- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shuguang

-

Dimension(L*W*H):

-

13.9m*4m*6.2m/18m*4.6m*8.6m

-

Weight:

-

2000 KG

-

Product name:

-

Gold Ore Grinding Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE & ISO

-

Name:

-

Micro powder grinding mill Super Fine Powder making machine

-

keywords:

-

Micro powder grinding mill

-

Color:

-

Customer Requirement

-

Installation:

-

Engineer's Guide

-

Output size:

-

0.074-0.4mm

-

Factory Visit:

-

Welcomed Warmly

-

Application:

-

Stone Powder Grinding

Quick Details

-

Marketing Type:

-

Hot Product

-

Capacity(t/h):

-

600-4000kg/h or 900-6000kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuguang

-

Dimension(L*W*H):

-

13.9m*4m*6.2m/18m*4.6m*8.6m

-

Weight:

-

2000 KG

-

Product name:

-

Gold Ore Grinding Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE & ISO

-

Name:

-

Micro powder grinding mill Super Fine Powder making machine

-

keywords:

-

Micro powder grinding mill

-

Color:

-

Customer Requirement

-

Installation:

-

Engineer's Guide

-

Output size:

-

0.074-0.4mm

-

Factory Visit:

-

Welcomed Warmly

-

Application:

-

Stone Powder Grinding

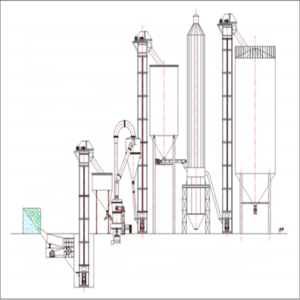

Professional manufacture Micro powder grinding mill Super Fine Powder making machine

Brief introduction of micro powder grinding mill

Micro powder grinding mill is widely used in non-metallic materials with Moh's hardness below 9 ,humidity less than 6%.Such as : calcite, calcium carbonate, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, sepiolite, punch and stick stone, rectories, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate rock, potassium ore, pumice, etc

Working principle of micro powder grinding mill

The main motor drives main axle and every layer rotating by reducer. Dail drives numbers of rollers rolling and rotating in the ring by pintles.

Big materials are crushed into smaller particles by hammer crusher. Then they are sent to store house by elevator. The electro-magnetic vibrating feeder send the materials evenly to the middle of the upper dial. Under the function of the eccentricity, the materials scatter to the side of the circle and fall into the ring to be pressed, crushed and milled into pieces by rollers. After the first crush, materials fall into the second and the third layer. The pumping of the high-pressure centrifugal blower put the outside air into the machine. The coarse powder will be brought into the classifier.

The rotating turbine in the collector makes the coarse particles fall back for regrinding. The fine particles will come into the cyclone collector with the airflow and discharged by the discharging valve on the bottom of the collector. They are the final products. The airflow with little dust will be discharged through blower and muffler after being purified by the cyclone collector.

Features

HGM tricyclic ultrafine pulverizer cavity without rolling bearing,without screws,the safe running of the equipment;the grinding of material classification,fineness high,one-time can reach D97 is or less than 5 micron.

Technical data of micro powder grinding mill

|

Model |

HGM8021 |

HGM9024 |

HGM10027 |

HGM10036 |

|

Average diameter ( mm ) |

800 |

900 |

1000 |

1000 |

|

Grinding rill and roller path number (pcs) |

3 |

3 |

3 |

4 |

|

Ring roll number (pcs) |

21 |

24 |

27 |

36 |

|

Speed of mainshaft ( r.p.min ) |

230 |

200 |

180 |

180 |

|

Feeding size / ( mm ) |

≤20 |

≤20 |

≤20 |

≤20 |

|

final size( μm ) |

5-47 |

5-47 |

5-47 |

5-47 |

|

Production capacity( t/h ) |

0.4-4.5 |

0.4-5.5 |

0.6-6.5 |

0.7-7.5 |

|

Contour dimension(m) ( LXWXH ) |

13.9x4x6.2 |

14.7x4.8x7.2 |

18x4.6x8.6 |

18x4.6x8.6 |

|

Motor power (k w ) |

145 |

192 |

263 |

263 |

| Main application and characteristics | ||||||||||

|

1. Mainly suitable for middle and low hardness, non flammable and explosive of mohs hardness level 6 or less brittle material of ultrafine powder processing, such as calcite, chalk, limestone, dolomite, carbon black, kaolin, talc, mica, bentonite, magnesite, illite and pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alum stone, graphite, fluorite, phosphate rock, potassium ore, more than 100 kinds of materials, such as pumice powder granularity of finished product in 325-2500 mesh. |

||||||||||

| 2. Environmental protection free from contamination. With efficient impulse type dust collector, no dust pollution in the whole equipment operation process, configuration muffler and quieter room, reduces the noise, completely according to the national environmental standards to organize production. | ||||||||||

| 3. The product final fineness is higher 45% than common grinder mill. | ||||||||||

| Installation | ||||||||||

| We will send technicians to the site to provide guidance on installation and | ||||||||||

| debugging and the training of operators. it takes 5-10 days | ||||||||||

Packaging term: Small parts in wooden case, machine body bare in loose.

Shipping term: Stardand container, bulk cargo carrier by sea or overland transportation.

Ocean freight partners are: APL, COSCO, OOCL, CSCL, MSC, etc. Train shipping is also available.

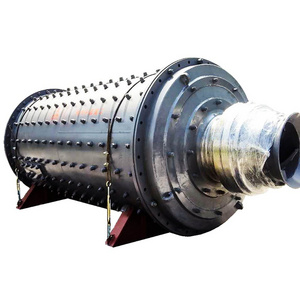

Zhengzhou Shuguang Heavy Machinery Co.ltd is founded in 1993, which specializes in production micro powder grinding mill for 21 years.We can offer different series of grindings mill, such as,high pressure mill,superfine grinding machine,three-ring medium speed milling machine,vertical calcium powder machine and so on. Besides that, we can also produce other machines,such as:ball mill,crushers,rotary dryer,coal gasifier,etc. Warmly welcome to our factory.