- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TOPECH

-

Model Number:

-

LY-368

-

Product name:

-

Anti wear lubricants additive

-

Packing:

-

Barrels/buckets

-

Keywords:

-

Lubricant Additive

-

Function:

-

Reduce Wear

Quick Details

-

Application:

-

Automotive Lubricant

-

Type:

-

Anti wear additive

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

TOPECH

-

Model Number:

-

LY-368

-

Product name:

-

Anti wear lubricants additive

-

Packing:

-

Barrels/buckets

-

Keywords:

-

Lubricant Additive

-

Function:

-

Reduce Wear

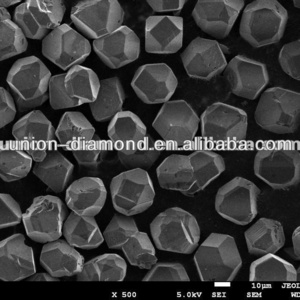

AW Nitrogen boron complex ester additive

Very light yellowish high-transparent fully synthetic oily liquid, self-developed environmentally-friendly advanced anti-wear repair agent, specially stated that it does not contain sulfur, phosphorus, chlorine, nano-powder, metal components and so on. It has anti-wear properties, extreme pressure, and extremely low friction coefficient unmatched by conventional anti-wear agents. Adopts advanced esterification technology, and the nitrogen-boron complex produced in the locomotive instantly forms a highly wear-resistant ceramicized boron nitride molecular film in molecular form due to temperature and pressure. This product successfully solved the fatal flaw in the international adoption of nano boron nitride technology! It has the functions of high efficiency, noise reduction, environmental protection, and extended locomotive life. It is especially important for metal non-selectivity and does not corrode rubber seals. Efficiently slows down the temperature rise of the lubricating oil, and performs better in high-temperature, high-speed and heavy-duty locomotives. It is one of the longest representative technologies for the longest duration of anti-wear and anti-wear!

|

Quality Index |

Test Method |

|

|

Appearance |

Very light yellowish liquid |

Visual measurement |

|

Density (20℃) / ( kg/m3 ) |

1.1-1. 25 |

GB/T1884/1885 |

|

Kinematic Viscosity (100℃) / ( mm2/s ) ( 4 0℃) / ( mm2/s ) |

11-13

120-130

|

GB/T265 |

|

Flash point ( Open cup )/℃ ≥ |

2 13 |

GB/T267 |

|

Pour point /℃ |

- 20 |

GB/T3535 |

|

H eating loss ( 125℃,3h ) /% |

0.1 |

GB/T7325 |

|

Copper corrosion (121℃,3h) / ≤ |

1 a |

GB/T50961 |

|

Load bearing ability |

4150 lbs |

|

|

Coefficient of Friction(COF) |

0.037 Dynamic |

|

|

Anti Friction area(mm) and Performance improved percent (%) |

0.35mm/ 83% |

|

|

Four ball machine test PB/ KG |

120 |

GB/T31421 |