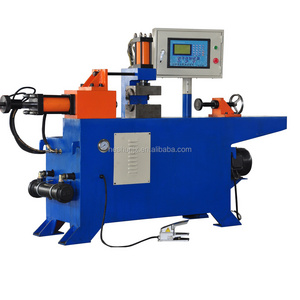

Product Application

SM20TNC double head pipe tube end forming machine pipe end forming machine pipe shrink expansion end forming machine uses linear guide rail as carrier to make the operation wear-free and the product repeatable. It is suitable for end treatment of Brass / Copper, Stainless Steel, Aluminum, Aluminium Alloy, Carben steel pipe and solid bars. It was widely used in mass production of pipe end shrinkage, diameter expansion, bulging, upsetting, flanging, and other shapes. It is suitable for various shapes of pipe end connection, automobile oil pipe, air pipe, water pipe, air conditioning pipe, connection parts and etc.. with high efficiency.

SM20TNC double head pipe tube end forming machine pipe end forming machine pipe shrink expansion end forming machine

Main Features

1) The Automatic Double-head and double-position pipe end forming machine, controlled by micro-computer, can work independently at both ends or simultaneously, with high production efficiency and good product stability.

2) Imported hydraulic valve components with high performance .3) Equipped with large capacity cooling system to control working temperature effectively .

4) Manual and semi-automatic operation mode can be chosen . Mobile pedal switch has two functions of starting and stopping.

5) It can be used for pipe end shrinkage, diameter expansion, bulging, upsetting, flanging, and other shapes. It is suitable for various shapes of pipe end connection, automobile oil pipe, air pipe, water pipe, air conditioning pipe, connection parts and etc..

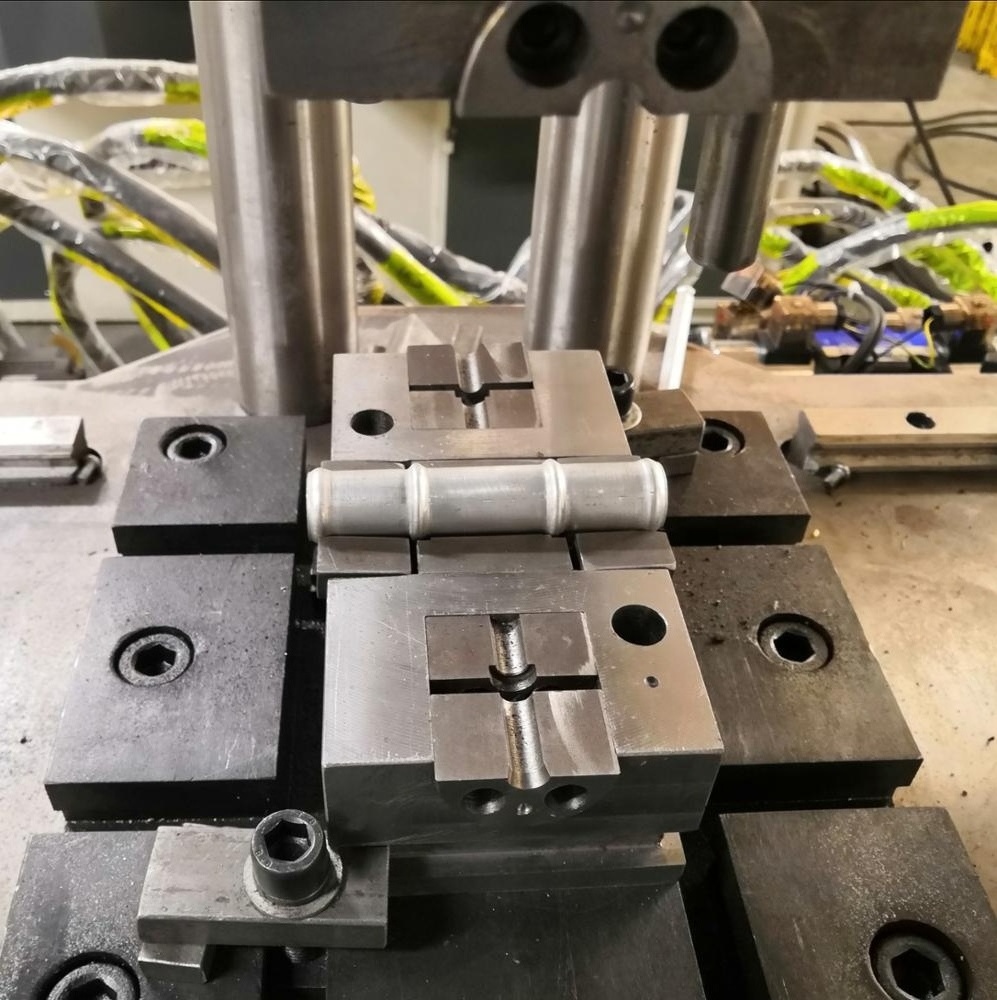

Machine Parts

Name: Hydraulic cylinder

20Ton strong force suitable for different mould

Machine Parts

Name:

Solenoid valve

Made in Taiwan famous brand, accurate and high reliablity

Machine Parts

Name:

Pressure Buffering device

Powerfull hydraulic motor and pressure buffering device to ensure stable hydraulic pressure and synchronization

Universal mould.

Tailor made combination design to meet requirement of your different products

Pre-Sales Service

* Inquiry and consulting support.

*Provide technical suggestion and package solution

* Sample testing support.

*Reply within 24 hours

*Provide progress information

* View our Factory.

After-Sales Service

*Test the machine before shipment

* Provide technical training relate to use the machine.

* Engineers available to service machinery overseas.

* Free spare parts within one-year warranty period

* Reasonable price for spare parts after warranty

* Provide long-term technical assistance.

A bout our company.

Suzhou TaiKang Machinery Co.,Ltd. Founded 2015.One of top manufacturer in China.Specializing in design and manufacturermachines for pipe process equipment and

tailor made solutions for the global supplier.

Our business philosophy is Client First,Quality First and Honesty First. We sincerely welcome worldwide potential buyers and overseas distributors to contact and visit us for cooperation.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate