- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PRECITURN

-

Product Name:

-

Boring Tool

-

Advantage:

-

High Eficiency

-

Usage:

-

CNC Lathes

Quick Details

-

Type:

-

boring tool

-

Diameter:

-

CUSTOM

-

Material:

-

CUSTOM

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

PRECITURN

-

Product Name:

-

Boring Tool

-

Advantage:

-

High Eficiency

-

Usage:

-

CNC Lathes

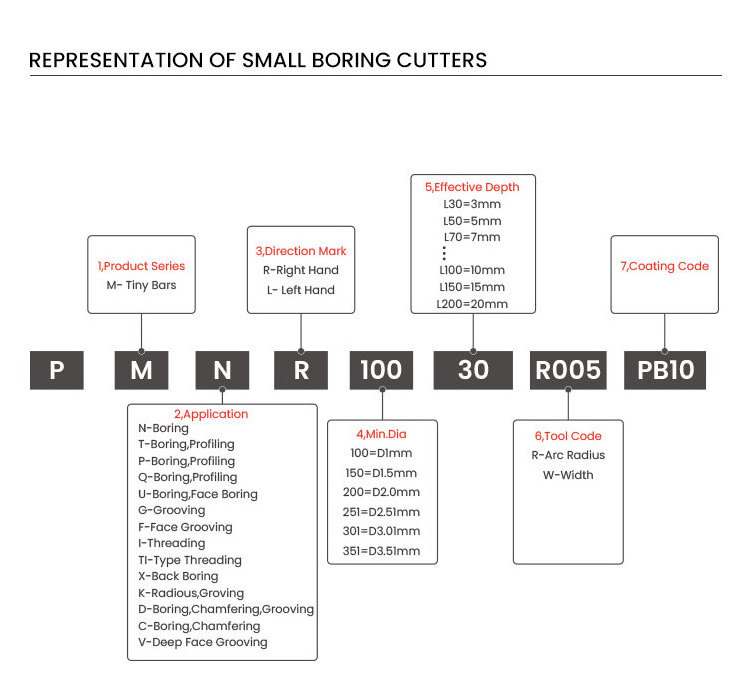

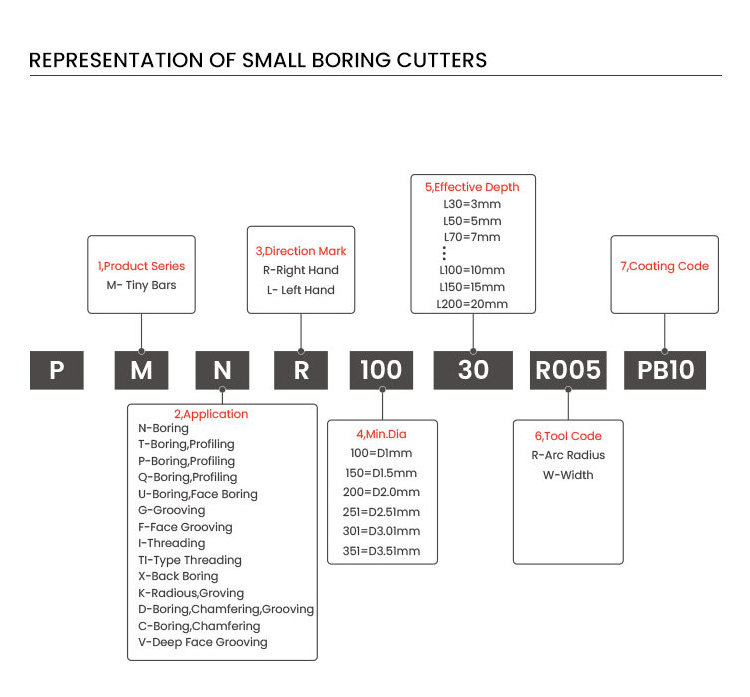

ID MicroBoring Tools

Support customization

PRECITURN Micro Bore Tools families are available for small internal diameter turning. Especially for Sliding Head Swiss type Machines.

Micro bore tools are made from solid carbide with option coating,like TIN,ALTIN,HELICA,AlCrN,TIALSiN,Diamond and more, these different coating has different composition and feature, using in various material and situation. We will accoring to customer machine situation to give best option solution.Micro boring tools are basic use PVD coating methods.

Preciturn solid carbide micro bore bar are special for high precision and finishing process.Our micro bore cutters have features like Durable, wear assistant,high performance.

Also we can customize various geometry of cutting part and holding part for various brands.

We welcome you to contact us to give you best solution for you turning requirments.

|

Grades

|

Application Material

|

Micro Bore Families

|

Process(ID)

|

|

PB10

|

High performance with a wide range of Stainless include austenitic&Martensite, 303,304,316,321,Nickel alloy.

|

PMNR/L

|

Boring

|

|

|

|

PMTR/L

|

Boring,Profiling

|

|

|

|

PMPR/L

|

Boring,Profiling

|

|

|

|

PMUR/L

|

Flat-bottom,Boring,Profiling

|

|

PB20

|

Universal use for ≤HRC55 material; Extremely high heat resistance for high heat treated steel & High hardness steel For example

:Superalloy,Bearing steel,quenched steel,Cr-Mo stee,Mn steel.cast iron |

PMQR/L

|

Boring,Profiling

|

|

|

|

PMGR/L

|

Grooving

|

|

|

|

PMFR/L

|

Face Grooving

|

|

PB30

|

|

PMIR/L

|

Threading

|

|

|

|

PMXR/L

|

Back Boring

|

|

|

|

PMKR/L

|

Radious Grooving

|

|

|

|

PMDR/L

|

Boring,Chamfering,Grooving

|

|

PB40

|

|

PMCR/L

|

Boring,Chamfering

|

|

|

|

PMTIR/L

|

Threading

|

|

|

|

PMVR/L

|

Face Grooving

|

PRODUCT PARAMENTERS

|

Product Name:

|

Tungsten Steel Boring Tool

|

|

Grade :

|

PB10, PB20,PB30,PB40.PVD Coating

|

|

Blade Material:

|

Tungsten Steel

|

|

Applicable Processing:

|

Professional Boring/ Turning Inner Circle Processing

|

|

Applic Able Processing Materials:

|

Stainless Steel, Steel, Iron,Aluminum Alloy, Etc.

|

|

Machining Type:

|

Boring Tool

|

|

Suitable For Machine Tools:

|

CNC Sliding Head Lathes,Swiss Automatic Lathe, Swiss Auto Lathe

|

|

Product Features:

|

1. Smooth Chip Evacuation And Fficient Machining

2. The Boring Tool Is Integrally Formed

3. Imported Machine Tool Precision Grinding

4. Nano Coating Is Wear-Resistant And Durable

5. With Fixed Flat Position

|

DETAILS IMAGES

OUR COMPANY

FACTORY

QUALITY GUARANTEE

EXHIBITION & CUSTOMER

CERTIFICATION

PAYMENT / SHIPPING

FAQ

Q1.

Are you manufacturer or trading company?

A1: We are professional manufacturer with more than 16 years.

And we have comprehensive cutting tools in Turning, Threading,Milling,Drilling etc.

Q

2

.

Why we can choose you?

A2: 1、Excellent and stable products quality : Over 16 years of experiences in carbide cutters development and manufacture

2、6 Production lines with 45 production machine and many quality control and testing machine.

3、A team of more than 20 engineers, including 8 senior engineers, capable of providing complex and innovative processing solutions.

4、Short lead times, Customized carbide inserts and other cutters can be 3-5 days

5、Professional international trade team, successfully expanding our product reach to various countries in Southeast Asia, Europe, South America, and beyond.

Q

3.

How to place an order?

A3: 1.Fill your Order List in our online Inquiry System.

2.Directly contact our salesperson by E-mail / Skype / Whats App

We will make a feedback to you ASAP after receive your order list.

Q

4.

How about the delivery time?

A4: 1、standard in stock usually 2days after payments.

2、non standard cutting tools usually 5-7 days for producing, non standard inserts sometimes can be 3-5days

3、big order in standard or non-standard, depends on qty and drawing.

CONTACT US

Hot Searches