- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

jiangsu,china

-

Application:

-

Industrial,construction,etc

-

Grade:

-

alloy

-

Ni (Min):

-

58

-

Model Number:

-

inconel 625

-

Brand Name:

-

cunrui

-

Surface::

-

Bright/black

-

Type::

-

Nickel rod

-

Application::

-

Industrial,construction,etc

-

Grade::

-

Nickle, inconel 625

-

Sample::

-

Avaliable

-

Resistance (μΩ.m)::

-

1.5

-

Powder Or Not::

-

Not Powder

-

Standard::

-

ASTM/JIS/DIN/GB

-

Certificate::

-

ISO

-

Technique:::

-

Cold Rolled Hot Rolled

Quick Details

-

Resistance (μΩ.m):

-

1.5

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

750

-

Elongation (≥ %):

-

30

-

Place of Origin:

-

jiangsu,china

-

Application:

-

Industrial,construction,etc

-

Grade:

-

alloy

-

Ni (Min):

-

58

-

Model Number:

-

inconel 625

-

Brand Name:

-

cunrui

-

Surface::

-

Bright/black

-

Type::

-

Nickel rod

-

Application::

-

Industrial,construction,etc

-

Grade::

-

Nickle, inconel 625

-

Sample::

-

Avaliable

-

Resistance (μΩ.m)::

-

1.5

-

Powder Or Not::

-

Not Powder

-

Standard::

-

ASTM/JIS/DIN/GB

-

Certificate::

-

ISO

-

Technique:::

-

Cold Rolled Hot Rolled

0.025 mm corrosion resistance nickel nichrome wire with cheap price

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Bar,Pipe/tube,sheet/plate,Forging,Ring,Coil,Flange,Ribbon,Square pipe/bar, |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; etc | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750;ETC | |

| Incoloy: Incoloy 800/800H/800HT/825/925/926; etc | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044, etc | |

| Monel: Monel 400/K500/R405, etc | |

| Nitronic: Nitronic 40/50/60; etc | |

| Nimonic: Nimonic 75/80A/90/A263 ; etc | |

| Specification |

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

|

Product

Characteristics |

1.According to the preparation process can be divided into deformation superalloys,

casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Inspection | ISO,SGS,BV and so on. |

| Packaging | All our products are packed, stored, transported according to the international regulation.Or as customer's requirement provide special packing. |

Inconel 625

Features:Inconel 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Inconel 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Applications:Chemical process industry and sea water application. Inconel 625 is used in short term applications at temperatures up to 816℃. For long term service, it is best restricted to a maximum of 593℃, because long term exposure above 593℃ will result in significant embrittlemen

Chemical Composition

| Cr | Ni | Mo | Co | Nb | Al | Ti | C |

|---|---|---|---|---|---|---|---|

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | 0.40 max | 0.40 max | 0.10 max |

| Fe | Mn | Si | P | S |

|---|---|---|---|---|

| 5.0 max | 0.50 max | 0.50 max | 0.015 max | 0.015 max |

Density and Melting point

| Density | Melting point |

|---|---|

| 8.44g/cm³ | 1290-1350°C |

Mechanical Properties

| Finish Condition | Tensile strength Rm N/mm² | Yield strength R P 0. 2N/mm² | Elongation (%) Min | HB |

|---|---|---|---|---|

| Solution treatment | 760 | 345 | 30 | ≤220 |

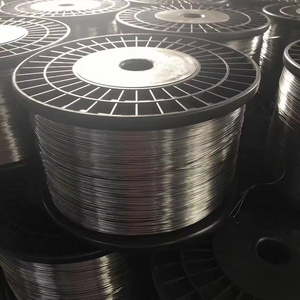

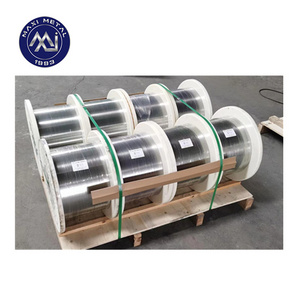

pictures of products

Factory & packaging

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Any further questions, please feel free to contact us!