- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

decided by model

-

Weight:

-

1200, 1200 kg

-

control:

-

automatic control

-

heating plate:

-

Q-235 steel

-

cylinder:

-

cast steel

-

mold closing force:

-

25Ton/50Ton/80Ton/100Ton,etc

-

size of heating plate:

-

according to the request

-

Power(W):

-

2.2 kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

jucai

-

Voltage:

-

as your local need

-

Dimension(L*W*H):

-

decided by model

-

Weight:

-

1200, 1200 kg

-

control:

-

automatic control

-

heating plate:

-

Q-235 steel

-

cylinder:

-

cast steel

-

mold closing force:

-

25Ton/50Ton/80Ton/100Ton,etc

-

size of heating plate:

-

according to the request

-

Power(W):

-

2.2 kw

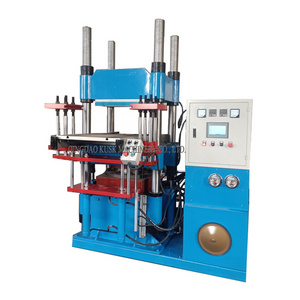

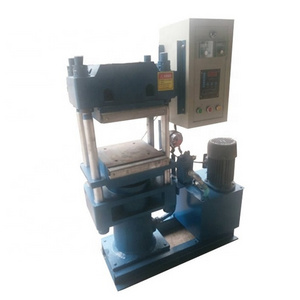

Product Application

This machine consists of main machine , an electrical cabinet and a hydrualic station . The machine is in pillar structure and has two working layers .It is widely used for heating , vulcanizing , and solidifying various kinds of rubber molded products , such as seal , o ring , gasket and similar products. it is also widely used in lab production use .

Main Features

1.The cylinder ( piston ) adopts the best seals structure , with reasonable design and reliable function. The seals part is good quality YX type polyurethane seals (not rubber seal ) ,which is oil resistant , aging resistant .Our machine adopts the double seals structure , and seals part is easy change and protect.

2. Automatic control : automatic mold closing , automatic exhausting , automatic heating and keep stable temperature, automatically timing for vulcanization , automatic alarming , automatic mold opening ,etc . kindly note we are automatic control , not semi-automatic control

3.The temperature can be set in the electrical cabinet . For example , if you need 250 C , just set250 C in the temperature control panel .When it reaches your aimed temperature , the temperature will stop to rise and keep stable.Sensor are installed in the heating plate and connect with the temperature indicator in the heating plate . It will show clear the temperature of every heating plate

4.Vulcanizing time can be set in the time relay . If you want to heat and vulcanize for 30 minutes , just set it directly . When it reaches 30 minutes ,machine will alarm then machine will automatic open the mold

5.The pillar is made of high quality # 45 cast steel . The hardness , wear resistance and abrasive resistance is high improved by quenching and tempering

6.The top beam and bottom plate form is welded with the good quality Q-235A ductile iron .After welding , it is also processed by the artificial vibration or high temperature aging treatment , to eliminate the internal stress and avoid the deformation

7.plunger is made of LG-P cold hard alloy steel . Surface of it owns high hardness and wear resistant.Depth of chilled layer is 8-15mm , hardness is HRC 60-70 , making the plunger own long life time

8.Heating plate is made of Q-235A ductile iron , It is processed by the high temperature aging treatment

9.Our cylinder is made of cast steel , which can resist higher hydraulic system pressure compared with traditional cold cast iron cylinder . Our cylinder is much longer in life time rather than traditional cylinder

10.hydraulic station adopts the best china brand for long life time

|

Model

|

XLB-350*350 /25T

|

XLB-400*400/50T

|

XLB-450*450/50T

|

|

mold closing force

|

25T

|

50T

|

50T

|

|

plate size

|

350*350

|

400*400

|

450*450

|

|

working layer

|

1/2

|

1/2

|

1/2

|

|

daylight

|

200mm

|

200mm

|

200mm

|

|

stroke

|

200/400mm

|

200/400mm

|

200/400mm

|

|

control

|

automatic control

|

automatic control

|

automatic control

|