- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

300*150*100 mm

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

220/380/440v

-

Dimension(L*W*H):

-

140*85*145(cm)

-

Weight (KG):

-

450 kg

-

Product Name:

-

QTY2-20 Interlocking Brick Making Machinery

-

Raw material:

-

Clay Earth Soil Mud

-

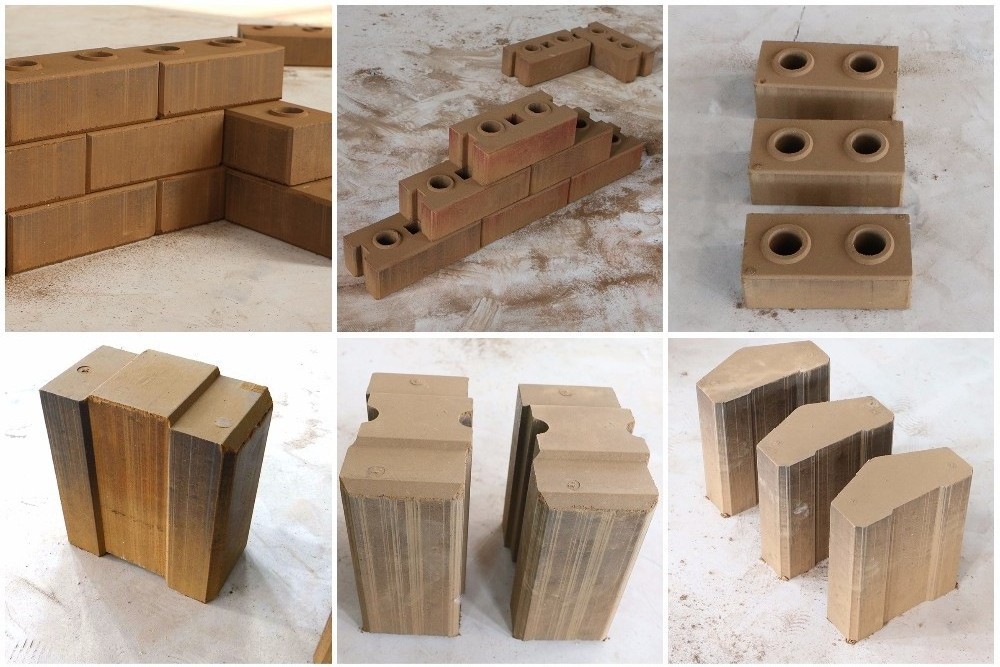

Brick type:

-

Interlock Brick Clay Brick Hole Brick

-

Color:

-

Customized as required

-

Molding cycle:

-

25s

-

The molding pressure:

-

7 (T)

-

The transmission way:

-

hydraulic

Quick Details

-

Type:

-

Hollow Block Making Machine, Interlock Block Making Machine, Other

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

2500 pcs/8hours

-

Brick size:

-

300*150*100 mm

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

QINTAO

-

Voltage:

-

220/380/440v

-

Dimension(L*W*H):

-

140*85*145(cm)

-

Weight (KG):

-

450 kg

-

Product Name:

-

QTY2-20 Interlocking Brick Making Machinery

-

Raw material:

-

Clay Earth Soil Mud

-

Brick type:

-

Interlock Brick Clay Brick Hole Brick

-

Color:

-

Customized as required

-

Molding cycle:

-

25s

-

The molding pressure:

-

7 (T)

-

The transmission way:

-

hydraulic

Product Description

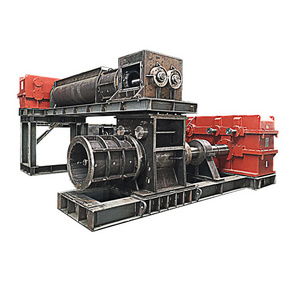

QTY2-20

Clay interlocking brick machine

smooth operation and stable performance, which is newly developed by Shaanxi Qintao Machinery Technology Co., LTD

according to the demand of domestic and foreign markets. Its operation is simple, quick, accurate and in place, smooth

out, will make you at a glance.

* Although the machine is small, it can produce several types of brick by changing the mold. Its quick disassembly, light

* Although the machine is small, it can produce several types of brick by changing the mold. Its quick disassembly, light

and flexible, easy to master.

* Its good use effect has long been praised by the majority of users. It is suitable for Africa and South America where

electricity is scarce.

* Its good use effect has long been praised by the majority of users. It is suitable for Africa and South America where

electricity is scarce.

* Connect the external power supply, close the combined switch, and the current indicator is on.

* Observe and confirm that there is no obstacle around the motor: press the motor start button. The current indicator is on

and the motor starts to run. Hydraulic fluid is entering the system.

* Open the return channel of the compacting cylinder to make the cylinder return to the top dead center, and then open the

discharging cylinder to start discharging. When the discharging cylinder comes to the end point, the cylinder will return

* Open the return channel of the compacting cylinder to make the cylinder return to the top dead center, and then open the

discharging cylinder to start discharging. When the discharging cylinder comes to the end point, the cylinder will return

to the starting point and stop the oil supply. At this time the discharging function is complete, the hopper is full. The

compaction cylinder can now be started.

* Start the compaction cylinder to pressure the material: to be about to complete the compaction condition before the

* Start the compaction cylinder to pressure the material: to be about to complete the compaction condition before the

height of 5-10mm, the machine pressure gauge starts to move, only need a second time, the pressure rises to 16mpa

scale, at this time the cylinder stroke is completed, the brick compaction height is reached, that is, the compaction

process is completed.

* the hydraulic control handle is pushed up, the cylinder will rise up, and start the demoulding mechanism to top out the

brick from the mold, that is, to complete the compaction process.

* manually press the brick code to the transport vehicle, the end of a brick pressing procedure. And can be linked to the

* the hydraulic control handle is pushed up, the cylinder will rise up, and start the demoulding mechanism to top out the

brick from the mold, that is, to complete the compaction process.

* manually press the brick code to the transport vehicle, the end of a brick pressing procedure. And can be linked to the

next discharging process. So to achieve the purpose of continuous production.

* Using clay as raw material and adding 8% of cement to save cost, its brick type has strong chain property, and the

covered house has good earthquake resistance.

* Hydroforming, high density and high strength.

* Patented products with reliable quality.

* The production process is simple and can be produced everywhere.

* Less investment, quick results, can be fully recovered after half a year of production, very suitable for countries such as

Africa.

* Can be produced all year round.

* The appearance is beautiful, the construction is convenient, the low-rise building is solid, the high-rise building is made

* Hydroforming, high density and high strength.

* Patented products with reliable quality.

* The production process is simple and can be produced everywhere.

* Less investment, quick results, can be fully recovered after half a year of production, very suitable for countries such as

Africa.

* Can be produced all year round.

* The appearance is beautiful, the construction is convenient, the low-rise building is solid, the high-rise building is made

of filler and the cost is low.

* Technical indicators are better than blue-red bricks.

* Technical indicators are better than blue-red bricks.

Specification

|

Model

|

QTY2-15

|

|

Certificate

|

CE, ISO

|

|

Molds

|

Double Molds

|

|

Capacity

|

2300-2900 bricks per day

|

|

Brick pressure

|

16-25 Mpa

|

|

Power (choice)

|

4KW

|

|

|

4 KW

|

|

Total weight

|

350 KGS

|

|

Overall size

|

140*85*145 (cm)

|

Hot Searches