- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

19000X1500X3500MM

-

Power (kW):

-

200

-

Weight:

-

4000 KG

-

Raw material:

-

PE Granules or PPR granules

-

Usage:

-

Water Pipe

-

Automatic Grade:

-

fully automatic

-

Final product:

-

PE PPR pipe

-

Color:

-

customized

-

Motor brand:

-

Siemens Beide

-

three layers PPR pipe machine:

-

three layers PPR pipe machine

-

PPH pipe production line:

-

PPH pipe production line

-

PPB co-extrusion pipe making machine:

-

PPB co-extrusion pipe making machine

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

95 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

19000X1500X3500MM

-

Power (kW):

-

200

-

Weight:

-

4000 KG

-

Raw material:

-

PE Granules or PPR granules

-

Usage:

-

Water Pipe

-

Automatic Grade:

-

fully automatic

-

Final product:

-

PE PPR pipe

-

Color:

-

customized

-

Motor brand:

-

Siemens Beide

-

three layers PPR pipe machine:

-

three layers PPR pipe machine

-

PPH pipe production line:

-

PPH pipe production line

-

PPB co-extrusion pipe making machine:

-

PPB co-extrusion pipe making machine

-

Certification:

-

CE ISO

-

Marketing Type:

-

Ordinary Product

Product Description

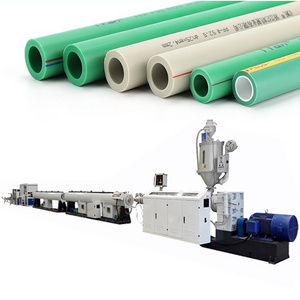

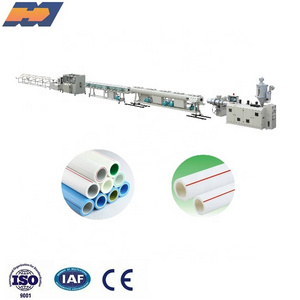

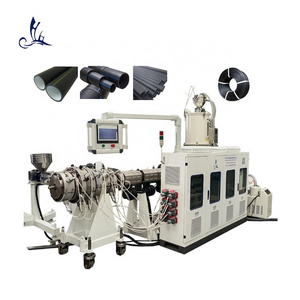

co-extrusion PPR pipe making machine production line

This PPR PP PE Pipe Machine HDPE Pipe Extrusion Machine Plastic Pipe Lline which have excellent stiffness and flexibility, heat

resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep

deformation, heat-linkage, and so on. So, it is a preferred gas and water pipe for ductwork system between city and its suburb,

Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Process flow:

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → stacker

resistance, aging resistance, high mechanical strength, resistance of environmental stress cracks, resistance to creep

deformation, heat-linkage, and so on. So, it is a preferred gas and water pipe for ductwork system between city and its suburb,

Large diameter HDPE pipes start to play very important role in the city water and gas supply systems.

Process flow:

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → stacker

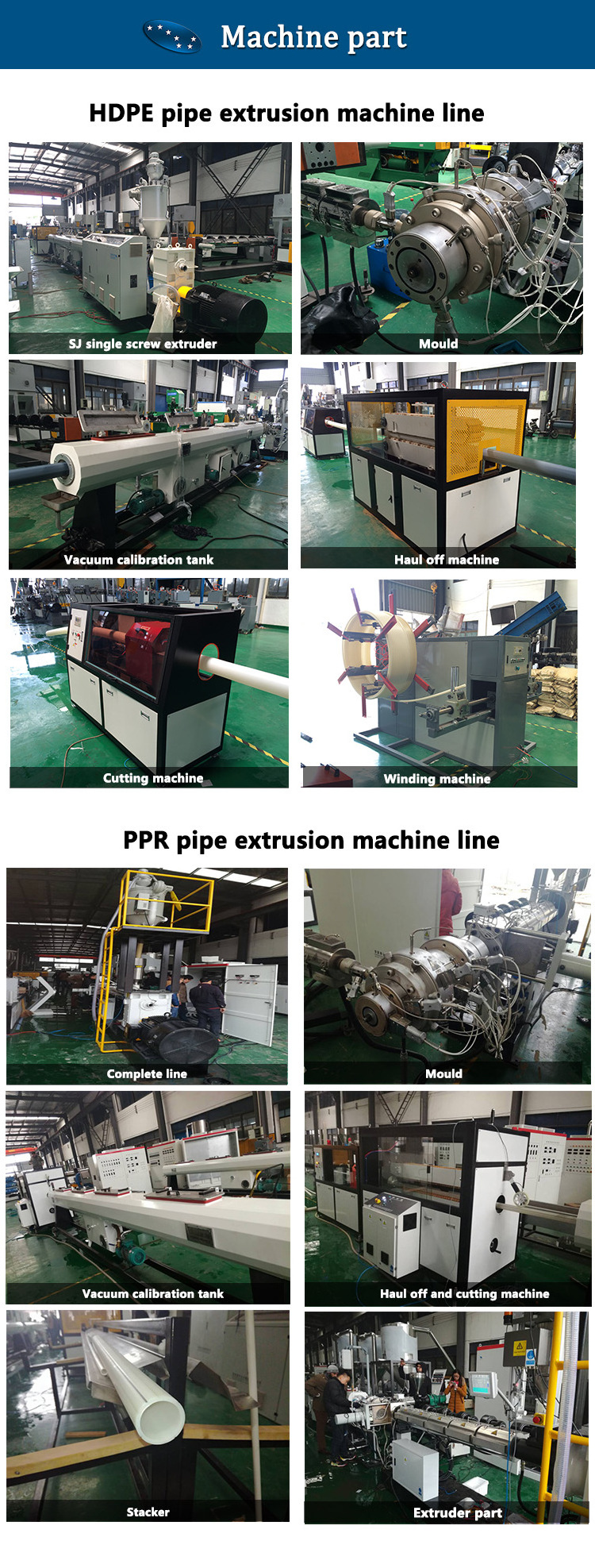

Specification

Model of

co-extrusion PPR pipe making machine production line

|

Model number

|

Pipe diameter (mm)

|

Max output (kg/hr)

|

Production rate (m/min)

|

Extruder model

|

Installation power

|

Layout dimension

|

|

PE16/63

|

16-63

|

150

|

1-15

|

SJ65/30

|

85kw

|

35x3x2m

|

|

PE20/110

|

20-110

|

200

|

1.2-12

|

SJ65/33

|

110kw

|

38x3.1x2.2m

|

|

PE50/160

|

50-160

|

350

|

0.6-8

|

SJ75/33

|

125kw

|

38x3.1x2.2m

|

|

PE75/250

|

75-250

|

350

|

0.5-4

|

SJ75/33

|

180kw

|

40x3.2x2.4m

|

Recommend Products

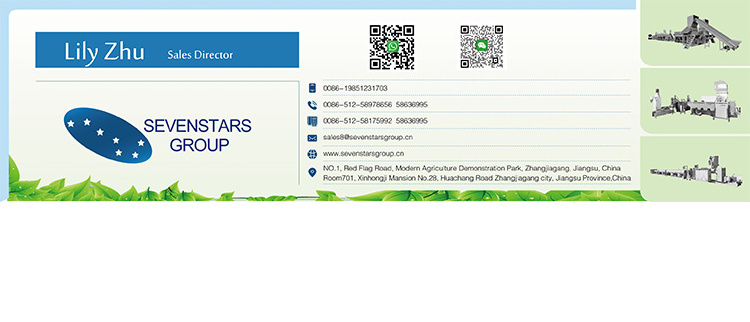

Contact us

Packing & Delivery

seaworthy packing with bubble film and strengthen film

Hot Searches