- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ODMT

-

Model Number:

-

YFJ-D600

-

Product name:

-

valve test bench

-

Color:

-

black

-

Material:

-

Stainless Steel

-

Test Medium:

-

Oil /Water/gas

-

Type:

-

portable/ computer control

-

Temperature range:

-

customized

-

Model:

-

MHV-B300/40

-

Application:

-

safety valve test

-

Power supply:

-

380V 50Hz

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

250W

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ODMT

-

Model Number:

-

YFJ-D600

-

Product name:

-

valve test bench

-

Color:

-

black

-

Material:

-

Stainless Steel

-

Test Medium:

-

Oil /Water/gas

-

Type:

-

portable/ computer control

-

Temperature range:

-

customized

-

Model:

-

MHV-B300/40

-

Application:

-

safety valve test

-

Power supply:

-

380V 50Hz

Product Description

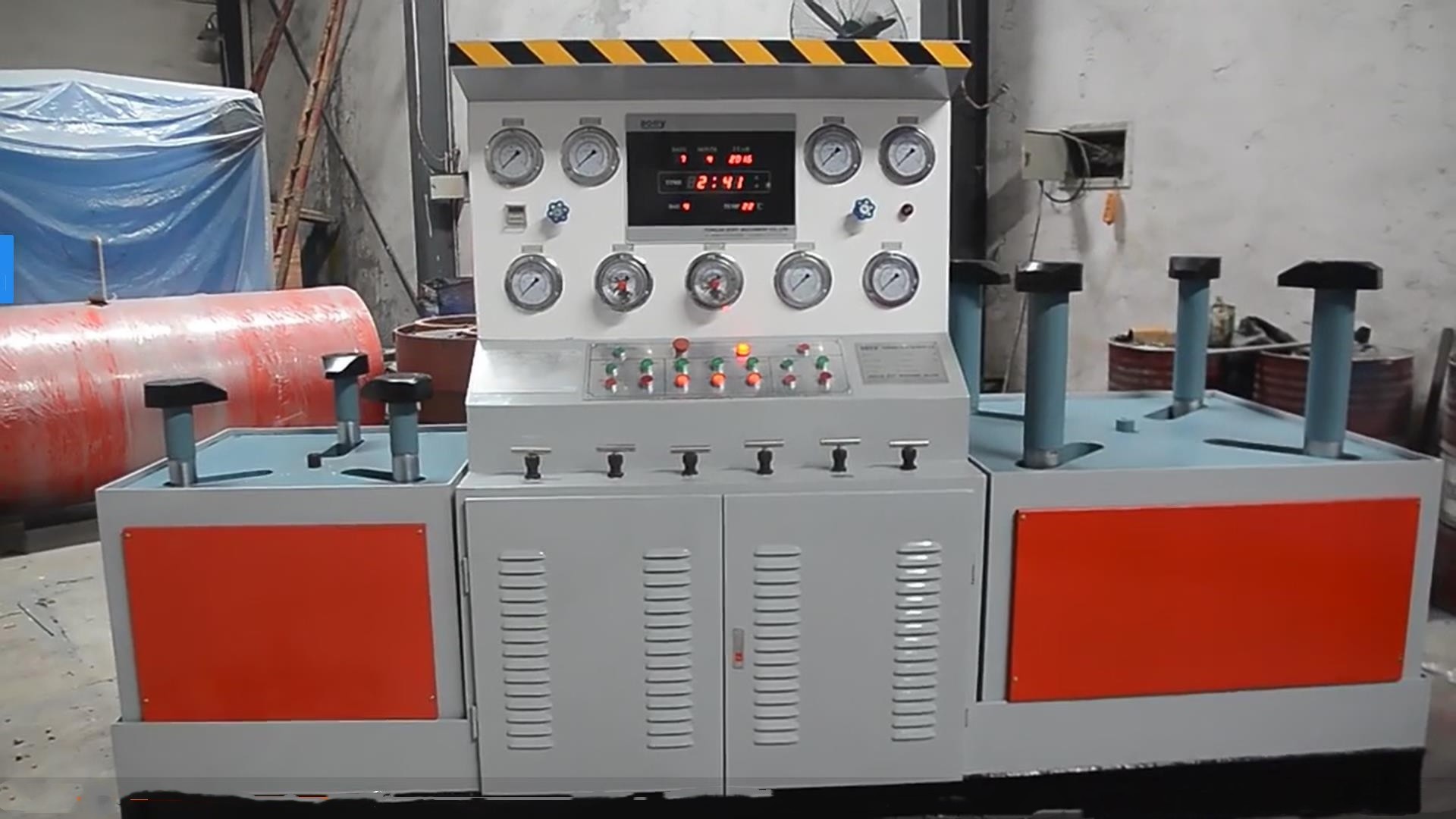

YFJ-D600 type hydraulic butterfly valve test bench is based on our years of production of valve testing equipment technology instrict accordance with the ISO9001 quality management system for management and production. Products meet GB/T13927-2008"Universal valve pressure test", GB/T26480-2011 "valve test and inspection" and AP1598 American standard and other relevantstandards.

Our hydraulic butterfly valve test bench set hydraulic, mechanical, electrical and media storage cycle combination in one, has the advantages of reasonable structure, perfect function, stable performance, high degree of automation, widely used in nominal diameter DN50-600mm straight flange or clamp butterfly valve sealing and strength and other performance tests, Is the valve manufacturing, petroleum and petrochemical, natural gas, water supply and drainage engineering, power plant, valve maintenance station and other industry units the most ideal valve test and testing equipment.

II.Butterfly Valve Test bench Structure and Working Principle

1. hydraulic butterfly valve test bench consists of hydraulic system, electrical control system, high and low pressure water

pump pressure supply device system, oil pressure, water pressure instrument system, control valve system, clamping work bench system and hydraulic medium storage circulating water tank. The test process and results conform to relevant regulations and requirements.

2.The test bench uses the clamping claw to directly clamp the opposite flange surface of the butterfly valve, and the clamping mechanism is directly driven by the clamping cylinder of the clamping claw to work. The clamping claw can move forward and backward in the axial direction without being limited by the thickness. The radial movement is composed of oil cylinder and lever to realize the radial synchronous movement of each clamping claw, and the radial clamping claw can move forward and backward It is not limited by the flange diameter of butterfly valve. The test bench is divided into single type and combined type according to the valve specifications, which ensures butterfly valves of different sizes and diameters, wafer check valves, strength performance tests and air tightness performance tests.

3.The high-pressure water pump is powered by a 4-7bar air pressure system, and automatically reverses through an electric control reversing valve to enable the high-pressure water pump to automatically reciprocate. The water suction check valve and water outlet check valve are interchanged to continuously supply pressure to the valve under test to meet the pressure requirements of the valve under test.

4.It is applicable to flange butterfly valve and wafer butterfly valve 1.1 times nominal pressure high pressure water seal test, 1.5 times nominal pressure high pressure water shell test, 4-7bar low pressure air seal test.

Our hydraulic butterfly valve test bench set hydraulic, mechanical, electrical and media storage cycle combination in one, has the advantages of reasonable structure, perfect function, stable performance, high degree of automation, widely used in nominal diameter DN50-600mm straight flange or clamp butterfly valve sealing and strength and other performance tests, Is the valve manufacturing, petroleum and petrochemical, natural gas, water supply and drainage engineering, power plant, valve maintenance station and other industry units the most ideal valve test and testing equipment.

II.Butterfly Valve Test bench Structure and Working Principle

1. hydraulic butterfly valve test bench consists of hydraulic system, electrical control system, high and low pressure water

pump pressure supply device system, oil pressure, water pressure instrument system, control valve system, clamping work bench system and hydraulic medium storage circulating water tank. The test process and results conform to relevant regulations and requirements.

2.The test bench uses the clamping claw to directly clamp the opposite flange surface of the butterfly valve, and the clamping mechanism is directly driven by the clamping cylinder of the clamping claw to work. The clamping claw can move forward and backward in the axial direction without being limited by the thickness. The radial movement is composed of oil cylinder and lever to realize the radial synchronous movement of each clamping claw, and the radial clamping claw can move forward and backward It is not limited by the flange diameter of butterfly valve. The test bench is divided into single type and combined type according to the valve specifications, which ensures butterfly valves of different sizes and diameters, wafer check valves, strength performance tests and air tightness performance tests.

3.The high-pressure water pump is powered by a 4-7bar air pressure system, and automatically reverses through an electric control reversing valve to enable the high-pressure water pump to automatically reciprocate. The water suction check valve and water outlet check valve are interchanged to continuously supply pressure to the valve under test to meet the pressure requirements of the valve under test.

4.It is applicable to flange butterfly valve and wafer butterfly valve 1.1 times nominal pressure high pressure water seal test, 1.5 times nominal pressure high pressure water shell test, 4-7bar low pressure air seal test.

Part of Machine

Specification

|

Technical Parameter

|

Left Workbench

|

Right Workbench

|

|

Test range

|

DN50-250

|

DN250-600

|

|

Test butterfly valve structure length

|

43-250mm

|

165-390mm

|

|

Diameter of tested butterfly valve flange

|

Ф 165-425mm.

|

Ф405-845mm

|

|

Claw disc spacing

|

200-400mm

|

480-800mm

|

|

Clamping oil cylinder

|

3XФ100mm

|

4XФ160mm

|

|

Piston rod

|

3XФ60mm

|

4XФ90mm

|

|

Maximum clamping force

|

40 Tons

|

150 Tons

|

|

Left Workbench

|

|

|

Right Workbench

|

|

|

||||

|

Applicable to DN50-250 wafer type or flange type butterfly valve

|

|

|

Applicable to DN250-600 wafer type or flange type butterfly valve

|

|

|

||||

|

Diameter

|

Work Pressure

|

Test pressure range

|

Diameter

|

Work Pressure

|

Test pressure range

|

||||

|

DN50-65

|

1.6-10.0Mpa

|

1.6-15.0MPa

|

DN250

|

1.6-10.0MPa

|

1.6-15.0MPa

|

||||

|

DN80

|

1.6-10.0Mpa

|

1.6-15.0MPa

|

DN300

|

1.6-10.0MPa

|

1.6-15.0MPa

|

||||

|

DN100

|

1.6-10.0Mpa

|

1.6-15.0MPa

|

DN350

|

1.6-6.4 MPa

|

1.6-9.6 MPa

|

||||

|

DN125

|

1.6-10.0Mpa

|

1.6-15.0MPa

|

DN400

|

1.6-5.0 MPa

|

1.6-7.5 MPa

|

||||

|

DN150

|

1.6-6.4 Mpa

|

1.6-9.6 MPa

|

DN450

|

1.6-4.0 MPa

|

1.6-6.0 MPa

|

||||

|

DN200

|

1.6-5.0 Mpa

|

1.6-7.5 MPa

|

DN500

|

1.6-2.5 MPa

|

1.6-3.75 MPa

|

||||

|

DN250

|

1.6-2.5 Mpa

|

1.6-3.75 MPa

|

DN600

|

1.6-2.5 MPa

|

1.6-3.75 MPa

|

||||

|

Test valve type

|

straight through flange gate valve

|

|

|

Butterfly Valve

|

|

|

check valve

|

|

Clamping method

|

the clamping jaws clamp the back of the flange

|

|

Valve and blind plate sealing method

|

O-ring seal on the end face

|

|

Pressure test medium

|

water (air or nitrogen)

|

|

Test range

|

DN50-300, see the pressure test range table

|

|

Test valve structure length

|

203-750mm

|

|

Test valve flange diameter

|

190-520mm

|

|

Test valve flange thickness

|

20-83mm

|

|

Working disc spacing

|

250-1100mm

|

|

Left and right clamping cylinders

|

3X140mm

|

|

Maximum clamping force

|

100 tons

|

|

data acquisition software

|

LABVEIW program

|

|

pressure sensor adopts

|

German IFM

|

|

acquisition card adopts

|

American NI

|

Company Profie

Why Choose Us

FAQ

Q1

:Are you the manufacturer?

A1

:Yes , we are the manufacturer of the valve test bench and valve grinding machine, located in

jinan,shandong. We have our own brand :ODMT and Hailaitaide.

Q2 : Do you have any certificates?

A2 : Yes, we have CE, ISO .

Q3 : Do you offer installation and comissioning services ?

A3 : Yes. we have, Our engineer has been visiting to India, USA, Italy, Saudi, Indonesia, Singapore, South Africa etc

Q4 : Can you customize the machine?

A4 : Yes, please send us by email all your request.

jinan,shandong. We have our own brand :ODMT and Hailaitaide.

Q2 : Do you have any certificates?

A2 : Yes, we have CE, ISO .

Q3 : Do you offer installation and comissioning services ?

A3 : Yes. we have, Our engineer has been visiting to India, USA, Italy, Saudi, Indonesia, Singapore, South Africa etc

Q4 : Can you customize the machine?

A4 : Yes, please send us by email all your request.

Hot Searches