- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

25000 ml

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Year:

-

new

-

Voltage:

-

220v/380V

-

Dimension(L*W*H):

-

230*74*200cm

-

Hollow part volume:

-

2.7

-

Clamping Force (kN):

-

100

-

Power (kW):

-

16kw

-

Weight (KG):

-

650 KG

-

Product name:

-

Blow Molding Machine

-

Suitable bottle:

-

PET Bottle Size 100ml-20L

-

Key words:

-

Bottle Blow Making Machine

-

Type:

-

Stretch Pet Blow Moulding

-

Bottle material:

-

Pet Plastic

-

Machine type:

-

High Speed Blow Molding Machine

-

Name:

-

Plastic Bottle Machine

-

Capacity:

-

500-10000 BPH

-

Function:

-

Pet Bottle Blow Making Machine

-

Keywords:

-

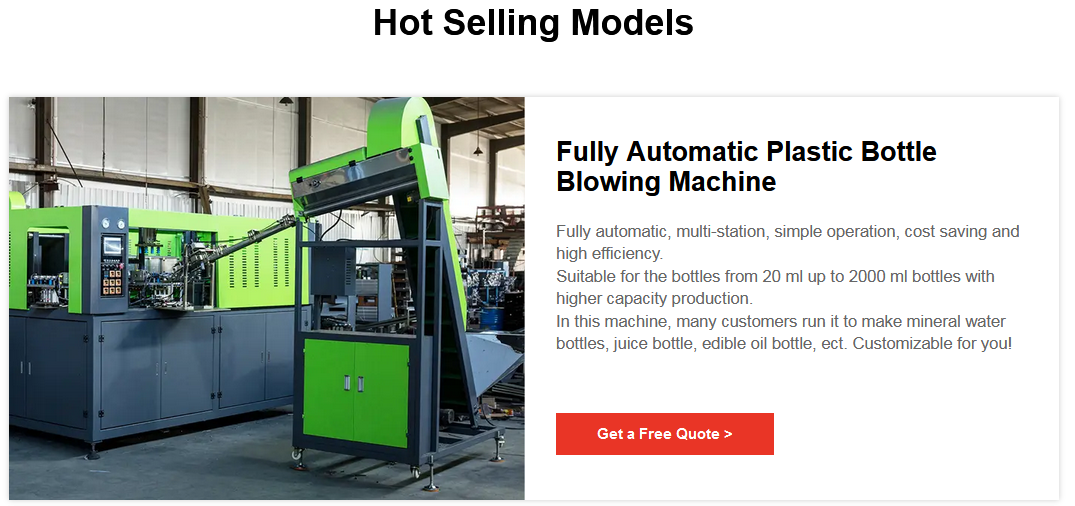

Fully Automatic Bottle Blowing Machine

Quick Details

-

Neck Diameter(mm):

-

125 mm

-

Max.Bottle Diameter(mm):

-

300 mm

-

Max.Bottle Height(mm):

-

500 mm

-

Bottle Volume(ml):

-

25000 ml

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong

-

Year:

-

new

-

Voltage:

-

220v/380V

-

Dimension(L*W*H):

-

230*74*200cm

-

Hollow part volume:

-

2.7

-

Clamping Force (kN):

-

100

-

Power (kW):

-

16kw

-

Weight (KG):

-

650 KG

-

Product name:

-

Blow Molding Machine

-

Suitable bottle:

-

PET Bottle Size 100ml-20L

-

Key words:

-

Bottle Blow Making Machine

-

Type:

-

Stretch Pet Blow Moulding

-

Bottle material:

-

Pet Plastic

-

Machine type:

-

High Speed Blow Molding Machine

-

Name:

-

Plastic Bottle Machine

-

Capacity:

-

500-10000 BPH

-

Function:

-

Pet Bottle Blow Making Machine

-

Keywords:

-

Fully Automatic Bottle Blowing Machine

Product Description

PET cottle blow molding machine

Blow Molding Machine has high configuration, high cost performance and high output, this series of PET bottle blowing machines are loved by major mineral water manufacturers, beverage factories, hand and cosmetic bottle factories at home and abroad.

This bottle blowing machine is widely used in mineral water bottles, soda bottles, fruit juice bottles, aerated beverage bottles, wine bottles, soy sauce, vinegar and other seasoning bottles, cosmetics bottles, hand washing bottles, etc.

Specification

|

Main parameters: 4 Cavity blow molding machine

|

|

|

||

|

heading

|

Unit

|

Data

|

||

|

cavity

|

Pcs

|

4

|

||

|

theoretical outout

|

Pcs/hr

|

1800-2000

|

||

|

max.container volume

|

L

|

2

|

||

|

max.thead size

|

MM

|

120

|

||

|

max.container diameter

|

MM

|

200

|

||

|

max.container height

|

Mm

|

250

|

||

|

mold thickness

|

Mm

|

170-280

|

||

|

mould opening stroke

|

mm

|

230

|

||

|

Total power

|

KW

|

15

|

||

|

heater power

|

KW

|

18

|

||

|

weight of machine

|

KG

|

1100

|

||

|

weight of oven

|

KG

|

550

|

||

|

size of machine

|

mm

|

1900*790*1800

|

||

|

size of oven

|

mm

|

2050*660*1600

|

||

|

|

|

|

||

Packing & Delivery

1.B

ottle blowing machine

Packaging:

1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Bottle blowing machine Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Bottle blowing machine Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

Hot Searches