- Product Details

- {{item.text}}

Quick Details

-

Use:

-

welding machine

-

Voltage:

-

AC220V

-

Dimensions:

-

L250xW180xH20mm

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

700W

-

Current:

-

Alternating curreent

-

Weight (KG):

-

16 KG

-

Product name:

-

Reflow Soldering Oven

-

Power Supply:

-

AC220V

-

Max Power:

-

3600W

-

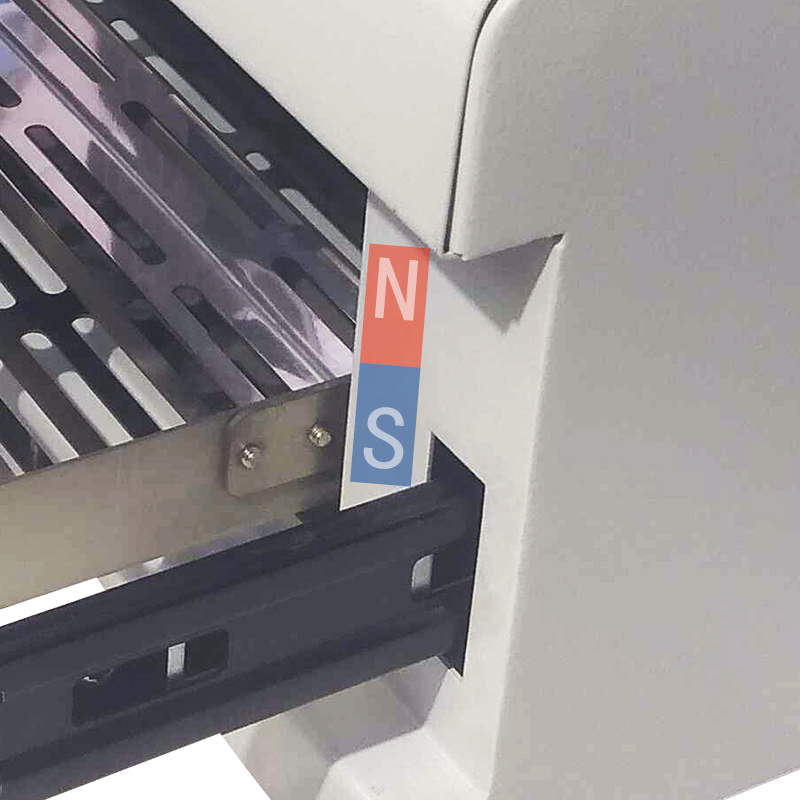

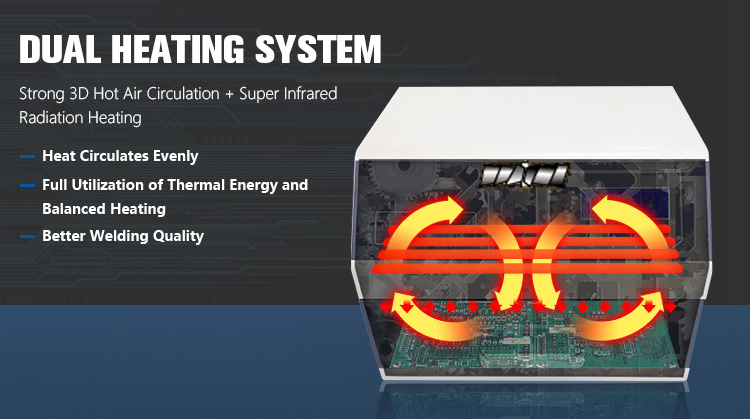

Heating Method:

-

Infrared Radiation Heating & Hot Air Circulation

-

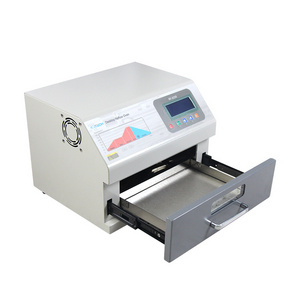

Effective Welding Area:

-

250mm*200mm

-

Drawer Size:

-

300*250*30mm

-

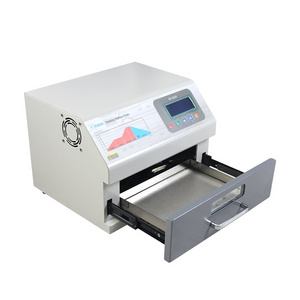

Outline Size:

-

425*400*312 mm

-

Operating System:

-

Chinese and English Bilingual Language Operate System

-

Certification:

-

CE

Quick Details

-

Applicable Industries:

-

smt pcb Reflow Solders

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ITECH

-

Use:

-

welding machine

-

Voltage:

-

AC220V

-

Dimensions:

-

L250xW180xH20mm

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

700W

-

Current:

-

Alternating curreent

-

Weight (KG):

-

16 KG

-

Product name:

-

Reflow Soldering Oven

-

Power Supply:

-

AC220V

-

Max Power:

-

3600W

-

Heating Method:

-

Infrared Radiation Heating & Hot Air Circulation

-

Effective Welding Area:

-

250mm*200mm

-

Drawer Size:

-

300*250*30mm

-

Outline Size:

-

425*400*312 mm

-

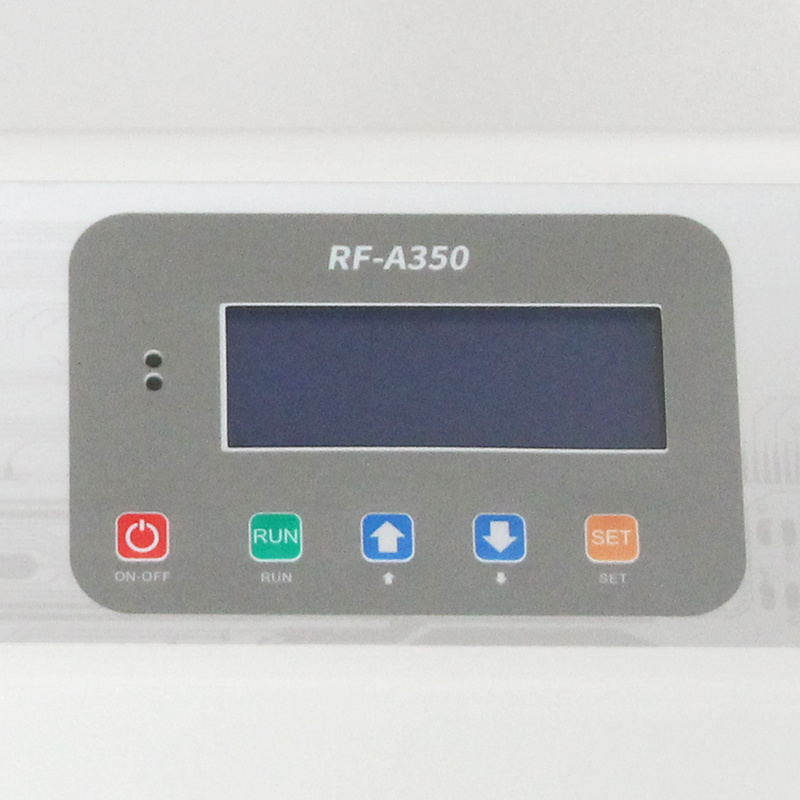

Operating System:

-

Chinese and English Bilingual Language Operate System

-

Certification:

-

CE

Products Details

Products Description

Reflow Soldering Oven

ITECH series reflow furnace is mainly for the production and maintenance of SMT products such as desktop solder reflow equipment. The product uses high efficiency far infrared heating elements and distributed thermocouple temperature measurement device. Through the microcomputer's precise control, the temperature of the reflow oven curve control can be more accurate, and the temperature of the reflow plane can be more uniform. ITECH series reflow furnace is fully able to adapt to a variety of different alloys and lead-free solder reflow requirements. Its temperature curve precision can be adjusted; in addition, this kind of equipment also has automatic fault detection alarm and other functions. This product has a variety of applications such as reflow soldering, repair, drying and so on. It's suitable for small quantities of SMT electronic products production, test research, electronic product development, school training courses and other units. This operating software is Chinese and English bilingual operating system developed independently by HuaQi Zhengbang. The structure of the circuit adopts high efficiency, convenient and integrated design, adopts aluminum silicate high temperature environmental protection heat preservation cotton, has good heat preservation effect, and improves and upgrades in aspects of performance, structure and operation.

solder reflow oven

Operating Instructions:

1.The product that will process lightly puts into the even on the stage in the drawer, Close drawer, Press F1 to switch on, The automatic performance make selection of heat wave, Show current performance time,the enactment temperature and measure temperature on the LCD screen, and the automatic formation order form wave.

2. Observed the data,wave of the window and the LCD screen manifestation before passing drawer, in the whole supervision that processed all of process and can see at you, if the request for processing wave to could not reach you can modification parameter.

3. Process the wave is strict to press the different tin syrup different temperature to have pre-established request to the return solder , you can prepare to establish another wave according to the different need.

4.Process process in, if need stop, can press "S" to carry on to terminate compulsory;After put the last hand, the breeze machine auto carries on cooling to the product;You can also start the breeze machine to carry on cooling compulsory.

5. After returning solder completion, If the product existence blemish.can solder again, Can also move the start heating to carry on returning to solder. This machine establishes this function.

|

Model

|

|

reflow oven soldering

|

|

|

|||

|

Power Supply

|

|

AC220V±10% 50Hz (AV110V Custom-Made)

|

|

|

|||

|

Operating System

|

|

Chinese and English Bilingual Language Operate System

|

|

|

|||

|

Display Mode

|

|

Graph Mode/Text Mode and Display Mode Optional

|

|

|

|||

|

Key Selling Points

|

|

Automatic

|

|

|

|||

|

Net weight

|

|

13.5KG/19KG/24.9KG/34.1KG

|

|

|

|||

|

After-sales Service Provided

|

|

Online support

|

|

|

|||

Recommend Products

About Us

Zhe Jiang HuaQi ZhengBang Electronic Equipment Co., Ltd

Zhe Jiang

HuaQi ZhengBang

Electronic Equipment Co., Ltd is a professional manufacturer specializing in research,development, production, marketing and service of soldering welding machines.

We are the leader of soldering machines supplier, our main products are Solder Paste Mixer, Silk Screen Printing Machines, Pick And Place Machine, Reflow Oven, Heating Plate, Dip Soldering Machines, SMT Inspection Conveyor, SMT upper and bottom stock frames, Turnover Cart, Feeder, Nozzles, Soldering Pot, PCB cutting machine, Sharpen Machine and so on. Most our products have passed CE certification and lots of products got patent.

Our products have won a good reputation all over the world, We’re sincerely looking forward to serving you in the nearest future.

Hot Searches