- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200KG-2000KG

-

Certification:

-

CE, ISO, SGS

-

Name:

-

TONSEN ethanol plant winery used distillery equipment

-

Application:

-

Beer equipment

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

50-10000L

-

Heating method:

-

Steam heating, Electric heating, Direct fire

-

Thickness:

-

1.5mm-3mm

-

Equipment Usage:

-

Beer Brewing, Beer Fermentation, Beer Production ect

-

Control system:

-

manual or semi-automatic or PLC

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

3P 380V/ 1P 220V (Other optional)

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200KG-2000KG

-

Certification:

-

CE, ISO, SGS

-

Name:

-

TONSEN ethanol plant winery used distillery equipment

-

Application:

-

Beer equipment

-

Material:

-

SUS304/SUS316/red Copper

-

Capacity:

-

50-10000L

-

Heating method:

-

Steam heating, Electric heating, Direct fire

-

Thickness:

-

1.5mm-3mm

-

Equipment Usage:

-

Beer Brewing, Beer Fermentation, Beer Production ect

-

Control system:

-

manual or semi-automatic or PLC

-

Technology Advantage:

-

PU insulation, dimple jacket, cooling system ect

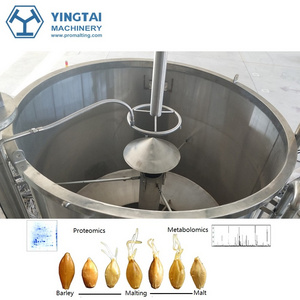

TONSEN ethanol plant winery used distillery equipment

Products Description

1) Tonsen

ethanol plant wineryused distillery equipment

s

from 50L to 10000L and average 25% Head Space.

2) All the ethanol plant wineryused distillery equipment s have a Dish top.

3) Cylinder body & 60/70° Cone Bottom.

4) Certified stainless steel(304,316) material for ethanol plant wineryused distillery equipment s , with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6) All the ethanol plant wineryused distillery equipment s use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

7) We can customize fabricate any ethanol plant wineryused distillery equipment s to meet your brewery’s space and height restrictions.

2) All the ethanol plant wineryused distillery equipment s have a Dish top.

3) Cylinder body & 60/70° Cone Bottom.

4) Certified stainless steel(304,316) material for ethanol plant wineryused distillery equipment s , with 100% TIG welded joints and seams with sanitary interior polish.

5) Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

6) All the ethanol plant wineryused distillery equipment s use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

7) We can customize fabricate any ethanol plant wineryused distillery equipment s to meet your brewery’s space and height restrictions.

|

Capacity/batch

|

100L

|

200L

|

300L

|

500L

|

1000L

|

|

Model

|

TS-100L

|

TS-200L

|

TS-300L

|

TS-500L

|

TS-1000L

|

|

Area

|

15M2

|

25M2

|

35M2

|

45M2

|

80M2

|

|

Power

|

8kw

|

12kw

|

20kw

|

35kw

|

35/15kw

|

|

Frementation cycle

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

Details Images

Manufacturing Technique

Certificates

Customer Visit

Installation Cases

50 liter hotel brewery home beer brewing pot/

ethanol plant wineryused distillery equipment

1000 liter hotel brewery home beer brewing pot/

ethanol plant wineryused distillery equipment

300 liter hotel brewery home beer brewing pot/

ethanol plant wineryused distillery equipment

Exhibition Tonsen

Packaging & Delivery

Service & Feedback

Pre-sales Service

Technical Drawing

We will offer technical drawings of each tank based on the equipment layout.

Layout design

Send us your building floor plan, or the sketch, or tell us the size(length, width, height), we will offer you an equipment footprint according to your requirement.

3D Drawing

We will 3D effective sketch to make sure you have a more intuitive experience.

After-sales Service

WARRANTY

1.Main product

ethanol plant wineryused distillery equipment

for 3 years and auxiliary parts for 1 year.

2.Lifetime repair guarantee.

3.All spare parts and wearing parts are attached with the machinery for free.

SERVICE

2.Lifetime repair guarantee.

3.All spare parts and wearing parts are attached with the machinery for free.

SERVICE

1.Free consultation service before,during,and after sales.

2.Project planning and design the layout service.

3.Free debugging instruction of equipment until everything is functional.

4.Management of equipments' long distance shipping from seller's factory to named pord or station by buyer.

5.Training of equipment maintenance and operation personally.

6.New production techniques.

2.Project planning and design the layout service.

3.Free debugging instruction of equipment until everything is functional.

4.Management of equipments' long distance shipping from seller's factory to named pord or station by buyer.

5.Training of equipment maintenance and operation personally.

6.New production techniques.

Customer Feedback

FAQ

1.Q: Can you do OEM or ODM?

A: Yes, we can do.

2.Q: How to control temperature ?

A:PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

3.Q: Is possible to supply installation in our country ?

A: Yes, we could supply engineer to supply installation guidance and training.

4.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

A: Yes, we can do.

2.Q: How to control temperature ?

A:PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

3.Q: Is possible to supply installation in our country ?

A: Yes, we could supply engineer to supply installation guidance and training.

4.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

Hot Searches