- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

P80, P80

-

Product Name:

-

P80 Tig Cutting Torch

-

Color:

-

Picture

-

Cable Length:

-

4-10m

-

Body:

-

Plastic Body

-

Certificate:

-

ISO9001/CE

-

Delivery time:

-

About 15 Days

-

Welding Capacity:

-

Excellent

-

Cooling type:

-

Air Cooled

Quick Details

-

Type:

-

CUTTING TORCH

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Xin niu

-

Model Number:

-

P80, P80

-

Product Name:

-

P80 Tig Cutting Torch

-

Color:

-

Picture

-

Cable Length:

-

4-10m

-

Body:

-

Plastic Body

-

Certificate:

-

ISO9001/CE

-

Delivery time:

-

About 15 Days

-

Welding Capacity:

-

Excellent

-

Cooling type:

-

Air Cooled

Product Overview

Plasma cutting gun

Plasma cutting gun is a processing method that uses the heat of high-temperature plasma arc to locally melt the metal at the cut of the workpiece, and discharges the molten metal with the momentum of high-speed plasma to form a slit. It is widely used because of its fast cutting speed, high cutting accuracy, easy to set cutting conditions, easy to realize automation, unmanned operation and relatively low cost. With the combination of information technology and control technology and plasma cutting, the newly developed plasma cutting machine has made great progress in design theory, design parameters, product quality and performance in recent years.

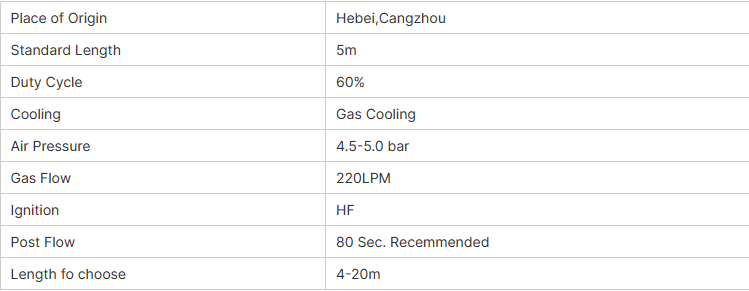

PRODUCT SPECIFICATIONS

The main reason why it has been so widely used is that it has the following advantages.

1. Reducing the burning loss of alloying elements, obtaining dense, spatter-free and high-quality welded joints;

2. Stable combustion, heat concentration, high arc column temperature, high welding productivity, narrow heat-affected zone, weldment stress, deformation and crack tendency is small;

3. welding, easy to operate and observe;

4. small electrode loss, arc length is easy to maintain, welding without flux and paint layer, easy to realize mechanization and automation;

5. Almost all metals can be welded, especially some refractory metals and easily oxidized metals, such as magnesium, titanium, molybdenum, zirconium, aluminum and its alloys;

6. Not limited by the position of the weldment, can be all-position welding

Delivery time

|

Quantity (sets)

|

1 - 2

|

3 - 100

|

101 - 300

|

> 300

|

|

Lead time (days)

|

10

|

20

|

30

|

To be negotiated

|

SALES AND SERVICE NETWORK

FEATURES AT A GLANCE

Whether it is sheet metal, chassis, cabinets, distribution boxes, mold parts and other custom products, or doors, windows, stairs, kitchen and bathroom, handicrafts, jewelry and other metal processing, or electronic components, computer shells, cell phone shells, clocks and glasses and other precision instrumentation and other industries can be used to carry out operations with a handheld laser welding machine. A large number of steel, copper, aluminum, gold, silver, chromium, nickel, titanium, tantalum and other metals and their alloys, but also for welding between different materials, can be welded graphics a little bit, straight line, round, square, and shaped materials, welding accuracy, flexibility, welding speed, easy to achieve automation.

FAQ

Q 1: Can I have a sample for testing?

A: Yes, we can provide samples. The sample fee will be charged reasonably according to the negotiation between us.

Q2: Can I customize the product icon or style on the product?

A: Yes, we have on-site factories and designers who can provide customized products according to your needs.

Q 3: Is there a product quality inspection video in the factory?

A: Of course, we have a specialized QC team to test the products before shipment.

Q 4: Can we mix the products in the whole box?

A: Yes, we can. We ship products in bulk, usually in 40-foot high cube containers, but 20-foot containers can also be used.

Q6: Can I visit your facility before placing an order?

A: Of course, you are welcome to visit our factory.

Hot Searches