- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China, Shandong, China

-

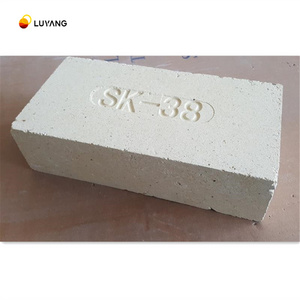

Model Number:

-

LYFCB, Fire Clay Brick

-

Brand Name:

-

LUYANG

-

Al2O3 Content:

-

35%-40%

-

Bulk density g/cm3::

-

2.00-2.35

-

Color::

-

Yellow

-

Certificate:

-

ISO9001

-

Usage:

-

Furnace Liner

-

HS code:

-

6902.2000

Quick Details

-

SiO2 Content (%):

-

<0.5~8.0

-

Al2O3 Content (%):

-

35-52%

-

MgO Content (%):

-

0

-

CaO Content (%):

-

0

-

CrO Content (%):

-

0

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China, Shandong, China

-

Model Number:

-

LYFCB, Fire Clay Brick

-

Brand Name:

-

LUYANG

-

Al2O3 Content:

-

35%-40%

-

Bulk density g/cm3::

-

2.00-2.35

-

Color::

-

Yellow

-

Certificate:

-

ISO9001

-

Usage:

-

Furnace Liner

-

HS code:

-

6902.2000

Product Description

Fire clay brick is made of local top grade fireclay materials under the high temperature according to the lasted national

standard, which possesses even bulk density, high strength, low thermal conductivity and low impurity. Fire clay refractory brick has wide usage and the largest production.

Features Of Fire Clay Brick

Good performance in high temp refractoriness under load

Lower thermal line expansion in high temp

Lower impurity content

Good thermal shock resistance performance

Excellent resistance in slag abrasion

Good cold crush strength

Applications Of Fire Clay Brick

-Reheating Furnace

- Blast furnace

- General Industrial Furnace etc.Blast Furnace,

-Coke Oven,Topedo Car,

-Cement Rotary kiln, Various Rotary kiln,

-Chemical Reactor, incinerator, Non Ferreous, metal Furnace,

-Glass furnace

Specifications Of Fire Clay Brick

Hard Fire Clay Bricks

Alumina contents range from 35% to 45%

Widely used throughout metallurgical industry

standard, which possesses even bulk density, high strength, low thermal conductivity and low impurity. Fire clay refractory brick has wide usage and the largest production.

Features Of Fire Clay Brick

Good performance in high temp refractoriness under load

Lower thermal line expansion in high temp

Lower impurity content

Good thermal shock resistance performance

Excellent resistance in slag abrasion

Good cold crush strength

Applications Of Fire Clay Brick

-Reheating Furnace

- Blast furnace

- General Industrial Furnace etc.Blast Furnace,

-Coke Oven,Topedo Car,

-Cement Rotary kiln, Various Rotary kiln,

-Chemical Reactor, incinerator, Non Ferreous, metal Furnace,

-Glass furnace

Specifications Of Fire Clay Brick

Hard Fire Clay Bricks

Alumina contents range from 35% to 45%

Widely used throughout metallurgical industry

|

Material

|

fire clay material

|

|

Color

|

earthy yellow

|

|

Size

|

Standard sizing: 230 x 114 x 65 mm ,Special size and OEM Service also provide!

|

|

Shape

|

Straight Brick,special-shaped brick,checher brick,trapezoidal brick,Bricks with taper,arch brick,skew brick,ect.

|

Specification

|

Item/Grade

|

Fire clay brick

|

|

|

|

|||

|

|

SK-30

|

SK-32

|

SK-34

|

SK-35

|

|||

|

AL2O3% (≥)

|

30

|

35

|

38

|

45

|

|||

|

Fe2O3% (≤)

|

2.5

|

2.5

|

2

|

2

|

|||

|

Refractoriness(SK)

|

30

|

32

|

34

|

35

|

|||

|

Refractoriness under load, 0.2MPa, °C (≥)

|

1250

|

1300

|

1360

|

1420

|

|||

|

Apparent porosity (%)

|

22-26

|

20-24

|

20-22

|

18-20

|

|||

|

Bulk density (g/cm³)

|

1.9-2.0

|

1.95-2.1

|

2.1-2.2

|

2.15-2.22

|

|||

|

Cold crushing strength ,MPa (≥)

|

20

|

25

|

30

|

40

|

|||

Application

|

Iron & steel making industry

|

Blast furnace, hot blast furnace(stove), pellet shaft furnace, hot metal ladle, steel ladle, tundish, eating furnace, soaking pit furnace, heat treatment furnace, refining furnace, reheating furnace, metal mixter furnace, cupola furnace etc thermal technology equipment.

|

|

Non-ferrous Metal industry

|

Smelting furnace, reverberatory furnace etc.

|

|

Building materials industry

|

Cement kiln, glass kiln, ceramic kiln, lime kilns, kiln car, tunnel kiln, rotary kiln.

|

|

Energy&Incineration

|

Coke oven, general boiler, power generation boiler, circulating fluidized bed boiler, electric furnace, carbon roasting furnace, waste incinerators

|

|

Others

|

Petrochemical industry furnace, Pizza oven

|

Packing & Delivery

Our service

1. Strict QC & Fast delivery.2. Free samples are available by freight collect.

3. High quality goods, Perfect Pre-sales, and good designing service.

4. Welcome to visit our factory at anytime on site or online .

5. We will update you the production process after placing order by photos or online.

6. We have special after-sales team to solve your problem during using our products.

3. High quality goods, Perfect Pre-sales, and good designing service.

4. Welcome to visit our factory at anytime on site or online .

5. We will update you the production process after placing order by photos or online.

6. We have special after-sales team to solve your problem during using our products.

Hot Searches