- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1150

-

Motor Power (kW):

-

14

-

Model:

-

YG-2

-

Single Wire Diameter:

-

Round steel 4-10mm

-

Double wire:

-

4-6mm

-

Max bending angle:

-

Within 180 degree

-

Center pin diameter:

-

16 18 20

-

Maximum towing speed:

-

60m per min

-

Maximum bending speed:

-

800 Degree

-

Machine size:

-

2600 800 1700mm

-

Device color:

-

Custom made

-

Product name:

-

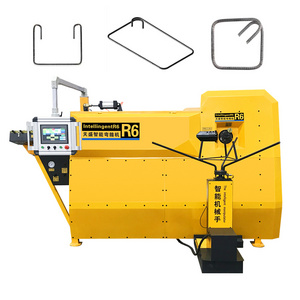

CNC Rebar Bending Machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUGONG MACHINERY

-

Year:

-

2023

-

Weight (KG):

-

1150

-

Motor Power (kW):

-

14

-

Model:

-

YG-2

-

Single Wire Diameter:

-

Round steel 4-10mm

-

Double wire:

-

4-6mm

-

Max bending angle:

-

Within 180 degree

-

Center pin diameter:

-

16 18 20

-

Maximum towing speed:

-

60m per min

-

Maximum bending speed:

-

800 Degree

-

Machine size:

-

2600 800 1700mm

-

Device color:

-

Custom made

-

Product name:

-

CNC Rebar Bending Machine

Product Description

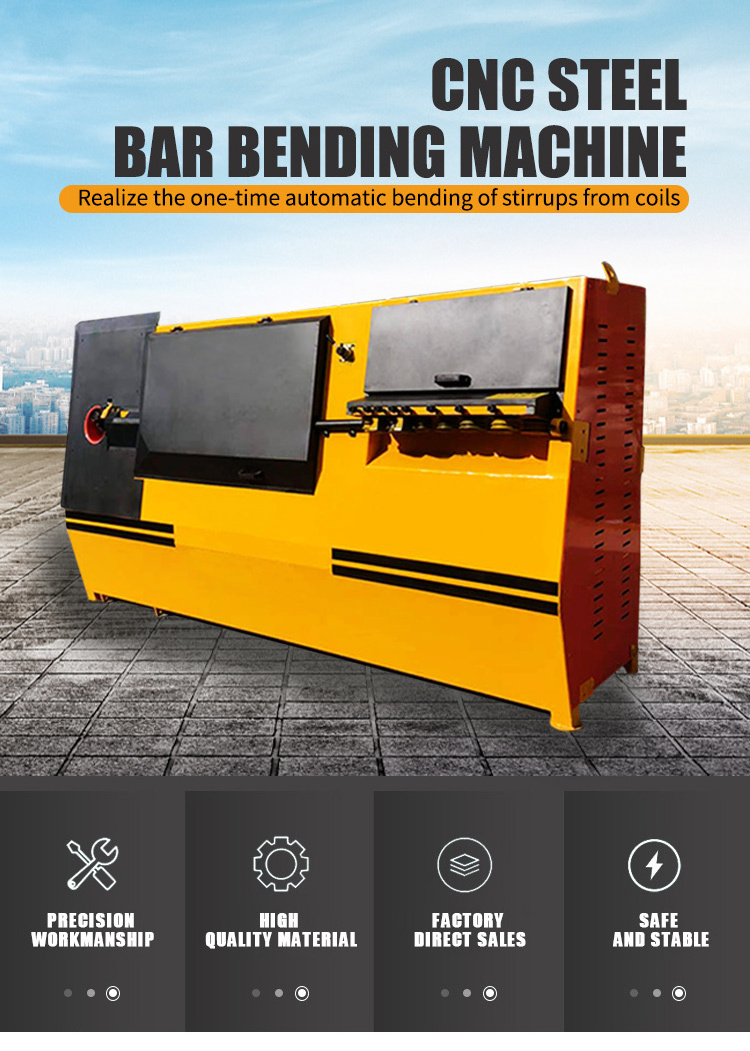

The CNC steel bar bending machine is mainly used in cold rolling and hot rolling of steel bars, construction, bridges, tunnels, prefabricated components and other engineering stirrup processing. The efficiency of the automatic steel bar bending machine is higher, which reduces the intensity of labor and liberates manpower

The CNC automatic hoop bending machine combines the mature frame-type rotary straightening system, digital meter, hydraulic cutting, hydraulic five-head bending hoop and other systems, through computer program control, to realize the one-time automatic bending of the coil (screw) into stirrups. Panyuan (panluo) does not need a wire rack, and the material is the same as that of ordinary straightening machines. It is very suitable for use on the construction site and is easy to adjust and maintain. Electric control system PLC industrial numerical control controller, touch screen operation, straightening speed automatically adapts to the speed of bending stirrups, cutting adopts sliding cutter, and there is no problem of aggravated wear of small stirrups. High production efficiency, each machine is equivalent to the work efficiency of 4-6 workers, and one worker can operate it.

Main features:

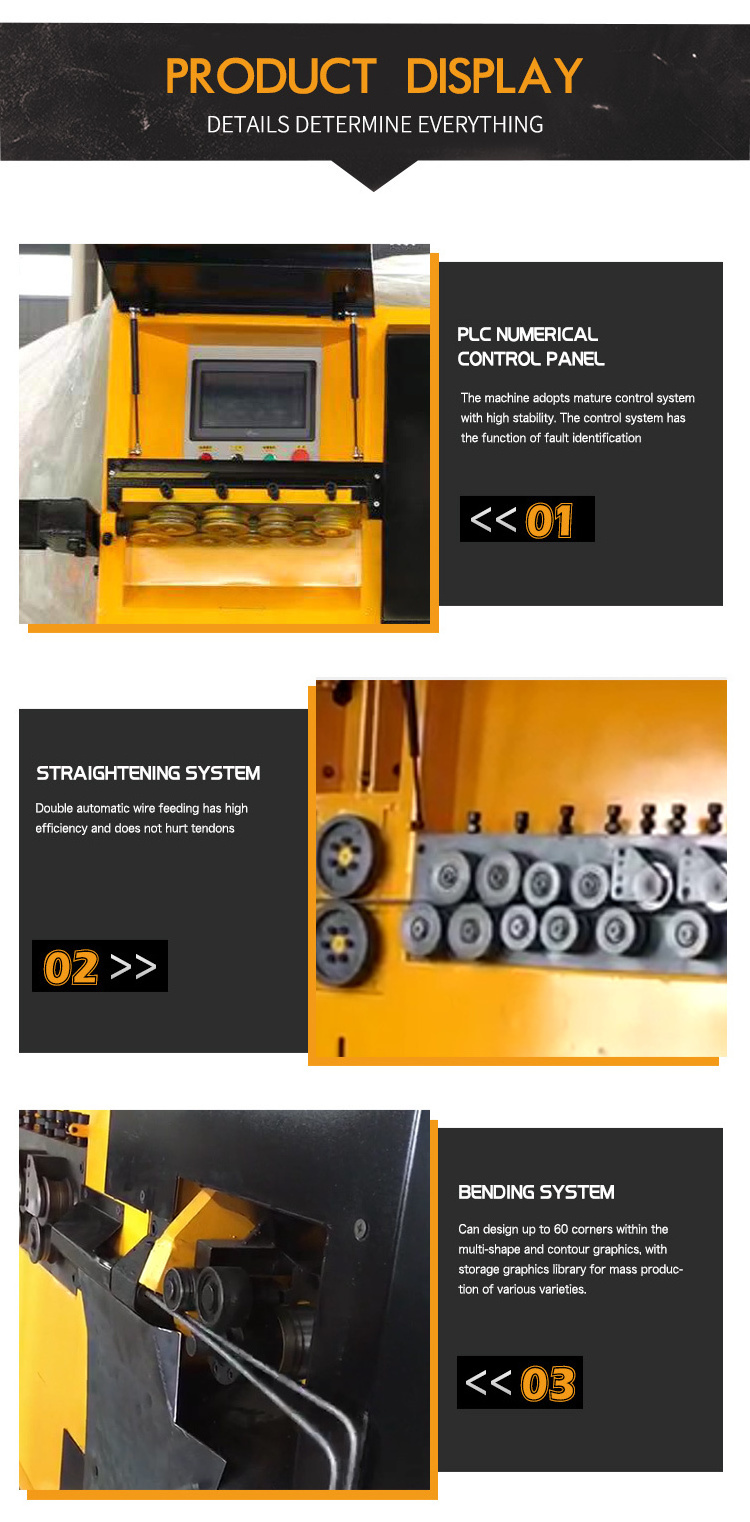

1. It consists of two sets of straightening wheels that can be automatically adjusted horizontally and vertically, combined with 4 traction wheels, driven by servo motors, to ensure the straightening accuracy of steel bars.

2. Bending and shearing mechanism: Driven by a servo motor, the bending arm can rotate and stretch at high speed, and the shearing mechanism quickly completes the shearing action to ensure the bending accuracy of the steel bar.

3. Control system: The machine adopts a mature control system with high stability. The control system has a fault identification function.

4. It can design multi-shaped ancient and modern and contour graphics within 60 corners, and has a storage graphics library for mass production of various varieties.

5. It can continuously produce the shape of the stirrup, without stopping halfway, without mechanical adjustment; and without interrupting the processing when correcting the bending angle.

Specification

|

Model

|

YG-1

|

YG-2

|

YG-3

|

YG-4

|

|||

|

Single wire(mm)

|

Round steel 4-10mm

Deformed steel bar 4-8mm

|

Round steel 4-12mm

Deformed steel bar 4-10mm

|

Round steel 5-14mm

Deformed steel bar 5-12mm

|

Round steel 4-12mm

Deformed steel bar 4-10mm |

|||

|

Double wire(mm)

|

Round steel 4-6mm

Deformed steel bar 4-6mm

|

Round steel 4-8mm

Deformed steel bar4-8mm

|

Round steel 5-10mm

Deformed steel bar 5-10mm

|

Round steel 4-8mm

Deformed steel bar 4-8mm |

|||

|

Max bending angle

|

±180°

|

|

|

|

|||

|

Center pin diameter

|

16、18、20

|

16、18、20

|

/

|

16、18、20

|

|||

|

Maximum towing speed

|

60m/min

|

60m/min

|

110m/min

|

110m/min

|

|||

|

Maximum bending speed

|

800°/sec

|

800°/sec

|

1000°/sec

|

800°/sec

|

|||

Packing & Delivery

Hot Searches