- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Customized

-

Mould material:

-

Aluminum A356

-

Mould base:

-

Mr.Mould Customed

-

Design software:

-

NX_UG

-

Cavity:

-

Multi

-

Mould life:

-

5000 Times

-

Surface treatment:

-

Polishing, Texture

-

Plastic material:

-

LLDPE, MDPE and HDPE

-

Size:

-

Customer Size Accepted

-

Type:

-

die casted with CNC process

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Jiechuang

-

Model Number:

-

Customized

-

Mould material:

-

Aluminum A356

-

Mould base:

-

Mr.Mould Customed

-

Design software:

-

NX_UG

-

Cavity:

-

Multi

-

Mould life:

-

5000 Times

-

Surface treatment:

-

Polishing, Texture

-

Plastic material:

-

LLDPE, MDPE and HDPE

-

Size:

-

Customer Size Accepted

-

Type:

-

die casted with CNC process

High Quality Rotational Molding Plastic Fish Storage Container mould molds aluminum rotomolding plastic flower pot,led flower pot by roto molding,rotational moulding custom aluminum rotational molding car fender mould /auto fender mould cast aluminum rotational moulding dust bin moulds high quality plastic sweeper shell made by rotational molding rotomolding cooler box manufactured by rotomolding rotational mold plastic umbrella holder manufactured by rotomolding rotational mold aluminum rotomolded mould by cnc process polyethylene rotomolded rotational mold by die cast with CNC process

Waterproof Military Plastic Equipment Storage Tool Box Case

2016 Heat insulation box aluminum rotational mold rotomolding ice box by rotational molding aluminium rotational mold and plastic rotational molding Custom kids sliding rotational molding Rotomolding molding parts for outdoor playground rotomold cnc process rotational molding mold molds mould aluminum rotational molding mold by rotomold aluminium rotational mold and plastic rotational molding custom aluminum rotational molding kayak mold case and container cleaing and saburaruib products craft and garden products kayak and surfboat outdoor public facility toys containement pallet traffic fender by rotaional mold/plastic fender mold automobile parts environmental facility road barrier and taffice facility pet products plastic part for scrubber shell by rotational molding About Rotational Moulding aluminum mould for plastic PE insulation box box by

Wooden case for molds, customized carton for plastic products

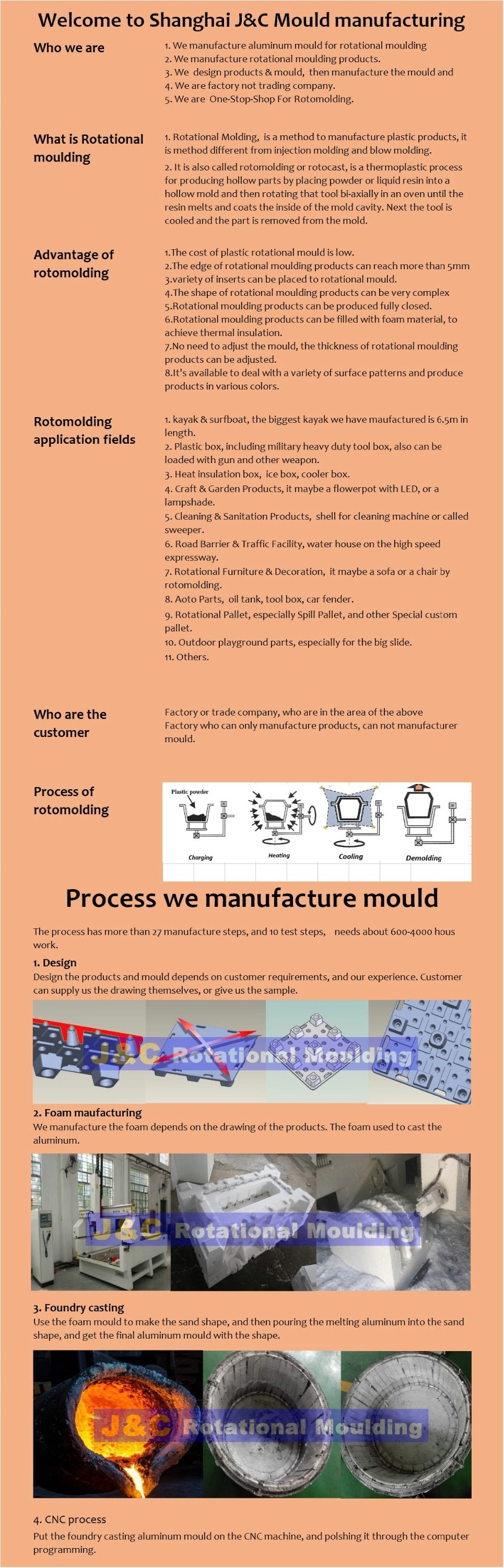

1. Design & Engineering Services

Beginning a new project starts with a solid design concept. Our in-house Design & Engineering Department will help advise and manage your project all the way to a produced rototmolded part.

Whether your project is a rough idea or a 3D model, we believe in developing a partnership early on with the customer and strive to reduce lead times and so both parties benefit from rotational molding.

2. Rotational Molding Design Guides

· Minimum wall separation 5x wall thickness (a)

· Minimum wall separation 3x wall thickness (b)

· Uniform wall thickness ± 20% (c)

· ±10% is considered precise tolerance (c)

· Wall thickness .090" to 1.00" (c)

· Different wall thickness can be produced based on functional requirements

· Large flat areas need a crown or ribs (d)

· Corners need minimum radius of 3/16"(e)

· Structural strength

· Reinforcing ribs - average proportions

· Height 4x wall thickness (f)

· Width 5x wall thickness (g)

· Kiss-off ribbing (h)

· Part Finishing and Secondary Operations

Note: Design Guide information is based on Linear Low Density Polyethylene (LLDPE) other materials tolerance can vary.

3. Cast Tooling Pattern

When your design is finalized the pattern production begins. Most commonly patterns are CNC machined from the 3D model, but other options are available.

After the pattern is reviewed and signed-off on, the followers for determining the parting lines are constructed. Next, the pattern goes through the sand ramming process creating the cope and drag. Then our Tooling Department is ready to pour the tool.

4.Rotational Molding Plastic Parts

Rotational Molding, also called rotomolding or rotocast, is a thermoplastic process for producing hollow parts by placing powder or liquid resin into a hollow mold and then rotating that tool bi-axially in an oven until the resin melts and coats the inside of the mold cavity. Next the tool is cooled and the part is removed from the mold.

Four steps in manufacturing a rotational molded part

1. Fill the mold with a polymer material

2. Heat tool in oven to melt material

3. Cool tool to solidifies the part

4. Remove part from the tools