- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BLT

-

Voltage:

-

380V/50Hz/3phase(Customised)

-

Dimension(L*W*H):

-

1300*850*1600mm

-

Power (kW):

-

5

-

Weight (T):

-

0.5

-

Color::

-

Customised

-

Motor:

-

1

-

Crushing port size:

-

200/300/400/500

-

Feeding port size:

-

400/600*400/700*300/400mm

-

Suitable material:

-

metal,plastic,wood,tyre,waste rubbish,etc

-

Size:

-

Standards and customization

-

Power(W):

-

4KW

-

Capacity:

-

300-1000kg/H

-

Weight:

-

300kg

Quick Details

-

Max.Production Capacity (kg/h):

-

4500

-

Place of Origin:

-

Jiangsu, China

-

Production Capacity (kg/h):

-

500 - 1000 kg/h

-

Brand Name:

-

BLT

-

Voltage:

-

380V/50Hz/3phase(Customised)

-

Dimension(L*W*H):

-

1300*850*1600mm

-

Power (kW):

-

5

-

Weight (T):

-

0.5

-

Color::

-

Customised

-

Motor:

-

1

-

Crushing port size:

-

200/300/400/500

-

Feeding port size:

-

400/600*400/700*300/400mm

-

Suitable material:

-

metal,plastic,wood,tyre,waste rubbish,etc

-

Size:

-

Standards and customization

-

Power(W):

-

4KW

-

Capacity:

-

300-1000kg/H

-

Weight:

-

300kg

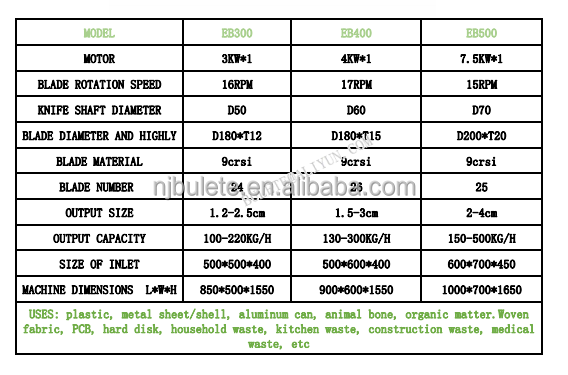

Description:

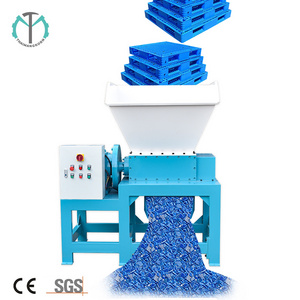

Shredder is mainly used in all kinds of hollow or solid plastic material. The shredder machine is

suitable to PE, PP, PET, ABS, PVC and engineering plastics..

Application range of shredder

Workshop production

Customer visit and negotiation

Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power

slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating

90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating

180 degree

6)Quiet operation at low speed

7)Screen mesh is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume,

material to be processed, etc.