- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MC

-

Voltage:

-

380V/50Hz/3P(or customized)

-

Dimension(L*W*H):

-

1800*1000*1320mm

-

Weight (KG):

-

1900 KG

-

Name:

-

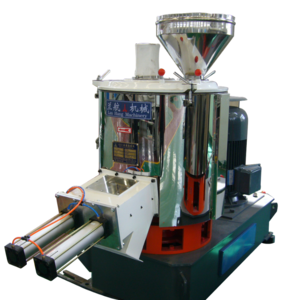

SHR-200A PVC High Speed Hot Mixer

-

Usage:

-

mixing plastic powder,chemical powder,rubber powder,kaolin soil etc

-

Total volume:

-

200Liter

-

Mixing motor power:

-

30/42KW(double speed motor)

-

Main mixing speed:

-

475/950RPM

-

Inner Barrel Material:

-

stainless steel

-

Mixing knife material:

-

stainless steel

-

Heating method:

-

Self friction/Electric Heating

-

Discharge method:

-

Pneumatic

-

Keywords:

-

SHR-200A PVC High Speed Hot Mixer

Quick Details

-

Capacity (kg):

-

100

-

Output (kg/h):

-

500 - 600 kg/h

-

Application:

-

high speed mixing,coloring and drying

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

MC

-

Voltage:

-

380V/50Hz/3P(or customized)

-

Dimension(L*W*H):

-

1800*1000*1320mm

-

Weight (KG):

-

1900 KG

-

Name:

-

SHR-200A PVC High Speed Hot Mixer

-

Usage:

-

mixing plastic powder,chemical powder,rubber powder,kaolin soil etc

-

Total volume:

-

200Liter

-

Mixing motor power:

-

30/42KW(double speed motor)

-

Main mixing speed:

-

475/950RPM

-

Inner Barrel Material:

-

stainless steel

-

Mixing knife material:

-

stainless steel

-

Heating method:

-

Self friction/Electric Heating

-

Discharge method:

-

Pneumatic

-

Keywords:

-

SHR-200A PVC High Speed Hot Mixer

Product Description

Product Application

SHR-200A PVC High Speed Hot Mixer

is used in mixing,blending,drying,coloring material in plastics,rubber and chemical industries.

SHR serious high speed mixer adopts advanced design,it is convenient and safe for operation.It offers small size,light

weights,high efficiency,low energy consumption,and low noise.

SHR serious high speed mixer adopts advanced design,it is convenient and safe for operation.It offers small size,light

weights,high efficiency,low energy consumption,and low noise.

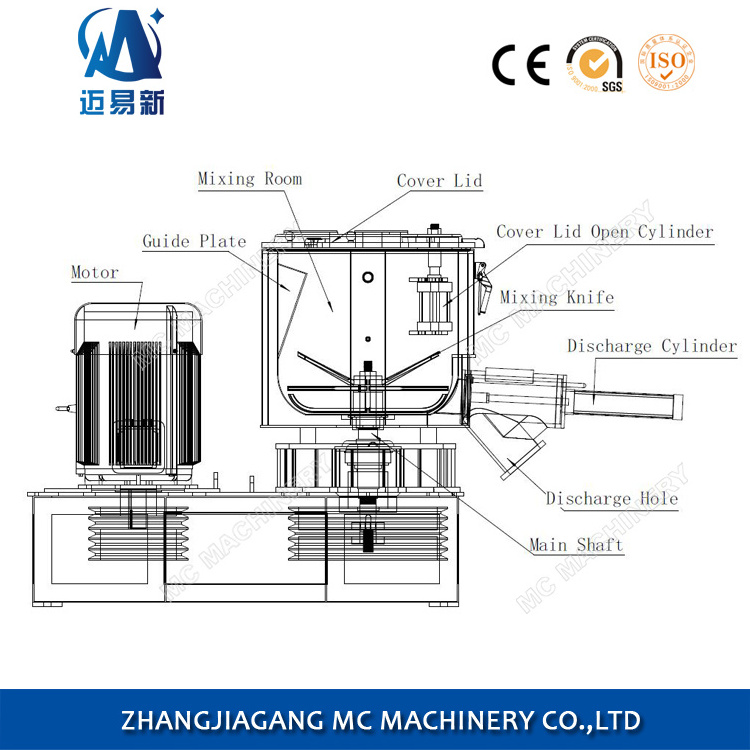

Features:

1. Mixing Barrel is all made by stainless steel,the inner surface is smooth and hard, with wear resistance, corrosion resistance,not easy sticky material.

2. Heating method can choose self friction,electric and oil heating method,according to your real temperature mixing demand.

3. Cover lid is made by aluminum casting,adapt double seal, no leakage of powder.

4.Mixing knife are made by stainless steel,and it is tested by dynamic and static.

2. Heating method can choose self friction,electric and oil heating method,according to your real temperature mixing demand.

3. Cover lid is made by aluminum casting,adapt double seal, no leakage of powder.

4.Mixing knife are made by stainless steel,and it is tested by dynamic and static.

Machine Parameter

|

Model

|

SHR-10A

|

SHR-25A

|

SHR-50A

|

SHR-100A

|

SHR-200A

|

SHR-300A

|

|||||

|

Total Volume(Liter)

|

10

|

25

|

50

|

100

|

200

|

300

|

|||||

|

Effective volume(Liter)

|

7

|

20

|

35

|

75

|

150

|

225

|

|||||

|

Motor power(KW)

|

3

|

5.5

|

7/11

|

14/22

|

30/42

|

40/55

|

|||||

|

Main shaft speed(r/min)

|

720/1440

|

720/1440

|

720/1440

|

650/1300

|

475/950

|

475/950

|

|||||

|

Heating method

|

Electric heating or Self friction

|

|

|

|

|

|

|||||

|

Discharge method

|

Manual or Pneumatic

|

|

|

|

|

|

|||||

|

Model

|

SHR-500A

|

SHR-800A

|

SHR-1000A

|

||

|

Total Volume(Liter)

|

500

|

800

|

1000

|

||

|

Effective volume(Liter)

|

375

|

600

|

750

|

||

|

Motor power(KW)

|

55/75

|

60/90

|

83/110

|

||

|

Main shaft speed(r/min)

|

430/860

|

370/740

|

350/700

|

||

|

Heating method

|

Electric heating or Self friction

|

|

|

||

|

Discharge method

|

Manual or Pneumatic

|

|

|

||

If you have interests in our machine,please do not hesitate to send us an inquiry!

Detailed Images

Our Service

Pre-Sales Service

* We given client the details technician offer.

* Professional advice for Inquiry and technical support.

* supply the details layout, installation instruction, technician support for the clients

* View our Factory,sales manager accompany.

* 24 hours English support.

* Professional advice for Inquiry and technical support.

* supply the details layout, installation instruction, technician support for the clients

* View our Factory,sales manager accompany.

* 24 hours English support.

After-Sales Service

* We arrange engineer to install the machinery and training the workers for client abroad if clients required.

* We have 24 hours team to solve problems after sales.

* We have free spare parts with the right machine during warranty time.

* We supply whole machine lifetime spare parts for every customer with low cost after warranty time.

* We always up date the new technology to every customer.

* We have 24 hours team to solve problems after sales.

* We have free spare parts with the right machine during warranty time.

* We supply whole machine lifetime spare parts for every customer with low cost after warranty time.

* We always up date the new technology to every customer.

If you have interests in our machine,please do not hesitate to send us an inquiry!

Packing & Delivery

Related Products

Our Company

FAQ

1.How about the quality of your product?

Marksim:

1)Our products manufactured strictly according to national and international standard

2)We have CE ,ISO,BV,SGS certification

3)We take testing on every product before delivery.

4)Our quality supervision department oversees the whole process during manufacturing and machine testing before machine made

shippment.

2.What is the MOQ?

2)We have CE ,ISO,BV,SGS certification

3)We take testing on every product before delivery.

4)Our quality supervision department oversees the whole process during manufacturing and machine testing before machine made

shippment.

2.What is the MOQ?

Marksim:

1 set.

3.If you can make machine custom-made?

Marksim: Yes,we can make products special design according to customer's requirements.

4.What is the machine voltage?

Marksim: Normally 380V,50hz,3 phase.But we can change it according to customer's requirement, like 220V,240V,415V,440V,600V and so on.

5.What is this machine guarantee time?

Marksim: 1 year

6.When the machine can be deliveried?

3.If you can make machine custom-made?

Marksim: Yes,we can make products special design according to customer's requirements.

4.What is the machine voltage?

Marksim: Normally 380V,50hz,3 phase.But we can change it according to customer's requirement, like 220V,240V,415V,440V,600V and so on.

5.What is this machine guarantee time?

Marksim: 1 year

6.When the machine can be deliveried?

Marksim:

Normally 30 working days.

7.We want to visiting your factory first before order,if it is avaliable?

7.We want to visiting your factory first before order,if it is avaliable?

Marksim:

Yes,welcome to visit our factory any time,our factory normally have ready machines in stock,you can see real machine by your eyes and it will be the best for you to know our machine and our company.

8.If we finally buy your machine,you can send engineers to our country and help installation and training our workers?

Marksim: Yes,of course,if you needed,we will send engineer to your country to your factory to help installation and training your workers,but you have to bear our engineer's flight charge around,take responsibility of engineer's food and hotel during his visiting and pay salary USD100 per day for one person.

9.I’m a foreign customer,if the machine some part is broken one day,how can we get help from you?

8.If we finally buy your machine,you can send engineers to our country and help installation and training our workers?

Marksim: Yes,of course,if you needed,we will send engineer to your country to your factory to help installation and training your workers,but you have to bear our engineer's flight charge around,take responsibility of engineer's food and hotel during his visiting and pay salary USD100 per day for one person.

9.I’m a foreign customer,if the machine some part is broken one day,how can we get help from you?

Marksim:

If the machine part is broken,during warranty we will sending spare parts to you without any charge and help you make it change to new by phone or whatsapp or video.If out of warranty,we will also provide you spare part but with raw material cost,and we also will help you change to new instead of broken part.We provide spare parts and technical service whole machine lifetime.

If you have interests in our machine,please do not hesitate to send us an inquiry!

Hot Searches