- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TFZD

-

Voltage:

-

Customize

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

150 KG

-

Color:

-

Customize

-

Material:

-

Customize

-

Layer(s):

-

Customize

-

Advantage:

-

High Precision

-

Machine type:

-

Automatic

-

Mesh size:

-

Customize

-

Diameter:

-

Customize

-

Installation:

-

Convenient

-

Operation:

-

Easy

-

Product Name:

-

vibrating sifter

Quick Details

-

Type:

-

Rotary type

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TFZD

-

Voltage:

-

Customize

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

150 KG

-

Color:

-

Customize

-

Material:

-

Customize

-

Layer(s):

-

Customize

-

Advantage:

-

High Precision

-

Machine type:

-

Automatic

-

Mesh size:

-

Customize

-

Diameter:

-

Customize

-

Installation:

-

Convenient

-

Operation:

-

Easy

-

Product Name:

-

vibrating sifter

Product Description

Coconut Milk Vibrating Filter High-quality Rotary Vibrating Screen Machine

Product Introduction

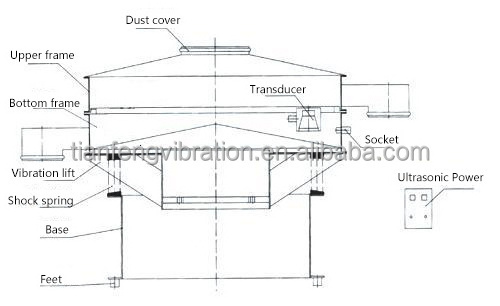

Tianfeng TS series ultrasonic vibrating screen can screen heavy, light, superfine and strongly adsorbent powder which can not been screened by regular vibrating screen. The ultrasonic vibrating screen can process all fine powder which can not been screened easily. The ultrasonic vibrating screen is similar to regular vibrating screening and filtering machine, and the difference between them is ultrasonic vibrating screen is equipped with ultrasonic device system. Through ultrasonic power supply and ultrasonic transducer, the ultrasonic vibrating screen can convert ultrasonic wave into mechanical wave with high frequency and convey the wave to screen surface so that the raw material on screen surface can be screened very well. Generally speaking, the screening and passing rate of ultrasonic vibrating screen is higher than the screening and passing rate of regular vibrating screen.

Technical Characteristics

1. The ultrasonic vibrating screen has perfect screening ability and more accurate screening precision, and it can achieve the screening with high precision. The screening precision can be increase by 1-70%, and the capacity can be increased by 0.5-10 times.

2. The problem of the screen net can be blocked by raw material easily can be solved efficiently. The raw material can not block screen net, and it can be controlled in a narrow range of particle size.

3. The equipment can efficiently solve the problem that some raw material can not be screened easily such as strongly adsorbent powder, easy to gathered materials, high electrostatic materials and light gravity materials.

4. The equipment can ensure the characteristics of the materials can not be changed easily.

5. The ultrasonic vibrating screen adopts digital signal inputing system, and it can achieve automatic frequency tracking.

6. The energy conversion efficiency of transducer is high(reaching the standard of foreign counterparts).

7. The equipment can continuously work for 24h. The power supply for controlling equipment and the transducer do not need to cool down.

8. For unloading, loading, and cleaning conveniently, the contact between transducer and screen net adopts screws.

9. The equipment adopts separating structure and resonance ring. The screening efficiency is excellent, and the service life of screen net is long.

10. The equipment can screen the particles or the powder with 25μ and the liquid or the mucus with 10μ.

11. The equipment do not need rubber ball to clean screen net, and that can efficiently avoid the contamination caused by the wearing of rubber ball.

12. The equipment adopts adhesive screen net to fix screen frame, no pollution, no dead angle, uniform power, easy to replace.

2. The problem of the screen net can be blocked by raw material easily can be solved efficiently. The raw material can not block screen net, and it can be controlled in a narrow range of particle size.

3. The equipment can efficiently solve the problem that some raw material can not be screened easily such as strongly adsorbent powder, easy to gathered materials, high electrostatic materials and light gravity materials.

4. The equipment can ensure the characteristics of the materials can not be changed easily.

5. The ultrasonic vibrating screen adopts digital signal inputing system, and it can achieve automatic frequency tracking.

6. The energy conversion efficiency of transducer is high(reaching the standard of foreign counterparts).

7. The equipment can continuously work for 24h. The power supply for controlling equipment and the transducer do not need to cool down.

8. For unloading, loading, and cleaning conveniently, the contact between transducer and screen net adopts screws.

9. The equipment adopts separating structure and resonance ring. The screening efficiency is excellent, and the service life of screen net is long.

10. The equipment can screen the particles or the powder with 25μ and the liquid or the mucus with 10μ.

11. The equipment do not need rubber ball to clean screen net, and that can efficiently avoid the contamination caused by the wearing of rubber ball.

12. The equipment adopts adhesive screen net to fix screen frame, no pollution, no dead angle, uniform power, easy to replace.

Main Material

1. Carbon Steel

2. Semi-Stainless Steel

3. Stainless Steel

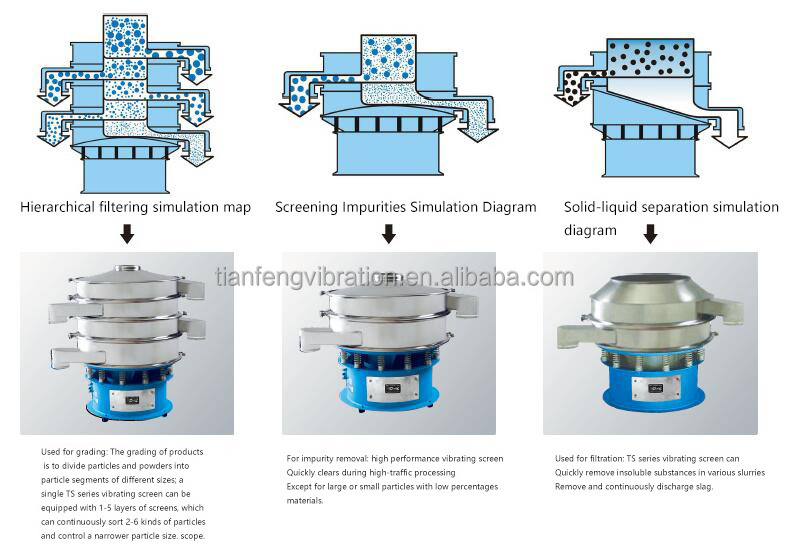

Main Function

1. Screening and grading

2. Removing impurities

3. Separating between solid materials and liquid materials

Applicable Industries

TS series ultrasonic vibrating screen can be used for screening silicon carbide, brown corundum, white corundum, molybdenum powder, tungsten powder, cobalt powder, nickel powder, stainless steel powder, alloy powder, powder coating, quartz powder, diamond powder, electromagnetic powder, laser powder, aluminum powder, electrolytic copper powder, grinding powder, refractory materials, luminous powder, glass beads, rubber additives, sugar powder, starch, salt, soy milk powder, bulk drug intermediates and other various raw materials can not be screened by regular screening machine.

Main Parameters

|

Model

|

Materials

|

Screen mesh

|

Test Results

|

|

TS-1000

|

Silicon carbide

|

500

|

1000 kg/h

|

|

TS-1000

|

Tungsten carbide powder

|

600

|

30kgth

|

|

TS-1000

|

Vitamin C powder

|

100

|

120kg/h

|

Packaging&Shipping

After you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight

transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we will inform the ocean cargo transportation agent company that it is ready to come to the factory and to transport the goods to the port. On the day of delivery, we will send you the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent you from not knowing what each part is after receiving the goods. At the same time, we will put an English version of the product instructions in the cargo box. About shipping, we generally select freight forwarders with preferential prices for customers to deliver goods for you. The packaging method usually is wooden box. The shipping method usually is FOB or CIF. You can also choose EXW, and then contact the goods agent company by yourself. About packaging method and shipping method, if you have any different idea, welcome to communicate with us.

transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we will inform the ocean cargo transportation agent company that it is ready to come to the factory and to transport the goods to the port. On the day of delivery, we will send you the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent you from not knowing what each part is after receiving the goods. At the same time, we will put an English version of the product instructions in the cargo box. About shipping, we generally select freight forwarders with preferential prices for customers to deliver goods for you. The packaging method usually is wooden box. The shipping method usually is FOB or CIF. You can also choose EXW, and then contact the goods agent company by yourself. About packaging method and shipping method, if you have any different idea, welcome to communicate with us.

Company Profile

Hot Searches