- Product Details

- {{item.text}}

Quick Details

-

Production Capacity (kg/h):

-

300 - 1000 kg/h

-

Brand Name:

-

RUILI

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

55m*15m*6m

-

Power (kW):

-

78

-

Weight (T):

-

10

-

Product name:

-

PP PE soft plastic recycling machine line

-

Application:

-

Recycling PP PE plastic

-

Type:

-

Crushing and washing

-

Lifetime:

-

More than 5 years

-

Capacity:

-

0.3-1t/h

-

Keyword:

-

Waste recycling machine

-

Function:

-

Plastic Recycling Process

-

Other name:

-

PP PE washing machine line

-

Suitable material:

-

PP PE soft plastic

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Max.Production Capacity (kg/h):

-

1000

-

Place of Origin:

-

Hubei, China

-

Machine Type:

-

Plastic recycling machine

-

Production Capacity (kg/h):

-

300 - 1000 kg/h

-

Brand Name:

-

RUILI

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

55m*15m*6m

-

Power (kW):

-

78

-

Weight (T):

-

10

-

Product name:

-

PP PE soft plastic recycling machine line

-

Application:

-

Recycling PP PE plastic

-

Type:

-

Crushing and washing

-

Lifetime:

-

More than 5 years

-

Capacity:

-

0.3-1t/h

-

Keyword:

-

Waste recycling machine

-

Function:

-

Plastic Recycling Process

-

Other name:

-

PP PE washing machine line

-

Suitable material:

-

PP PE soft plastic

-

After-sales Service Provided:

-

Video technical support

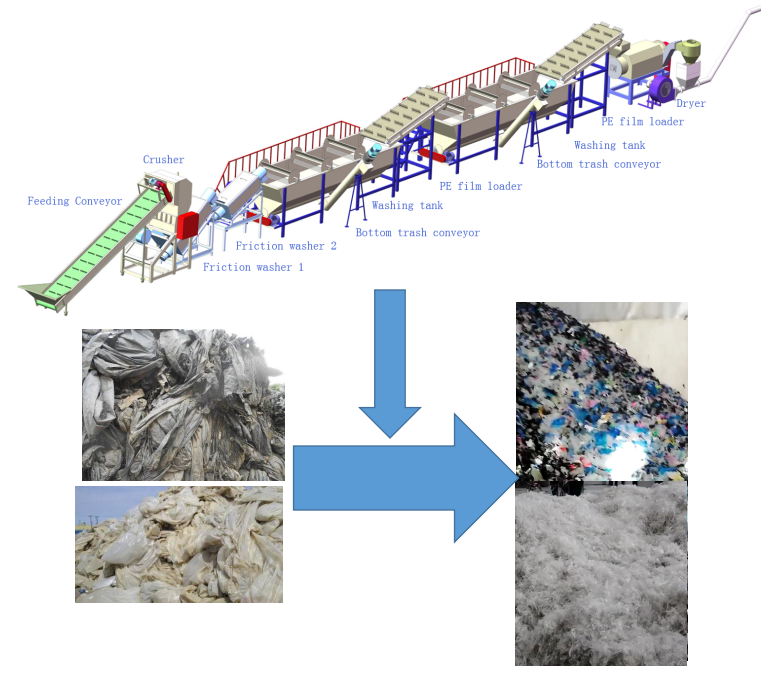

Agricultural plastic pp pe film washing machine recycling line

Plastic film washing line

This is widely used to treat waste PP woven bags, PE Plastic film,plastic bags, plastic garbage, waste plastic mulch film,nylon film. It is a crushing, washing, drying line. This production line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. This film recycling machine could be displayed "L" or "U" shape according clients' workshop.

Technical Parameters, for reference:

|

Input capacity |

500kg/h |

1000kg/h |

2000kg/h |

|

Workshop (m) |

35(L)*10(W)*6(H) |

45(L)*10(W)*6(H) |

55(L)*15(W)*6(H) |

|

Ancillary staff |

4 persons |

6 persons |

8 persons |

|

Installation power |

100kw |

160kw |

200kw |

|

Water consumption |

2 t/h |

3 t/h |

4 t/h |

|

Final product |

20mm Clean HDPE Flakes Moisture:max1% Metal content: max20ppm Floatable contamination: less than 200ppm Total impurity: 250ppm |

||

Featured with:

1. Strong structure, easy to operate, low electricity consumption & durable.

2. Uses high quality steel material especially for making knives of the crushers, the machine stands long use under severe and continuous service conditions.

3. The blades can be ground for many times and can be used repeatedly; Blades base structure is stable and durable.

4. Special design for PE/PP film, woven bags, fishnet, safety net and other soft strip plastic.

5. Water can be added during crushing, to increase the service life of the blade, and the bottle pieces can be cleaned preliminarily.

6. Has protection system with the power supply to ensure the equipment safe.

7. Easy to clean and maintain, the hopper, crusher room, blades and screen can be removed and mounted easily.