This machine is widely used for filling liquid paste and viscous liquid products in food, medicine, chemical, daily chemical, petroleum, fishery, pesticide and other industries. Parts in contact with materials are made of high quality stainless steel.

1, The machine adopts adjustable filling valve, free to adjust the upper and lower distance, compact and reasonable design, simple and beautiful appearance;

2, servo motor drive, stable performance, accurate measurement;

3, automatic bottle feeding, filling, bottle out, no bottle filling;

4, filling volume is accurate, with counting function;

5, PLC programmable control, multi-directional parameter setting, powerful function;

6, all electrical components are imported brand, to ensure good quality, lasting and stable performance;

7, equipped with filling head, prevent drip drawing, to ensure no drip after filling;

8. Equipped with immersion filling system to ensure no foam in the filling process and prevent overflow.

9、Fast water flushing system, no need to disassemble equipment, easy cleaning.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤1g

-

Voltage:

-

220V /380V/50hz or 60hz

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GROUNTON

-

Dimension(L*W*H):

-

2000mm*1000mm*1400mm

-

Weight:

-

230 KG

-

model:

-

QGTX-1800

-

The weight of the:

-

330Kg

-

voltage:

-

220V/380V or ODM

-

Filling RANGE PER BOTTLE:

-

5-50pcs/min

-

speed:

-

1000-6000 BPH

-

Apply the bottleneck:

-

30-120mm

-

Apply high bottle:

-

40mm-300mm(customized on demand)

-

error:

-

±1g OR 1%

-

Overall dimensions:

-

1680mm*900mm*1800mm

-

After Warranty Service:

-

Video technical support

Quick Details

-

Machinery Capacity:

-

4000BPH, 6000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

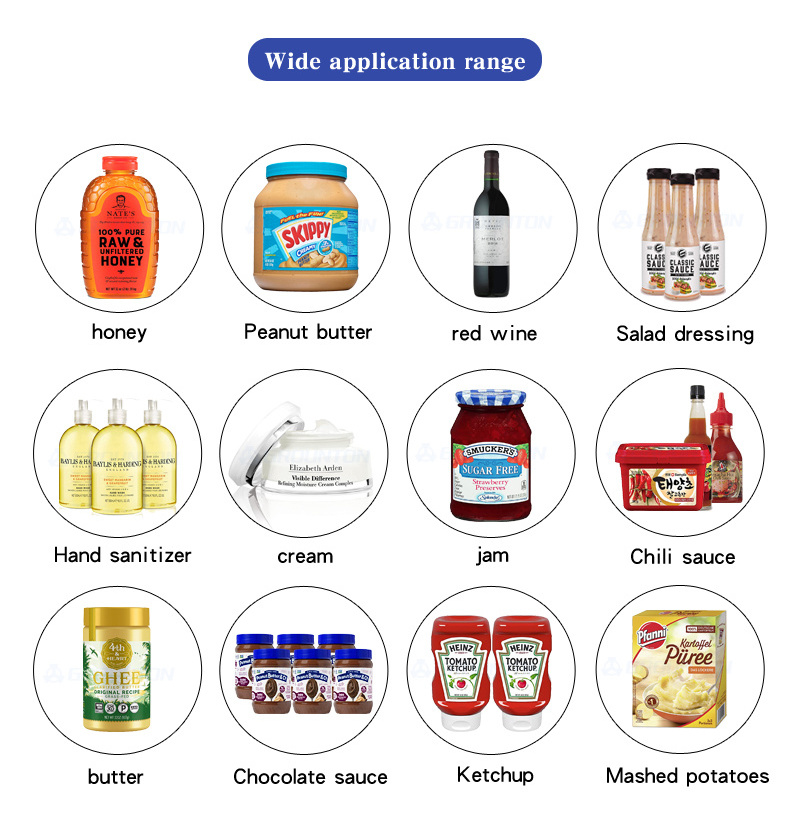

Beer, Milk, Water, Oil, Juice, honey, Peanut butter, red wine, Salad dressing, Hand sanitizer, cream, jam, Chili sauce, butter, Chocolate sauce, Ketchup, Mashed potatoes

-

Filling Accuracy:

-

≤1g

-

Voltage:

-

220V /380V/50hz or 60hz

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

GROUNTON

-

Dimension(L*W*H):

-

2000mm*1000mm*1400mm

-

Weight:

-

230 KG

-

model:

-

QGTX-1800

-

The weight of the:

-

330Kg

-

voltage:

-

220V/380V or ODM

-

Filling RANGE PER BOTTLE:

-

5-50pcs/min

-

speed:

-

1000-6000 BPH

-

Apply the bottleneck:

-

30-120mm

-

Apply high bottle:

-

40mm-300mm(customized on demand)

-

error:

-

±1g OR 1%

-

Overall dimensions:

-

1680mm*900mm*1800mm

-

After Warranty Service:

-

Video technical support

Introduction

osmetic filling machine – Accurate and fast filling solution

Alphapack cosmetic filling machine is a specialized equipment, used to fill cosmetics, thick liquids, medical fluids,… accurately and quickly. The machine is manufactured using modern technology, ensuring high quality and durability.

Advantages of Alphapack cosmetic filling machine

* Accurate filling, ensuring accurate filling volume, no missing or excess ingredients.

* Fast, up to 5-60 products/minute, meeting the production needs of many businesses.

* Easy to use and adjust volume changes, helping to save time and costs.

* The machine body is made of 304 or 316 stainless steel, ensuring food hygiene and safety.

* The machine has a warning system for missing jars or ingredients, ensuring product quality.

Alphapack cosmetic filling machine is a specialized equipment, used to fill cosmetics, thick liquids, medical fluids,… accurately and quickly. The machine is manufactured using modern technology, ensuring high quality and durability.

Advantages of Alphapack cosmetic filling machine

* Accurate filling, ensuring accurate filling volume, no missing or excess ingredients.

* Fast, up to 5-60 products/minute, meeting the production needs of many businesses.

* Easy to use and adjust volume changes, helping to save time and costs.

* The machine body is made of 304 or 316 stainless steel, ensuring food hygiene and safety.

* The machine has a warning system for missing jars or ingredients, ensuring product quality.

* Self-Cleaning by one key

Technical specifications of Alphapack cosmetic filling machine

* Application: Filling cosmetics, thick liquids, medical,Paste,sauce,Cosmetic…

* Speed: 0-60 products/minute

* Machine dimensions: (L1680 x W1400 x H1600) mm

* Electric capacity: 1.75kw/h

* Air pressure: less than 0.1 m3/min

* Power source: 220/380v/50hz

* Machine weight: 330kg

* Origin: Grounton – China

* Electrical components used: Germany, Japan, Taiwan, famous components

Application:

Alphapack cosmetic filling machine is widely used in the cosmetic and pharmaceutical industries…

Technical specifications of Alphapack cosmetic filling machine

* Application: Filling cosmetics, thick liquids, medical,Paste,sauce,Cosmetic…

* Speed: 0-60 products/minute

* Machine dimensions: (L1680 x W1400 x H1600) mm

* Electric capacity: 1.75kw/h

* Air pressure: less than 0.1 m3/min

* Power source: 220/380v/50hz

* Machine weight: 330kg

* Origin: Grounton – China

* Electrical components used: Germany, Japan, Taiwan, famous components

Application:

Alphapack cosmetic filling machine is widely used in the cosmetic and pharmaceutical industries…

Performance characteristics:

Range of application

This machine can be filled materials

1, food category: honey, jelly, juice, yogurt, milk, cream, ice cream, porridge, chili sauce, tomato sauce, sesame paste, maltose, meat, mustard, mashed potatoes, bean paste, salad sauce, chocolate, yeast, butter, animal fat, olive oil, wine.

2. Cosmetics: facial cleanser, face cream, hand cream, silica gel, aloe vera, nail polish, sunscreen, perfume, essence oil, toothpaste, gel, lotion, laundry detergent, hand sanitizer, shampoo, shower gel, bath salt.

3, other categories: poultry feed, pet rations, vaseline, syrup, glue, gelatin, normal saline, ink, eye drops, paint, etc.

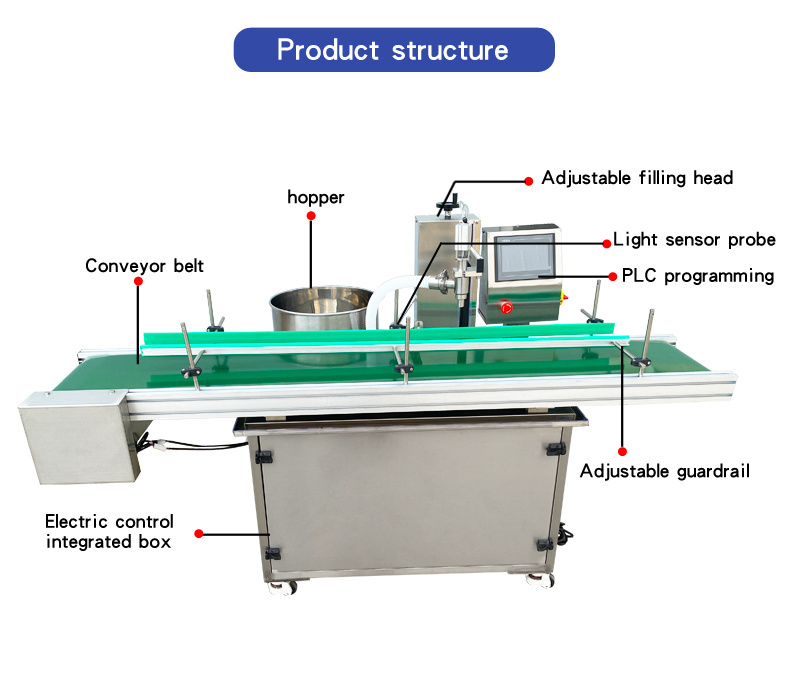

equipment

Product structure

This product is composed of conveyor belt, hopper, adjustable filling head, light sensing probe, PLC programming, adjustable guardrail and electronic control integrated box.

parameter

Product details

PLC touch screen control panel

Intelligent operation panel, touch screen version, can control the filling amount, filling speed, filling time, the parameters of each work module.

Air filter

Compressed gas filter, effective separation of compressed air impurities, water, oil, sediment, etc., to ensure the equipment clean air source.

Adjustable filling valve

Filling valve through the top hand wheel, rotating adjustment height, suitable for different height containers.

Light sensor probe

Adjustable light detector, accurate induction, no omission of filling bottle.

conveyor

Belt transmission, servo motor drive, stable transmission, speed adjustable.

Equipped with CAM rotor pump

The machine is equipped with CAM rotor pump, volumetric structure, stainless steel material, servo motor drive, accurate measurement, high stability.

Selection of filling valve

Selection of filling valve

Material viscosity is different, the nature is different, choose different filling valve.

Commonly used: filling nozzle can be replaced, can fill solid soft particles, oil and water separation, high viscosity materials.

Closed: can be filled flow paste, liquid materials, no particles.

Blowing: central blowing design, can fill the material with serious wire drawing.

Product display

Our company

Hebei GuangTeng Machinery Co.., Ltd. is a leading manufacturer and exporter of Rotary SS Lobe pumps & Servo Filling Machine integrating R&D, production and sales. Under the technical research and development department, to provide customers with product technology improvement and customization services. The core components of the product are all developed by It is manufactured by improved processing technology, which ensures the processing precision of each component of the product, as well as the working precision, and improves the working efficiency and quality of the product. Each production line is equipped with professional quality inspectors to Carry out rigorous testing to ensure that each set of products meets the standards. We specialize in the manufacture of a wide range of liquid fluid delivery equipment such as cam pumps, stainless steel food pumps, gear oil pumps, centrifugal pumps, screw pumps, diaphragm pumps, magnetic pumps and more. Our company can also produce qualified products To customers' customization. We have experienced technical team, advanced processing technology, strict inspection process, and provide competitive price and high quality products. Our products have a good market in the United States, India, the Middle East, Europe, Africa and other Countries and regions. Continuous innovation is the core development goal of the GROUNTON brand pump. We always focus on product quality, providing customers with professional technical services and excellent after-sales service. In order to build a global, branded product, we welcome every customer to develop with us. We welcome customers, business associations and friends from all over The world to contact us for cooperation and mutual benefit.

FAQS

1. What is the delivery period for the machine?

The delivery period for the machine is mainly within 30 days. If you

are in great hurry, please contact us for the details.

2. How about the after service and gurantee period?

We make the gurantee time 12 months from the machine's arrival in

buyer's facility and we have professional team with experienced

technician and do the best after service to assure the machine whole life uage.

Hot Searches