- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Apartment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

Calcium Silicate Board for Thermal Insulation

-

Product Name:

-

Calcium Silicate Board for Thermal Insulation

-

Raw Materials:

-

Tobermorite,Cement,Quartz,Fiber

-

Standard Size:

-

1200*2400mm / 1220*2440mm

-

Max Width/Max Length:

-

1220mm/3050mm

-

Thickness:

-

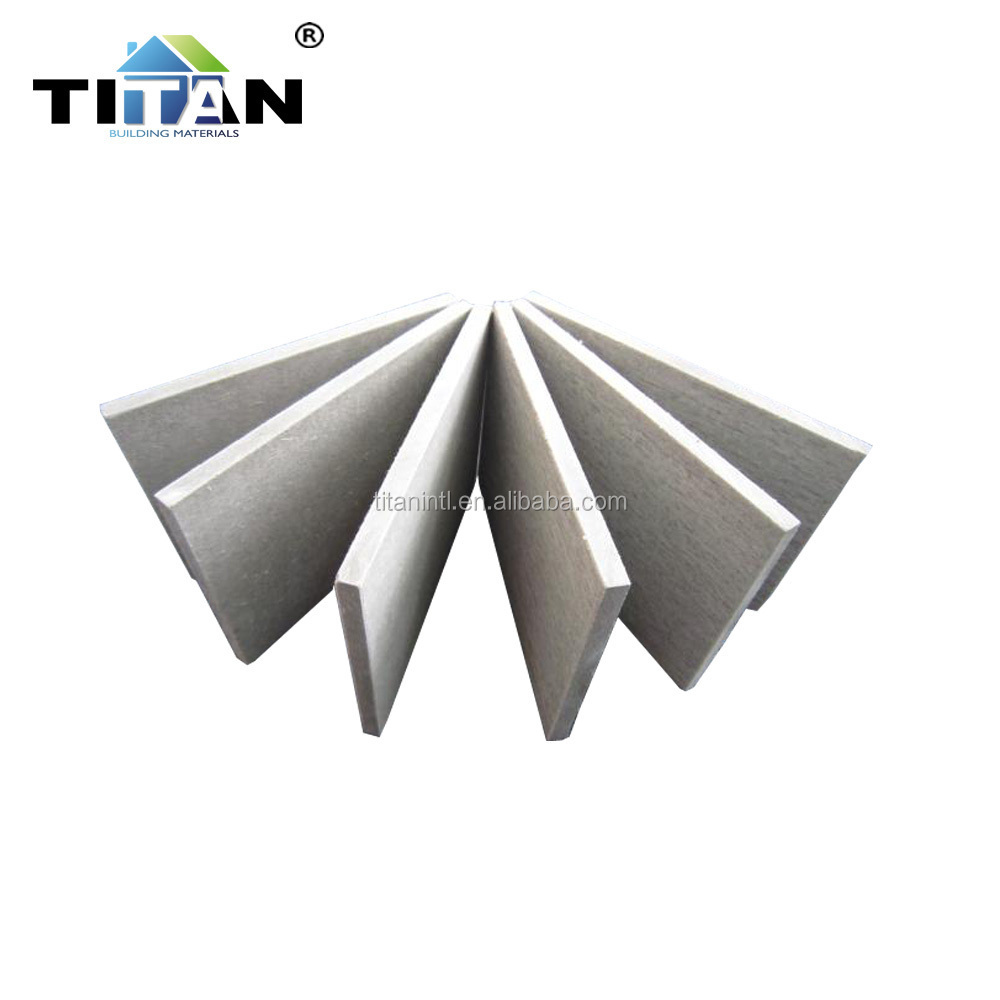

4.5~25mm

-

Edges:

-

Square / Beveled / Taper

-

Density:

-

1.0-~1.25kgs/cm3

-

Water Absorption:

-

≤40

-

Fire Resistance:

-

Incombustibility A Class(GB8624-A)

-

Thermal Conductivity:

-

Average≤0.20W/m.k

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

graphic design

-

Application:

-

Apartment

-

Design Style:

-

Contemporary

-

Place of Origin:

-

China

-

Brand Name:

-

TITAN

-

Model Number:

-

Calcium Silicate Board for Thermal Insulation

-

Product Name:

-

Calcium Silicate Board for Thermal Insulation

-

Raw Materials:

-

Tobermorite,Cement,Quartz,Fiber

-

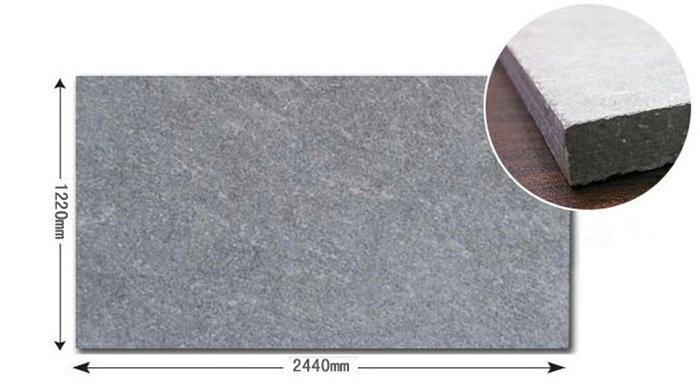

Standard Size:

-

1200*2400mm / 1220*2440mm

-

Max Width/Max Length:

-

1220mm/3050mm

-

Thickness:

-

4.5~25mm

-

Edges:

-

Square / Beveled / Taper

-

Density:

-

1.0-~1.25kgs/cm3

-

Water Absorption:

-

≤40

-

Fire Resistance:

-

Incombustibility A Class(GB8624-A)

-

Thermal Conductivity:

-

Average≤0.20W/m.k

Calcium Silicate Board for Thermal Insulation

Calcium Silicate Board

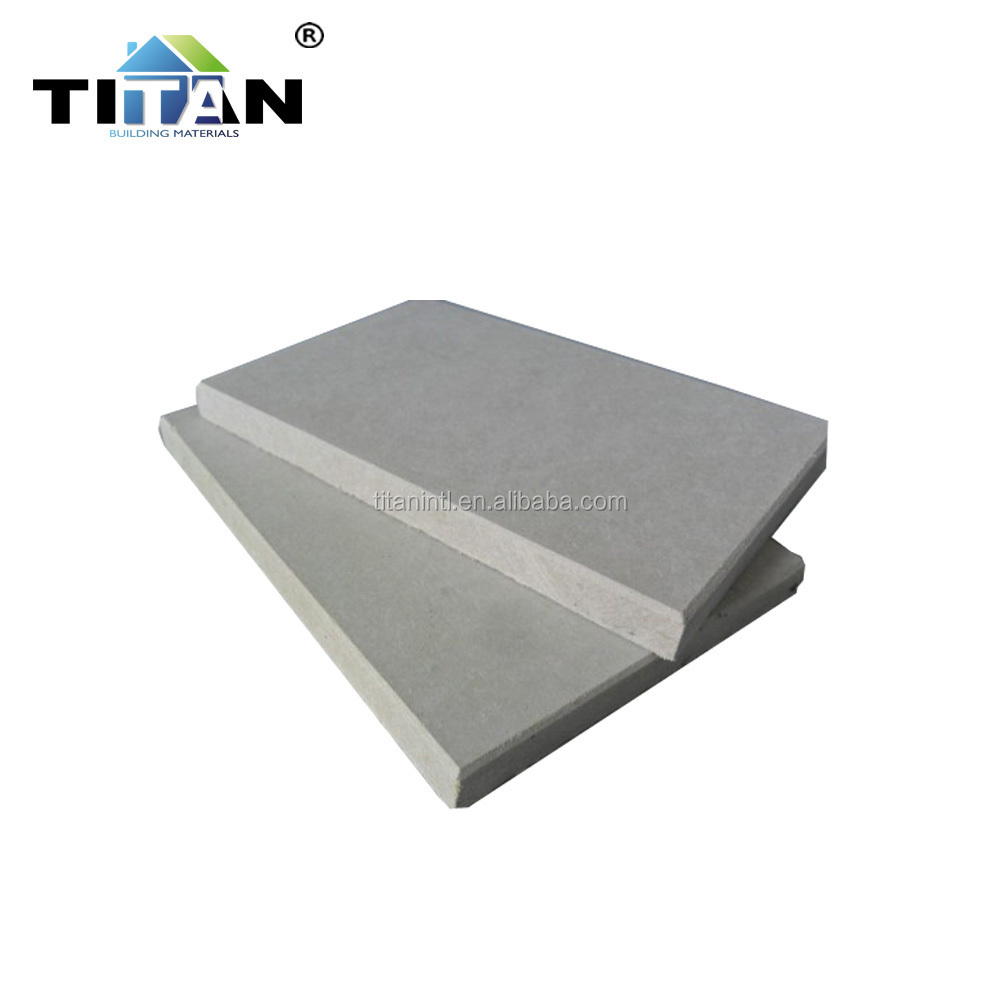

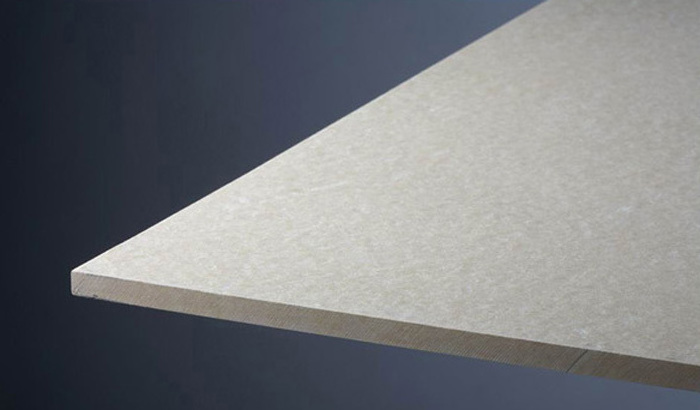

Calcium Silicate Board is a composite material made of quartz sand, cement and cellulose fibers. This product adopts imported pure paper pule from Canada, not included waste paper pulp. Fiber cement board is manufactured in a sheet form and they are used for interior and exterior suspension, partition and flooring application.The normal size is 1220×2440mm,thickness from 4.5~20mm, and density is 1.3~1.6g/cm3. There are low-density, middle-density and high-density.

Main Characteristic

1. 100% Asbestos Free

2. Fire Resistance and Moisture Resistance

3. High Strength and Good Stability

4. Inorganic Material, Anti Fungus and Antiseptic

5. Widely used in Partition and Suspension System.

|

Name: Calcium Silicate Board

|

|||

|

Normal Size |

1220mm × 244mm or 1200mm × 2400mm |

||

|

Max. Width |

1220mm |

||

|

Max. Length |

3050mm |

||

|

Thickness |

4.5mm ~ 25mm |

||

|

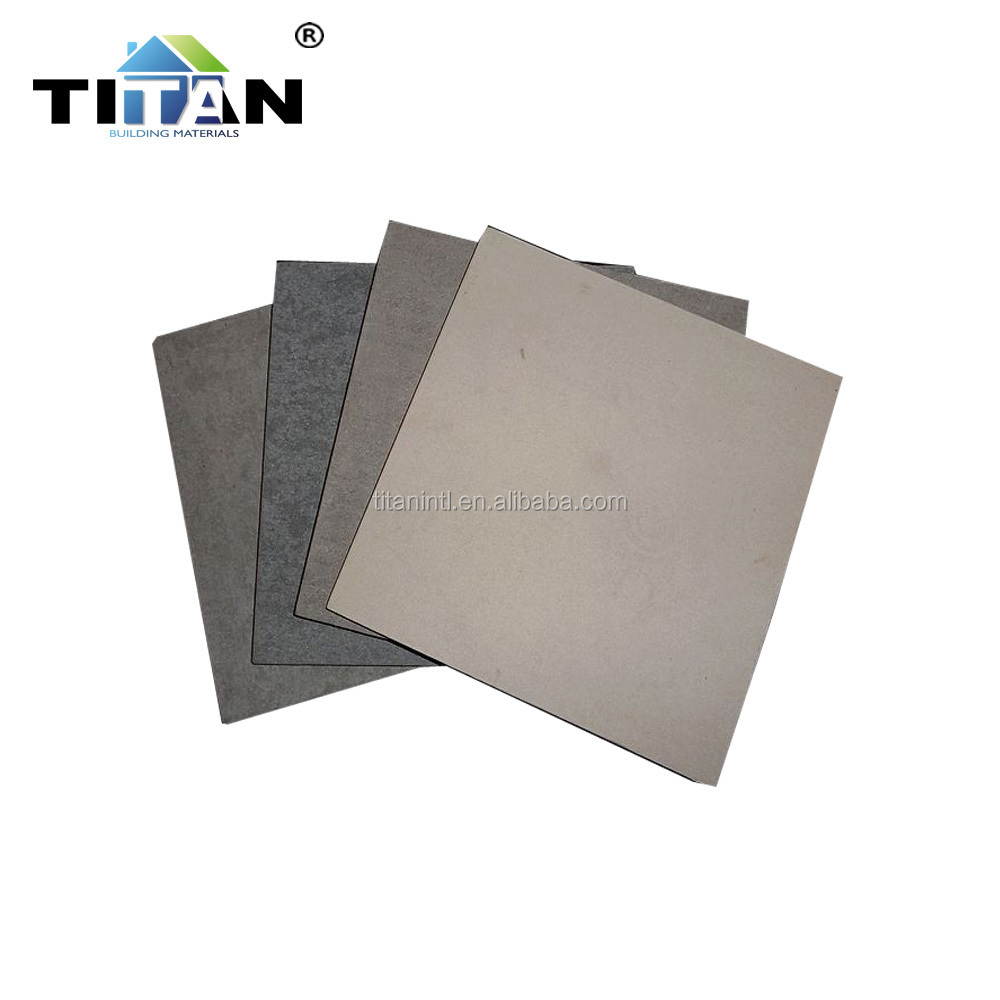

Color |

Light Grey / Dark Grey / White / Black / Yellow / Green / Red |

||

|

Edge |

|

||

|

Density |

1.2 ~ 1.5kg/cm 3 |

||

|

Water Content |

≤10 |

||

|

Water Absorption |

≤30 |

||

|

Fire Resistance |

Incombustibility A Class(GB8624-A) |

||

|

Thermal Conductivity |

Average≤0.20W/m.k |

||

|

Bending Strength |

Transverse≥11.0N/mm 3 , Vertical≥8.5N/mm 3 |

||

|

Radioactivity |

Conforming to GB6566-2001 A Class |

||

|

Asbestos |

100% Asbestos Free |

||

|

Freeze Resistance |

No distortion after 25 repeated cycles of freezing and thawing |

||

|

Certification |

SGS |

||

Partition Drywall Series

Fiber Cement Board Gypsum Board Magnesium Oxide Board Metal Profiles

Calcium Silicate Board

Partition Installing Method

1. Galvanized Metal Frame

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with

laterally supporting keel installed.

2. Board Material Package Fixed

a.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally

about 200~250mm with screws sinking 0.5mm under the board face.

c.The expansion seam of about 4mm between boards should be kept.

d.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously

to avoid generating inner stress to make board material bucking.

e.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

Ceiling Installing Method

1.Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.

2.Connect and fix the boom and main keel with hanging piece to make the main keel keep level position.

3.Vertically fix the sub-keel to the main keel with hanging piece; the sub-keel axis’central range is 612mm.

4.Install the laterally supporting keel properly, its central ranges is 1224mm.

5.Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Notice:

The hanging system of TITAN board combined with light steel keel is divided into two kinds of person-standing type

and non person-standing type; for the non person-standing type,only consider the self-weight of ceiling and light. Lamp

without loading other loads; for the person-standing type. Consider about 80~100kg load when someone repaired it.

Accessories

Calcium Silicate Board

|

Product Name |

Size | KGS | 20 GP |

|

Fiber Cement Board |

1220×2440 ×6 mm | 24 | 900 PCS |

| 1220×2440 ×8 mm | 32 | 678 PCS | |

| 1220×2440 ×10 mm | 40 | 540 PCS | |

| 1220×2440 ×12 mm | 48 | 450 PCS | |

| 1220×2440 ×15 mm | 60 | 360 PCS | |

| 1220×2440 ×18 mm | 72 | 300 PCS |

Calcium Silicate Board