Features: There is convenient use, soft touch, fine scalability and impact resistance and exceptional chemical stabilty. As the result of the bad gas brrier, the dissolved aromatic cnpounds will be easy to be oxidized. It can be applied to cleansing cream, hand cream, facial mask packaging and other cosmetics.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

GFLT-100, ABL,Aluminum Barrier Laminated Tube

-

Product name:

-

Soft Collapsible Aluminum Plastic Laminated Tube

-

Diameter:

-

35mm

-

Length:

-

135mm

-

Volume:

-

100ml

-

Printing Method:

-

Offset Printing/Screen Printing

-

Color:

-

Up to 8 Colors Printing

-

Cap:

-

Screw on Cap, Flat Cap

-

Usage:

-

TOOTHPAST, Tooth Gel

Quick Details

-

Material:

-

Aluminum/Plastic

-

Cosmetic Type:

-

Cream,Lotion, Gel

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM/ODM

-

Model Number:

-

GFLT-100, ABL,Aluminum Barrier Laminated Tube

-

Product name:

-

Soft Collapsible Aluminum Plastic Laminated Tube

-

Diameter:

-

35mm

-

Length:

-

135mm

-

Volume:

-

100ml

-

Printing Method:

-

Offset Printing/Screen Printing

-

Color:

-

Up to 8 Colors Printing

-

Cap:

-

Screw on Cap, Flat Cap

-

Usage:

-

TOOTHPAST, Tooth Gel

Aluminium Barrier Laminated Tube (Silver Web)

Alminium foil thickness from 9um to 30um to meet customized requirements on barrier property and stiffness

Aluminium Barrier Laminated Tube (White Web)

Alminium foil thickness from 9um to 30um to meet customized requirements on barrier property and stiffness

Plastic Barrier Laminated Tube

EVOH with 0um to 25um to meet customized requirement on barrier property

|

Metalized Laminated Tube (AML/PML)

|

|

|

|

* Combining dry lamination with extrusion lamination process

|

|

|

|

* Excellent barrier and optional properties of VMPET

|

|

|

|

* Applications: cosmetics

|

|

|

|

( AML: Aluminium Metalized Laminates )

|

|

|

|

( PML:Plastic Metalized Laminates )

|

|

|

PRODUCT APPLICATION

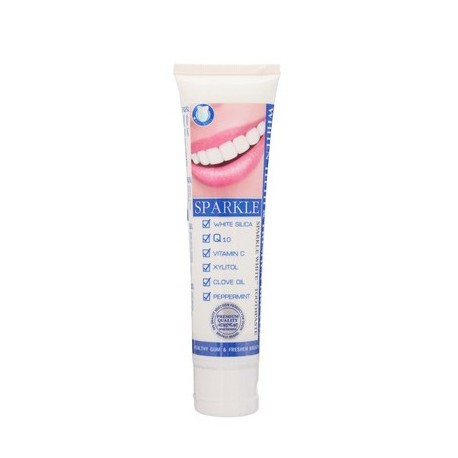

Toothpaste Tubes

Travel Size and Gift Size: Ideal for Hotel Supplies and Product Promotion

Household Toothpaste

Cosmetic Tubes

Body and Hair Care Tubes

Product Details

Orifice Options

Orifice With Membrane

Orifice Without Membrane

Orifice With Sealing Foil

Cannula Tip

Sketch Map of Tube

THE SKETCH MAP OF FIVE-LAYER TUBE

Features: Compared to two-layer tube, there are much better gas barrier properties and toughness, it can prevent Oxygen and other gases sinking into. In other words it also can stop dissolved aromatic cnpounds and other cnponents sinking out effectively. It can be applied to sun cream, hair cream, body lotion, ointment packaging and other functional products.

Printing Area on Tube

(1) Product may shrink by 2.0% following production.

(2) 1.5mm must be reserved for circumference printing.

(3) Standard size for eye mark is 2.0mm x 6.0mm, other size are available on request.

(4) No print area next to the tube shoulder is 3mm, no print area on the tube tall is 5mm, they can be adjusted according to the requirement.

Tube Diameter and Capacity

(1) Tube diameter is set, length can be adjust.

(2) Specifications are for reference only, and customer sizes are available.

(3) Above tube length are the testing result after the sealing, if customer seals the tube by himself, the tube length should increase 5-10mm.

Note:

For the compatibility between the tube body and the functional applicators please inquire our sales team

Production Process

We take every product seriously.

We take every product with a crazy persitence.

Every product goes through one and one strict procedure.

We have never beared any defective products.

Just for this crazy persitence.

We have achieved the exceptional success in the market-like a rising wind and scudding clouds.

Production Equipment

Testing Equipment

We have two independent laboratories special for injection / blow molding and tube products. Specifically, tube testing items encompass 30+ methods, like air tightness, compression resistance, head / tail sealing fixation, light fastness, ink / gloss oil

and hot stamping adhesion, labeling and sealing film fixation, water vapor permeability and appearance / safety index / hygiene

index and more. Besides, injection / blow molding products go through 10+odd tests, ranging from air tightness, fall and fatigue

resistance, compatibility, appearance, safety index and hygiene index, etc.

Hot Searches