- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Solar junction box

-

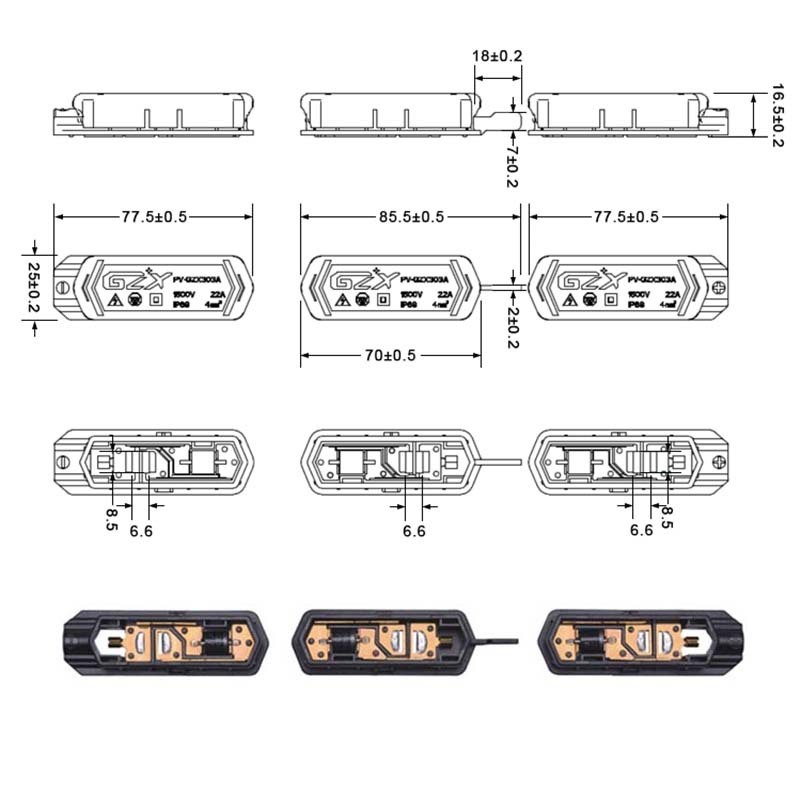

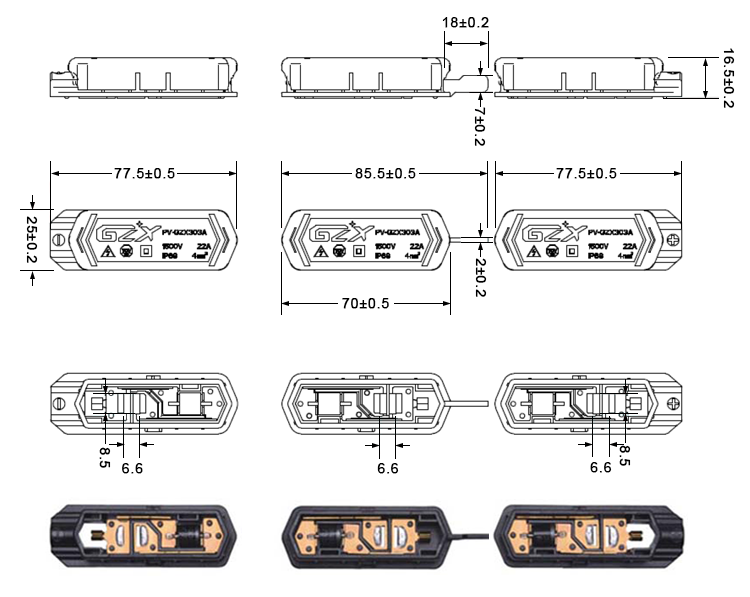

Size:

-

77.5*25*16.5mmX2, 85.5*25*16.5mmX1

-

Rated Voltage:

-

1500V

-

Rated Current:

-

22A/25A

-

Working Temperature Range:

-

-40℃~+85℃

-

IP Grade:

-

IP68

-

Safety Class:

-

Class II

-

Waterproof Structure:

-

Potting sealant

-

OEM&DOM:

-

Acceptable

-

Packing:

-

Bubble bag + Carton

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Solar Point

-

Model Number:

-

GZX303A

-

Product name:

-

Solar junction box

-

Size:

-

77.5*25*16.5mmX2, 85.5*25*16.5mmX1

-

Rated Voltage:

-

1500V

-

Rated Current:

-

22A/25A

-

Working Temperature Range:

-

-40℃~+85℃

-

IP Grade:

-

IP68

-

Safety Class:

-

Class II

-

Waterproof Structure:

-

Potting sealant

-

OEM&DOM:

-

Acceptable

-

Packing:

-

Bubble bag + Carton

OEM&ODM Services

Specification

|

Overall Dimension

|

77.5*25*16.5mm/2pcs, 85.5*25*16.5mm/1pcs

|

|

Rated Voltage

|

1500V(TUV)

|

|

Rated Current

|

22A/25A

|

|

Working Temperature Range

|

-40℃~+85℃

|

|

Safety Class

|

Class II

|

|

IP Grade

|

IP68

|

|

Waterproof Structure

|

Potting sealant

|

|

Volume of Potting Glue

|

24ml

|

|

Cable Cross Section Range

|

4mm²

|

|

Width of Ribbons

|

Up to 8mm

|

|

Height of Ribbons

|

7~9mm

|

|

Connection Method of Ribbon

|

Soldering

|

|

Center Line Spacing of Ribbon

|

5.2mm

|

|

Contact Material

|

Copper, Tin-plated

|

|

Insulation Material

|

PPO

|

|

Optional Connector

|

PV-GZX1500

|

Products Description

GZX303A

It

adopts full Potting-glue, waterproof, Out-door use design with TUV approval. Which will apply to the PV module of 156*156 mm cells with 6 ribbons. Meanwhile, The junction box can reduce PV module’s power consumption and improve electrical reliability.

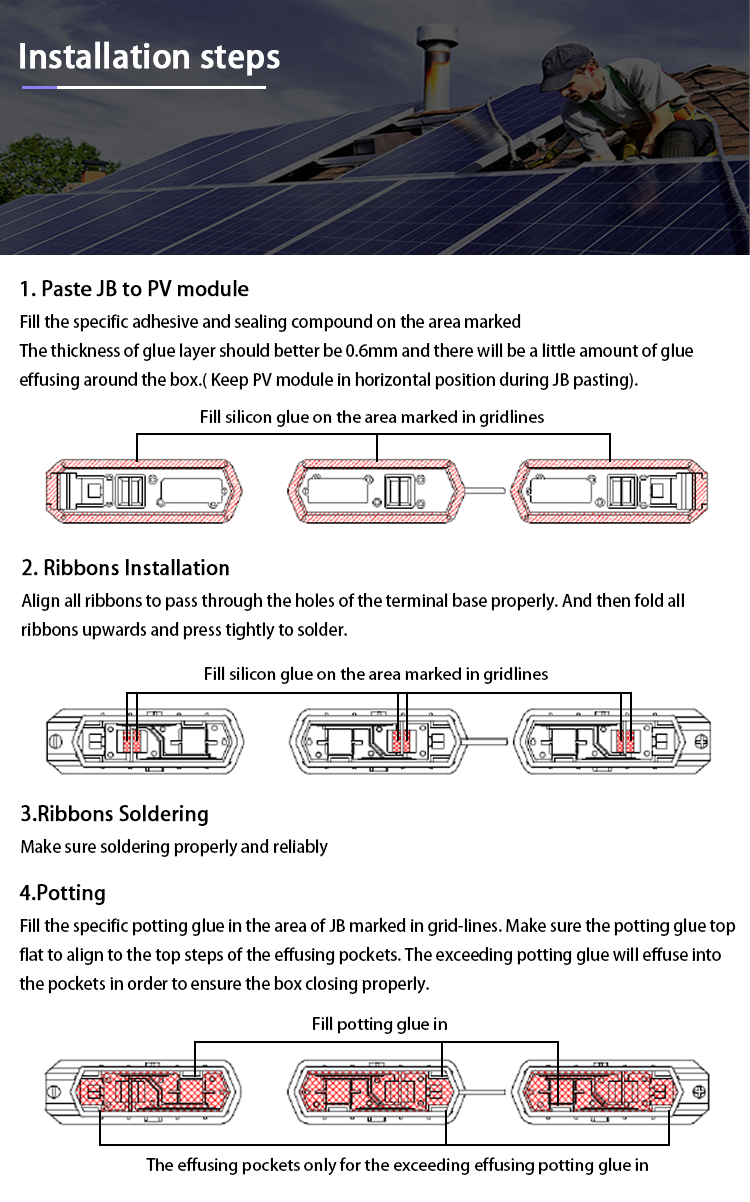

Installation Precautions

●

PV module’s ribbon alignment must be complied with JB’s mounting hole of the terminal base.

●

Adhesive and sealing compound, Potting glue must be applied by using specific type and specification. Make sure JB will be fixed in the correct position and reliable sealant. The potting glue level should be over the top surface of Diodes and terminal base. In order to avoid electrical shock risk.

●

Don’t move PV module or JB before adhesive and sealing compound or potting glue solidify.

●

Ensure soldering between Ribbons and terminal reliably in order to avoid missing soldering or false soldering. The soldering operators must be professionally trained. More soldering time will cause the diodes damaged.

●

Adopt anti-static protection solutions when touch or solder JB.

●

Make sure the connection method between JB and PV module in the correct polarity. Otherwise, Wrong connection will cause fire.

●

PV module manufacturer should inspect the diodes of JBs before shipment since the diodes might be damaged by heat temperature or the static shock. .

●

Installation or maintenance should be operated by the professional personnel.

●

For protection against electric shock, while being assembled or disassembled, make sure connectors isolated from the power supply.

●

Don’t connected or disconnected under load.

●

During the assembly process, keep the connector away from any corrosive materials.

More Products

Certifications

Hot Searches